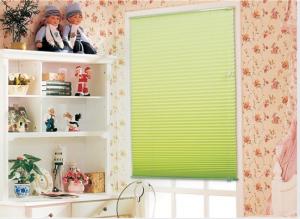

Anti Static PVC Strip Curtains in Green Color

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Factory-sale Anti-static PVC Strip Curtains

Application tempt range: -15℃to 50℃

Thickness range from 1.5mm to 6mm

Width range from 150mm to 400mm

Standard Sizes

2mmX200mmX50m; 2mmX300mmX50m;

3mmX200mmX50m; 3mmX300mmX50m;3mmX400mmX50m

4mmX300mmX50m; 4mmX400mmX50m

Applications of Factory-sale Anti-static PVC Strip Curtains

Widely used in electronics, food, pharmaceutical, refrigeration industry.

Can be used as barrier wall,protective portiere/curtain for sensitive area or protective cover for sensitive industry.

Package& Delivery of Factory-sale Anti-static PVC Strip Curtains

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale Anti-static PVC Strip Curtains

Green,Clear.

Data sheet of Factory-sale Anti-static PVC Strip Curtains

Performance Text | Standard Clear Formula | Cold Formula | Super Polar Curtain | Unit |

Softness A Hardness | 75+-5 | 65+-5 | 65+-5 | / |

Brittle Point | Approx -35 | Approx -45 | Approx -45 | Degress C |

Falling Ball Test | -20 No Break | -40 No Break | -50 No Break | Degress C |

Flexibility | -20 No Break | -40 Bo Break | -50 No Break | Degress C |

Water Absorption | 0.20% | 0.20% | 0.20% | % |

Tensile Stress | 340 | 420 | 420 | % |

Rupture Resistance | >5 | >2 | >2 | N/mm |

Reaction to fire | Self-Extinguishing | Self-Extinguishing | Self-Extinguishing | 0 |

Flammability | Inflammable | Inflammable | Inflammable | 0 |

Airborne Insulation | ~35dB | ~35dB | ~35dB | 0 |

Light Transmission | >80 | >80 | >80 |

- Q:How does the flexural strength of plastic used in home appliances affect their resistance to bending or deformation?

- The flexural strength of plastic used in home appliances directly affects their resistance to bending or deformation. Higher flexural strength indicates that the plastic can withstand greater forces without bending or deforming. This means that home appliances with higher flexural strength plastics are less likely to break or distort under normal usage conditions, making them more durable and reliable.

- Q:What glue can glue PP plastic?

- Adhesion, align the PP plastic bonding parts to the titanium alloy and direct bonding without any external force. Note: if the material is heavier, the material will be assisted or positioned to prevent deformation of the joint due to gravity. Hope to help you.

- Q:Can plastic parts in home appliances be affected by electromagnetic radiation?

- Yes, plastic parts in home appliances can be affected by electromagnetic radiation. Electromagnetic radiation can cause heating, electrical discharge, and degradation of the plastic material, potentially leading to malfunction or damage of the appliance.

- Q:What are the typical thicknesses of home appliance plastics?

- The typical thicknesses of home appliance plastics can vary depending on the specific appliance and its components. However, in general, they range from around 1-3 millimeters for smaller parts like buttons or knobs to 4-6 millimeters for larger components such as panels or housings.

- Q:Plastic buckle and wood stick, what kind of glue?

- If nails are fixed, use structural adhesive or glass adhesive. If you can't fix it with nails, you must use fast viscose.

- Q:Can plastic home appliances be easily repaired in case of damage?

- No, plastic home appliances are not easily repaired in case of damage as plastic components are often difficult to fix due to their complex design and structure. Additionally, plastic is prone to cracking or breaking, making it more challenging to repair compared to other materials like metal. In most cases, it is more cost-effective to replace the entire appliance rather than attempting to repair plastic parts.

- Q:How do home appliance plastics impact the overall cost of the appliance?

- Home appliance plastics play a significant role in determining the overall cost of the appliance. By using plastic components, manufacturers can reduce production expenses and lower the overall cost of the appliance. Additionally, plastic materials offer versatility, allowing for various design options and cost-effective manufacturing processes. However, the choice of plastics can also influence the durability and quality of the appliance, which can impact the long-term maintenance cost and customer satisfaction.

- Q:How does plastic affect the ease of transportation for home appliances?

- Plastic has greatly improved the ease of transportation for home appliances due to its lightweight nature and durability. This allows for easier handling and reduces the risk of damage during transportation. Additionally, plastic packaging provides a protective layer, preventing scratches or dents on appliances, making their transportation more convenient and efficient.

- Q:Are there any specific guidelines for using home appliances with plastic parts in humid environments?

- Yes, there are specific guidelines for using home appliances with plastic parts in humid environments. It is recommended to keep the appliances in well-ventilated areas to prevent the accumulation of moisture. Regular cleaning and maintenance of plastic parts are also important to avoid mold or mildew growth. Additionally, using dehumidifiers or moisture-absorbing products can help control humidity levels and protect the longevity of the appliances.

- Q:Are there any specific guidelines for using home appliances with plastic parts in environments with high electromagnetic interference?

- Yes, there are specific guidelines for using home appliances with plastic parts in environments with high electromagnetic interference. It is recommended to ensure that the appliances have proper electromagnetic compatibility (EMC) certification, which guarantees their ability to withstand and function effectively in such environments. Additionally, it is advisable to minimize the distance between the appliance and potential sources of electromagnetic interference, such as power lines or radio equipment, to reduce the risk of malfunction or damage.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Anti Static PVC Strip Curtains in Green Color

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords