CA factory/ Calcined Anthracite Coal factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Professional Manufacturer,exporter of Calcined Anthracite Coal;

High quality with best price.

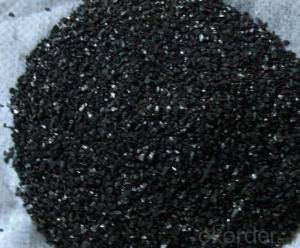

Calcined Anthracite Coal

• Calcined Anthracite Coal Feature:

All of our goods are made in the best quality with high carbon, low ash, low Sulphur, low moisture.

• Calcined Anthracite Coal Application:

Calcined anthracite coal/gas calcined anthracite coal/carbon raiser is mainly used in steelmaking in electrical stove, screening water, shipbuilding sandblast to remove rust. It can reduce the cost of steelmaking effectively by replacing the traditional petroleum coke of carburant. Also, it can improve the carbon content in steel melting and ductile iron foundry.

• Calcined Anthracite Coal Specifications:

Item | Fixed Carbon %(min) | Ash %(max) | Sulphur %(max) | Moisture %(max) | Volatile %(max) |

FQ-95 | 95 | 4.5 | 0.25 | 0.3 | 1.0 |

FQ-94 | 94 | 5.0 | 0.25 | 0.3 | 1.0 |

FQ-93 | 93 | 6.5 | 0.30 | 0.5 | 1.2 |

FQ-92 | 92 | 7.0 | 0.30 | 1.0 | 1.2 |

FQ-90 | 90 | 8.5 | 0.35 | 1.0 | 1.5 |

Size: 0.5-3mm, 1-4mm, 0.5-4mm, 1-3mm or as customers’ requests. | |||||

• Calcined Anthracite Coal Package:

In 25kgs or 50kgs small bag of single packing;

Or small bags onto pallet or Jumbo bag;

Or as customers’ requests.

- Q:The difference between ginger and roasted ginger ginger charcoal.

- In the processing practice, etc. in sand with fried for good, hot method has uniform heating, the advantages of uniform processing degree. And the processing time is short, less loss. Ginger charcoal should be a good fried (fried carbon method), easy to deal with. Because the processing degree, ginger carbonization less loss rate is generally 20%, while ginger carbonization, the loss rate is as high as 40%, resulting in higher costs.

- Q:What is the difference between white and black peat

- The "black peat" is more dense, but it is not suitable for the production of humic acid and humic acid fertilizer.

- Q:How many tons of coal can be produced by 1 tons of coal? What is the proportion of them in general?

- General boiler combustion ash is two parts, part of the flue gas to the end of the boiler exhaust by the dust collector, in addition to conventional fly ash; another part of the slag from the bottom of the furnace cooling after the discharge, conventional said slag. Different types of boilers are different in proportion to large power plants, for example, about 90% of fly ash, slag is about 10%

- Q:Bamboo charcoal package to how long exposure

- Drying is a key, generally 2-3 hours. It's better to be exposed to the sun. Please refer to the relevant details of the Advisory nest activated carbon

- Q:I would like to ask what is the pit coal?

- It is probably through the shaft or inclined shaft mining coal,

- Q:What is the use of power coal

- With the coal category, mainly lignite, long flame coal, non caking coal, lean coal and a small amount of anthracite. From the commodity coal, the main washing mixed coal, washed coal, coal, coal, etc.. The poor quality coal mainly refers to the low ash value (less than 40%) which is unfavorable to the operation of the boiler (less than 15). Bituminous coal of 73 MJ / kg, anthracite with low volatile content (less than 10%), lignite with high moisture content and high sulfur content (more than 2%), etc..

- Q:How does coal rank?Level, price

- Anthracite: high fixed carbon content, high fire point (about 360 to 420 DEG C), high true relative density (1.35 ~ 1.90), low volatile yield and low hydrogen content. In addition to power generation, anthracite is mainly used as raw material for gasification (fixed bed gasifier) for the production of synthetic ammonia, fuel and briquette

- Q:Coal water slurry is used for what?

- Coal water slurry is widely used in power plant boilers, industrial boilers and industrial furnaces instead of oil, gas, coal combustion and hotels, residential, hotels, office buildings and other buildings heating and domestic hot water.

- Q:What are the types of low rank coals? What is commonly used at present? Where can I buy

- First classification: (power coal in the following)... More, slowly lookTypes of coal (according to the degree of carbonization)1 peat (Caomei, peat) 8380~10500kJ/kg2 lignite 10500~16700kJ/kg3 bituminous coal 21000~29400kJ/kg4 anthracite (anthracite) 21000~25200kJ/kg

- Q:A 10 ton steam boiler runs for about 24 hours a dayHow many cubic meters per day do you have to burn the fuel, and how many kilograms of diesel oil should be fired per hour of the oil boiler 10T?

- Industrial steam 1.0MPA, 270 degrees, for example, the amount of evaporation of 10 tons / hour of heat for the 30 Ji Jiao. Boiler efficiency by the calculation of 60%, the need to burn coal of coal tar of 50

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CA factory/ Calcined Anthracite Coal factory

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords