Calcined Anthracite Coal Carbon Raiser for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

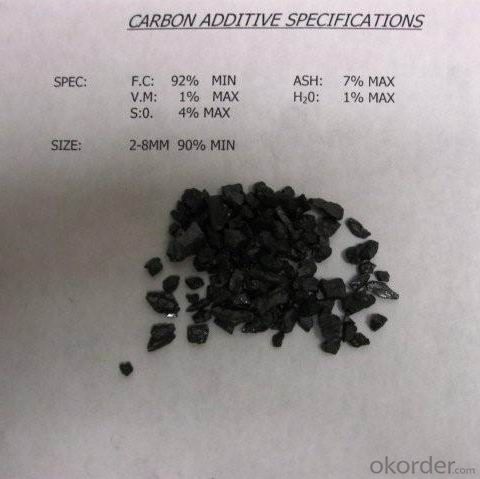

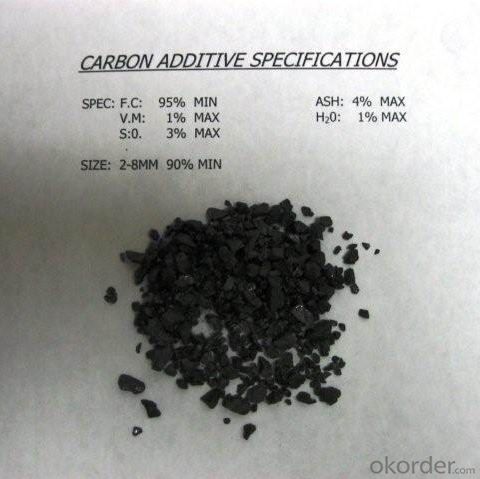

Specifications Calcined Anthracite Coal Carbon Raiser for Steelmaking Carbon Additve low Ash,S,P Structure Calcined Anthracite Coal Carbon Raiser for Steelmaking Shape: granule Dimensions: FC90-95% Product Type: Carbon Additive C Content (%): 90-95% MIN Working Temperature: - S Content (%): 0.5%MAX N Content (%): - H Content (%): 0.6%MAX Ash Content (%): 8.5%MAX Volatile: 2%MAX ADVANTAGE: low ash & sulfur COLOR: Black RAW MATERIAL: TaiXi anthracite Feature Calcined Anthracite Coal Carbon Raiser for Steelmaking Specifications (%): Grade F.C Ash V.M Moisture S Size CR-95 ≥95 <4 <1 <1 <0.3 0-30mm CR-94 ≥94 <4 <1 <1 <0.3 CR-93 ≥93 <6 <1 <1 <0.4 CR-92 ≥92 <7 <1 <1 <0.4 CR-91 ≥91 <8 <1 <1 <0.4 CR-90 ≥90 <8.5 <1.5 <2 <0.4 Image Calcined Anthracite Coal Carbon Raiser for Steelmaking FAQ: Calcined Anthracite Coal Carbon Raiser for Steelmaking Why we adopt carbon additive? Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation. Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking. Advantage: Calcined Anthracite Coal Carbon Raiser for Steelmaking 1.High quality and competitive price. 2.Timely delivery. 3.If any item you like. Please contact us. Your sincere inquiries are typically answered within 24 hours.

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

As buyer's request.

- Q:What are the properties of carbon nanotubes?

- Carbon nanotubes are cylindrical structures made entirely of carbon atoms. They have a unique set of properties that make them highly desirable in various fields of science and technology. Some of the key properties of carbon nanotubes include: 1. Exceptional strength and stiffness: Carbon nanotubes have an incredibly high strength-to-weight ratio, making them one of the strongest materials known to date. They are about 100 times stronger than steel but much lighter. This property makes them suitable for applications requiring lightweight but strong materials. 2. High electrical conductivity: Carbon nanotubes possess excellent electrical conductivity, allowing them to efficiently carry electrical current. They can be utilized as conductive components in various electronic devices, such as transistors, sensors, and energy storage systems. 3. Thermal conductivity: Carbon nanotubes exhibit high thermal conductivity, meaning they can efficiently conduct heat. This property makes them ideal for applications requiring efficient heat dissipation, such as thermal management in electronic devices. 4. Flexibility and resilience: Carbon nanotubes are highly flexible and can withstand significant deformation without breaking. They can be bent and twisted without losing their structural integrity, making them suitable for applications requiring flexibility, such as flexible electronics. 5. Unique optical and mechanical properties: Carbon nanotubes possess unique optical properties that vary depending on their structure and arrangement. They can absorb and emit light across a wide range of wavelengths, making them useful in applications like photodetectors and solar cells. Additionally, their mechanical properties, such as the ability to deform elastically, make them useful in applications requiring shock absorption and impact resistance. 6. Chemical stability: Carbon nanotubes are highly chemically stable, which means they can resist degradation or corrosion when exposed to various chemical environments. This property makes them suitable for applications in harsh conditions or as protective coatings. 7. Large aspect ratio: Carbon nanotubes have a high aspect ratio, with lengths often exceeding thousands of times their diameter. This characteristic allows them to form strong and lightweight composite materials when incorporated into a matrix, enhancing the overall strength and stiffness of the composite. Overall, the unique combination of properties exhibited by carbon nanotubes makes them an exciting and versatile material with immense potential for a wide range of applications, including electronics, aerospace, medicine, and energy storage.

- Q:Will long-term use of carbon alloy chopsticks cause cancer?

- Do chopsticks also cause cancer? Experts say, should not use too long, 3 to 6 months that change, pay attention to chopsticks material selection, use and maintenance. Have you noticed how often the chopsticks are changed at home? Recently, a news about the need for regular replacement of chopsticks, attracted the attention of Internet users. According to reports, hidden in the small groove in the chopsticks bacteria, may cause dysentery, gastroenteritis and other diseases, it is recommended that the public, chopsticks should be replaced at regular intervals of 3~6 months. This makes many people surprised, "used so many years chopsticks, do not know!"." Yesterday morning, in the south near Xi'an Renrenle supermarket shopping public Ms. Hao said. Subsequently, a random survey of 20 members of the public, of which 4 people said that in the six months of internal moving or kitchen renovation and replaced chopsticks. While the other 16 citizens, the number of chopsticks used in the home was 1~3 years. Especially for families with old people, chopsticks are updated more slowly. "The old man can't bear to throw it. He can't help it. Every time he comes to the restaurant, the chopsticks are not enough."." Liu said the public. In this regard, yesterday, director of the Xi'an Municipal Hospital of traditional Chinese Medicine Department of Gastroenterology physician Huang Yahui said, if the wood and bamboo chopsticks used for a long time, it is easy to breed bacteria sawdust loose.

- Q:What are the applications of carbon nanomaterials in medicine?

- Carbon nanomaterials have emerged as promising tools in the field of medicine due to their unique properties and potential applications. One of the key applications of carbon nanomaterials in medicine is in drug delivery systems. These nanomaterials can be functionalized with drugs, making them capable of targeted delivery to specific cells or tissues. The large surface area of carbon nanomaterials allows for more efficient drug loading, enabling improved therapeutic efficacy and reduced side effects. Carbon nanomaterials also show great potential in the field of tissue engineering. They can be used as scaffolds to support the growth and regeneration of damaged tissues. Carbon nanomaterials possess excellent mechanical strength and biocompatibility, making them suitable for applications such as bone and cartilage repair. Additionally, their electrical and thermal conductivity properties make them ideal for creating bioelectrodes and biosensors, which can be used for various diagnostic and monitoring purposes. Furthermore, carbon nanomaterials have been explored for their antimicrobial properties. They have shown the ability to inhibit the growth of bacteria and fungi, making them potential candidates for developing new antimicrobial agents. This could be particularly useful in preventing and treating infections in medical devices and implants. Another application of carbon nanomaterials in medicine is in imaging and diagnostics. These nanomaterials can be used as contrast agents in various imaging techniques, such as magnetic resonance imaging (MRI) and fluorescence imaging. Their unique optical and magnetic properties allow for enhanced imaging and improved detection of diseases, such as cancer. Carbon nanomaterials also hold promise in the field of cancer therapy. They can be used in photothermal therapy, where the nanomaterials are exposed to light, converting it into heat and selectively killing cancer cells. Additionally, carbon nanomaterials can be used in photodynamic therapy, where they generate reactive oxygen species upon light activation, leading to cancer cell destruction. In summary, carbon nanomaterials have a wide range of applications in medicine. They offer the potential for targeted drug delivery, tissue engineering, antimicrobial agents, diagnostic imaging, and cancer therapy. Continued research and development in this field hold great promise for revolutionizing medical treatments and improving patient outcomes.

- Q:How does carbon impact the growth and development of plants?

- Carbon is essential for the growth and development of plants as it is a key component of photosynthesis. Through this process, plants convert carbon dioxide into glucose, their main source of energy. Carbon also plays a crucial role in forming the structural molecules of plants, such as cellulose, lignin, and proteins. Overall, carbon is vital for the overall health, productivity, and survival of plants.

- Q:How does carbon impact biodiversity?

- Carbon impacts biodiversity in several ways. Firstly, carbon dioxide is a greenhouse gas that contributes to climate change, leading to shifts in temperature and precipitation patterns. These changes can disrupt ecosystems and alter habitats, affecting the distribution and survival of various species. Additionally, excess carbon in the atmosphere can lead to ocean acidification, which negatively affects marine biodiversity by harming coral reefs and other organisms reliant on calcium carbonate structures. Finally, deforestation and land-use changes associated with carbon emissions result in habitat loss, further reducing biodiversity. Overall, carbon emissions have significant and detrimental impacts on the delicate balance of ecosystems and the diversity of life on Earth.

- Q:Process for producing carbon fiber board

- Method for making carbon fiber sheet:1, first determine the thickness of the plate to be made2 calculate the required number of plies according to the thickness3, and then according to 0 degrees, 45 degrees, 90 degrees, -45 degrees in the order of stacking.4, and then molding it!Now carbon fiber board, in fact, many in the middle are entrained with some glass fiber cloth, of course, there are all carbon, a little more expensive!

- Q:What can light hydrocarbon carbon five be packed with?

- The stove is rated 1000 + 200Pa, outdoor transmission and distribution pipe network according to the number of users determine the diameter of the smallest diameter, 108mm diameter, maximum diameter 325mm, are made of seamless steel pipe or special gas PE pipe, outdoor pipe network by welding or hot melt connection method, the indoor pipeline for galvanized pipe, mainly adopts threaded connection. The design and construction are the same as that of the natural gas pipeline network. If the natural gas is replaced, it can be butted with the natural gas pipe mouth, and the indoor and outdoor pipe network need not make any change.

- Q:What is carbon nanowire?

- Carbon nanowire is a nanoscale structure composed of carbon atoms arranged in a wire-like shape, which exhibits exceptional electrical, thermal, and mechanical properties.

- Q:What is the concept of carbon equivalent? What is the relationship between carbon equivalent and weldability?

- In order to facilitate the expression of strength properties of these materials and welding performance simply to carbon equivalent to said through the statistics of test data.

- Q:How is carbon used in the production of cosmetics?

- Cosmetics utilize carbon in diverse ways during their production. A prevalent application of carbon in cosmetics involves its use as a coloring agent. Carbon black, a specific form of carbon, imparts a deep black hue to numerous cosmetic products such as eyeliners, mascaras, and eyeshadows. Nail polishes and lipsticks also incorporate carbon as a colorant. Furthermore, carbon finds application in the creation of activated charcoal, which has gained popularity due to its detoxifying properties. Derived from carbon, activated charcoal features prominently in skincare products like face masks, cleansers, and scrubs. Its ability to absorb excess oil and impurities from the skin makes it a favored ingredient for products targeting oily and acne-prone skin. Moreover, carbon contributes to the manufacturing of exfoliating products. Tiny particles known as microbeads, utilized in facial scrubs and body washes to eliminate dead skin cells, can be crafted from carbon. These microbeads gently exfoliate the skin, leaving it rejuvenated and smooth. Additionally, carbon plays a role in the production of certain cosmetic base materials. Emollients, crucial substances that moisturize and soften the skin, rely on carbon as an essential component. Creams, lotions, and lip balms commonly contain emollients, which enhance their hydrating properties. To summarize, carbon assumes a vital role in cosmetic production. Its versatility as an ingredient contributes to the aesthetics and functionality of various cosmetic formulations, ranging from providing color to enhancing the efficacy of skincare products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Calcined Anthracite Coal Carbon Raiser for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords