Fiberglass Mat Tissue C-Glass Chopped Strand Mat Fiberglass Raw Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 600000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form(or other binder in emulsion form). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP molding, such as: various sheets and panels, boat hulls, cooling towers, corrosion resistant, vehicles etc.

Product Function

Fiberglass chopped strand mat is chopped using the “E” chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturated polyester resins.

Packaging & Delivery of C-glass Chopped Strand Mat

Packaging Detail: | cartons and pallets |

Delivery Detail: | within two weeks |

Main Features of C-glass Chopped Strand Mat

C-glass fiber chopped strand mat:

1. good wet-out

2. evenly distribution of fiber and binder

3. high mechanical strength etc.

Specification C-glass Chopped Strand Mat

We could provide E-Glass Powder Chopped Strand Mat and E-Glass Emulsion Chopped Strand Mat.

Specs | Roll length(m) | Width(mm) | Roll weight(kg) | Compatible Resin |

EMC225 | 1040mm | 144 | 30 | UP VE |

EMC300 | 1040mm | 96 | 30 | UP VE |

EMC380 | 1040mm | 80 | 30 | UP VE |

EMC450 | 2080mm | 64 | 60 | UP VE |

EMC600 | 2080mm | 48 | 60 | UP VE |

EMC900 | 2080mm | 32 | 60 | UP VE |

The products is raw material to produce FRP products.

Binder type: Emulsion or Power

Packing: by carton or by pallet, or as your requested

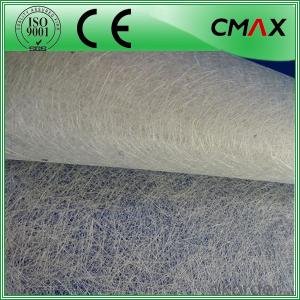

Pictures of C-glass Chopped Strand Mat

- Q: Can fiberglass mat tissue be used for creating molds?

- Using fiberglass mat tissue for creating molds is not possible. Fiberglass mat tissue is primarily utilized as a reinforcement layer in fiberglass composite applications due to its thin and lightweight nature. It is not intended to be used as a material for making molds. Instead, molds are commonly made using silicone, resin, or plaster, as these materials have the capacity to capture intricate details and offer a polished surface finish.

- Q: What are the typical dimensions and roll sizes of fiberglass mat tissue?

- Fiberglass mat tissue dimensions and roll sizes may vary depending on the product and manufacturer. Typically, rolls of fiberglass mat tissue come in widths ranging from 1 to 6 feet and lengths ranging from 100 to 1000 feet. The thickness of the tissue can range from 0.5 to 1.5 millimeters. Certain manufacturers may provide tailored sizes and lengths to meet specific project needs. To obtain the precise dimensions and roll sizes of fiberglass mat tissue, it is advisable to consult the manufacturer or supplier.

- Q: Can fiberglass mat tissue be used for insulation in shopping malls?

- Yes, fiberglass mat tissue can be used for insulation in shopping malls. It is a common and effective material for thermal insulation due to its low thermal conductivity and high resistance to heat transfer. Fiberglass mat tissue is also non-combustible, making it a safe option for commercial buildings like shopping malls. Additionally, it is lightweight, easy to install, and has excellent sound absorption properties, which can help in creating a comfortable and quiet environment within the mall. Overall, fiberglass mat tissue is a suitable choice for insulation in shopping malls, providing energy efficiency and improved indoor comfort.

- Q: How does fiberglass mat tissue perform in terms of heat insulation?

- Fiberglass mat tissue exhibits a relatively satisfactory performance when it comes to heat insulation. Its composition, consisting of delicate glass fibers and a bonding agent, grants it commendable thermal resistance properties. These fibers effectively capture pockets of air, which function as thermal barriers by diminishing heat transfer. Consequently, fiberglass mat tissue emerges as an appropriate insulation material for a diverse range of applications, including the construction industry, where it is employed to insulate walls, roofs, and attics. Furthermore, fiberglass mat tissue finds extensive use in the automotive and aerospace sectors to insulate engine compartments and curtail heat transfer through vehicle panels, respectively. Nevertheless, it is worth noting that although fiberglass mat tissue offers exceptional thermal insulation, it may not be as efficient as alternative insulation materials like foam or mineral wool, which possess higher thermal resistance values. Ultimately, the suitability of fiberglass mat tissue as an insulation material hinges upon the specific requirements of the project at hand.

- Q: Can fiberglass mat tissue be used for flooring applications?

- Yes, fiberglass mat tissue can be used for flooring applications. Fiberglass mat tissue is a thin, non-woven fabric made from glass fibers. It is lightweight, flexible, and has excellent strength and durability. These properties make it suitable for various flooring applications. Fiberglass mat tissue can be used as a reinforcement layer in flooring systems, such as vinyl or linoleum flooring. It provides added strength and stability to the flooring, preventing it from cracking or warping over time. The mat tissue is typically embedded in a layer of adhesive or resin, creating a strong bond between the flooring material and the subfloor. Additionally, fiberglass mat tissue can be used as an underlayment for flooring installations. It acts as a barrier between the subfloor and the flooring material, providing insulation, soundproofing, and moisture resistance. This helps to protect the flooring from moisture damage, reduce noise transmission, and maintain a comfortable indoor environment. Overall, fiberglass mat tissue is a versatile material that can enhance the performance and longevity of flooring applications. Its strength, flexibility, and resistance to moisture make it a suitable choice for various flooring systems, providing added stability, durability, and comfort.

- Q: Is fiberglass mat tissue suitable for insulation in data centers?

- Fiberglass mat tissue can be suitable for insulation in data centers, depending on specific requirements and considerations. Fiberglass mat tissue is a type of fiberglass insulation that is commonly used for thermal and acoustic insulation purposes. It offers several advantages such as high thermal resistance, fire resistance, and sound absorption capabilities. In data centers, insulation plays a crucial role in maintaining a controlled and stable environment for the sensitive electronic equipment. Fiberglass mat tissue can help in reducing heat transfer, preventing the occurrence of hot spots, and maintaining the desired temperature levels within the data center. It can also contribute to noise reduction, which is important in reducing distractions and ensuring a comfortable working environment for the personnel. However, there are certain factors that need to be considered before determining the suitability of fiberglass mat tissue for insulation in data centers. Firstly, the specific requirements of the data center in terms of thermal insulation, fire resistance, and acoustic control should be thoroughly evaluated. Additionally, the installation process and maintenance requirements should be assessed to ensure that the insulation material can be effectively implemented and maintained in the data center's infrastructure. It is also important to consider alternative insulation options such as mineral wool, foam insulation, or other specialized materials that may better suit the unique demands of data centers. These materials might offer specific advantages like better fire resistance, moisture control, or higher thermal efficiency. Ultimately, the suitability of fiberglass mat tissue for insulation in data centers depends on a comprehensive evaluation of the specific needs, regulatory requirements, and available options. Consulting with experts in the field of data center construction and insulation can provide valuable insights and help in making an informed decision.

- Q: Can fiberglass mat tissue be used in wet environments?

- Yes, fiberglass mat tissue can be used in wet environments. It is resistant to water and can withstand exposure to moisture without losing its structural integrity.

- Q: How does fiberglass mat tissue perform in terms of thermal resistance?

- Fiberglass mat tissue performs exceptionally well in terms of thermal resistance. Due to the inherent properties of fiberglass, such as low thermal conductivity and high melting point, the mat tissue effectively acts as a barrier against heat transfer. It efficiently blocks the conduction of heat, limiting thermal energy from passing through the material. This makes fiberglass mat tissue an excellent choice for insulation applications where thermal resistance is crucial, such as in buildings, industrial equipment, and automotive components. Additionally, fiberglass mat tissue is known for its fire-resistant properties, further enhancing its ability to withstand high temperatures and provide excellent thermal insulation.

- Q: Is fiberglass mat tissue suitable for HVAC insulation?

- Fiberglass mat tissue is indeed a suitable material for HVAC insulation. It is a lightweight and flexible substance commonly utilized in insulation applications due to its exceptional thermal insulation properties. With its effective heat insulation, it assists in maintaining a comfortable and energy-efficient environment within HVAC systems. Moreover, fiberglass mat tissue's resistance to moisture prevents the growth of mold or mildew, making it an appropriate choice for HVAC insulation in areas where condensation and moisture may occur. Its easy installation and ability to be cut to fit around HVAC components ensure a proper and secure insulation seal. In summary, fiberglass mat tissue is a dependable and long-lasting insulation material extensively employed in HVAC systems to enhance energy efficiency and thermal performance.

- Q: Can fiberglass mat tissue be painted over?

- Indeed, fiberglass mat tissue can be painted on. Nevertheless, there are a few factors that necessitate consideration. Firstly, it is imperative to ensure the cleanliness and absence of any dirt, grease, or contaminants on the fiberglass mat tissue prior to painting. This can be accomplished by washing the surface with a gentle detergent and water, followed by thorough rinsing and drying. Secondly, it is advisable to apply a primer before painting in order to enhance adhesion and achieve a smoother finish. It is recommended to utilize a high-quality primer specifically formulated for fiberglass surfaces, adhering to the manufacturer's instructions for application. Lastly, when selecting the paint, it is crucial to choose one that is compatible with fiberglass materials. Acrylic or epoxy-based paints are often suggested as they exhibit good adhesion and durability on fiberglass surfaces. By adhering to these steps and employing appropriate materials, it is feasible to successfully paint over fiberglass mat tissue. Nevertheless, it is always prudent to seek advice from a professional or follow the manufacturer's recommendations for optimal outcomes.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1969 |

| Annual Output Value | Above US$ 150 Million |

| Main Markets | overseas companies in Hongkong, Canada, South Africa, South Korea, India, Italy, Singapore, France and many other countries and regions. |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English |

| b) Factory Information | |

| Factory Size: | Above 5000,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | |

| Product Price Range | Average |

Send your message to us

Fiberglass Mat Tissue C-Glass Chopped Strand Mat Fiberglass Raw Material

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 600000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords