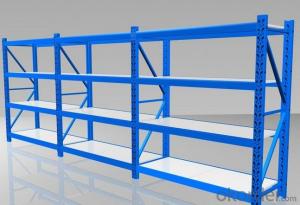

Beam Type Racking Systems for Warehouses

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Beam type pallet racking system has simple structure of upright and beam and reliable strucuture.

Goods for storage and carrying has no limits. It's usually used in pallet storage and forklift warehouse.

The beam and upright profiles are well produced by roll forming techonogy and fine steel is used for the manufacture.

It consists of upright, beam, strut.It forms structure by C upright and weld beam. It has 75mm adjustment range.

The system can be customized designed to the warehouse condition.

Feature:

· Large loading weight

· Customized design

· Professinal service

Images:

Specification:

Loading weight | 5000KG/layer |

Height | 12 M customized |

FAQ:

What is note for purchase?

Pallet size,good weight, warehouse sapce and height, forklift details, etc.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation.

- Q:What are the irrational aspects of warehousing in logistics?

- Serialization of logistics services. Modern logistics emphasizes the proper positioning, improvement and serialization of logistics service functions. In addition to the traditional storage, transportation, packaging, distribution processing and other services, modern logistics services to expand to the market investigation and prediction, purchasing and processing orders in the extension and extends downward to the distribution, logistics consulting, logistics project selection and planning, inventory control policy recommendations, payment and settlement, education and training etc. the connotation of value-added services; increased support services above the decision.

- Q:What are the advantages of automated warehousing and its role in logistics systems?

- Information flow and logistics can not be unified in time. On the one hand, the traditional warehouse is often low level of information technology, resulting in low level of overall logistics management, unable to provide customers with high-quality and flexible logistics services. On the other hand, because of the information flow and logistics can not be unified, resulting in the error costs described above, so that the overall cost of warehousing increased.

- Q:The difference between electricity supplier logistics and traditional logistics warehousing management

- (1) a large quantity of traditional logistics warehouse, you can use the forklift to pick goods directly, picking the goods, the efficiency is measured by the number of bins (the original packing box). The picking process is to pick the fruit directly or to seed after picking. An order quantity is large enough to consider how the order is formed.(2) the electricity supplier needs to the scale of victory, a wide variety, but the number of digits, even for a two, when picking an order is clearly not enough to pick the fruit, and consider the need to wave as a unit, while picking fruit while sowing. Therefore, the electricity supplier picking way is RF, picking cart, turnover box.

- Q:What are the storage facilities and equipment included?

- When the warehousing industry exists as a format, logistics is an effective means to realize value-added services, and warehousing is an indispensable node in the logistics industry.The development of modern logistics industry needs the support of modern warehouse management, and the advanced technology of informatization and the guidance of information technology has become an effective way for the warehousing industry to modernize.

- Q:What are the logistics and warehousing equipment? The more, the better

- Plastic tray tray, wooden pallets, steel pallets, storage cage, tchouk frame, logistics trolley, forklift cage, shelves of light, medium, heavy.

- Q:What is lean storage?

- The reasonable optimization of warehouse management can not only improve the delivery rate of products, but also ensure the efficiency of warehouse utilization. So what is the specific way? We need to make use of the convenience brought by the information age to improve the efficiency of warehouse management, and make the lean production management process more standardized and intelligent. Here comes a simple analysis of warehouse management skills.

- Q:What are the responsibilities of the warehouse and logistics department?

- (1) manage the material storage of the company.(2) responsible for the warehousing, delivery, storage and maintenance of the logistics department, and the safety management of the warehousing process.Warehousing of materialsLogistics Department of materials storage must strictly implement the company material storage process, other units shall formulate internal storage of materials flow, according to the purchase order or receive documents for the goods to the "product qualification certificate", "material certificate, packing mark, warning mark, packing list, check the appearance of the product and the number of check.To the library materials must be completed within 4 hours of data entry, there are batch requirements of materials must be input batch information, all materials to the library must have storage records.

- Q:What are the third party logistics? What are the advantages and disadvantages?

- Enterprises can concentrate on engaging in their own familiar business, the allocation of resources in the core businessBusinesses focus on the core business. Due to limited resources, it is difficult to become an expert on top of the business. For this reason, enterprises should concentrate their resources on the main industries which are good at it, and leave the auxiliary functions such as logistics to the third party logistics companies.

- Q:What are the main differences between the electricity supplier warehouse and the traditional warehouse?

- Average order lines are few. Traditional retail logistics has dozens, even more, hundreds of orders line, these goods may be distributed in all corners of the warehouse, according to order picking, warehouse go round to complete order picking. But only a few of the electricity supplier logistics orders, in most cases such as Jingdong, such as dangdang is no more than 10, a few such as shop No. 1 will be between 10 to 20, if still use the traditional retail logistics commonly used to order not picking, picking up for each trip only a few parts need to go a large number of road in the warehouse. A large number of actual combat statistics show that as much as 70% of the time spent in the picking process is on walking. Therefore, it is necessary to design a picking order, and can complete multiple orders at the same time, to improve the efficiency of picking, such as first picking, picking, planting, or picking the same model.

- Q:What are the problems in e-commerce, logistics and warehousing?

- The development of e-commerce depends to a large extent on the logistics enterprises to maintain high quality of service and flexibility, and control and reduce the cost of logistics. But in the logistics industry, some enterprises are empty of vehicles, idle warehouses, while many enterprises are looking for vehicles and warehouses. This shows that the social freight and warehousing resources are not short, and the lack of integration resources between enterprises. Therefore, the application of logistics technology now, the electronic commerce logistics enterprises scattered alliance, forming a service network, is the best way to reduce the cost of logistics and distribution, e-commerce to improve the level of development of e-commerce logistics.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Beam Type Racking Systems for Warehouses

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords