Amino Trimethylene Phosphonic Acid SGS Test

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

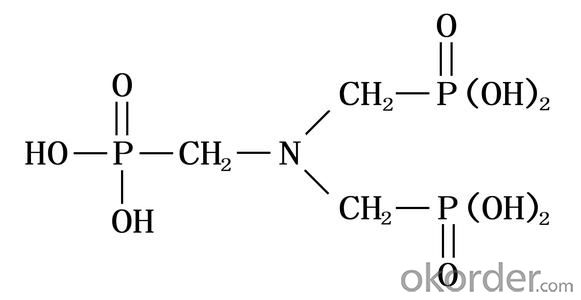

Amino tris(methylene phosphonic acid) / Amino Trimethylene Phosphonic Acid/ ATMP / 6419-19-8 / C3H12NO9P3

CAS No. 6419-19-8

Molecular Formula: N(CH2PO3H2)3

Molecular weight: 299.05

Structural Formula:

Properties:

ATMP has excellent chelation, low threshold inhibition and lattice distortion ability. It can prevent scale formation, calcium carbonate in particular, in water system. ATMP has good chemical stability and is hard to be hydrolyzed in water system. At high concentration, it has good corrosion inhibition.

ATMP is used in industrial circulating cool water system and oilfield water pipeline in fields of thermal power plant and oil refinery plant. ATMP can decrease scale formation and inhibit corrosion of metal equipment and pipeline. ATMP can be used as chelating agent in woven and dyeing industries and as metal surface treatment agent.

The solid state of ATMP is crystal powder, soluble in water, easily deliquescence, suitable for usage in winter and freezing districts. Because of its high purity, it can be used in woven & dyeing industries and as metal surface treatment agent.

Specification:

| Items | Index | |

|---|---|---|

| Standard | Solid | |

| Appearance | Clear, Colorless to pale yellow aqueous solution | White crystal powder |

| Active acid % | 50.0-51.0 | 95.0min |

| Chloride (as Cl-)% | 1.0 max | 1.0 max |

| pH value (1% solution) | 2.0 max | 2.0 max |

| Fe,mg/L | 10.0max | 20.0max |

| Density (20°C)g/cm3 | 1.31-1.35 | - |

| Colour APHA (Hazen) | 30.0max | - |

Application range&using method:

ATMP is usually used together with other organophosphoric acid, polycarboxylic acid and salt to built all organic alkaline water treatment agent. ATMP can be used in many different circulating cool water system. The recommended dosage is 5-20mg/L. As corrosion inhibitor, The recommended dosage is 20-80mg/L.

Package and Storage:

ATMP liquid: Normally In 30kg or 250kg net Plastic Drum;ATMP solid: 25kg inner liner polyethylene (PE) bag, outer plastic woven bag, or confirmed by clients request.Storage for ten months in room shady and dry place.

Safety Protection:

ATMP is Acidity, Avoid contact with eye and skin, once contacted, flush with water.

Shipping Date: Within 7-10 workdays after receiving your deposit.

Our Service:

Own Lab and joint venture factory.

Superb r&d team;Safety standardization production.

Rich experience in export and strong logistical support.

Good relationship with many large domestic pharmaceutical factory.

Perfect service, perfect supply chain.

- Q:Carbon dioxide and hydrogen in the catalyst and heating conditions, the reaction of water and methane, the chemical equation is what

- CO2 + 4H2 = catalyst, heating = 2H2O + CH4

- Q:What is the standard for the storage of flammable and explosive chemicals now?

- First, the basic requirements of classification of storage Dangerous goods, variety, complex performance, storage, in accordance with the zoning, classification, sub-section of the principle of special storage, set the number, set the number of fixed warehouses, fixed staff (four) custody. Small warehouses should be classified, divided, sub-stack storage, the performance of each other, fire fighting different items, dangerous dangerous goods and other general dangerous goods, should be stored separately.

- Q:The future direction of employment how, in what kind of units to do what work, how the closure rate? The

- Generally in the chemical plant to do engineering design engineers, the past few years, science and engineering graduates generally do not worry about work.

- Q:how could scientists know the exact catalyst for every reactions??? THANX sooo much

- Believe me, nema, there's no way that we chemists know the best catalyst for every reaction. That would be simply impossible. However, from the type of reaction, the reactants, products, reaction conditions, solvents, etc. and from one's experience and the literature (papers and patents) one can get a good idea for most reactions of the type of catalyst that has worked for similar systems. One then starts off with a catalyst from the literature and modifies or changes it if improvement is needed based on chemical principles that one learns. There are also some theoretical calculations that can be made. Sometimes they work and sometimes they don't :) If it is an industrially important process like the Haber process for making ammonia from nitrogen gas and hydrogen gas, there may be thousands of catalysts which have been tried and evaluated. New minor improvements are being made every day. When a company does find a very good catalyst for an important reaction, often they keep it a trade secret. The good catalyst can make a huge difference in how commercially successful a particular process is. That's a large part of what chemical engineers do. You may never know if you have the best catalyst. The most you can hope for is one that is good enough. So it's a few parts personal knowledge, a few parts literature, a couple of parts theory, a lot of experimentation and often, more than not, a little luck. :)

- Q:Chemical reaction in the presence of catalyst for the reaction are carried out a high life

- Some reactions require some of the catalyst that is not needed

- Q:Horseradish enzyme catalyzed Luminol chemiluminescence reaction

- Disinfectant ah ~ bleach ah ~ ~ take this kind of thing to wash the blood once something can interfere with Lumino identification. So that want to do bad things must be a good plan. Lumino in the presence of copper, copper alloy, horseradish or some bleach in the presence of fluorescence. So if the scene of the crime was bleached

- Q:What is the difference between biological and chemical catalysts?

- Biological catalysis involves an enzyme usually working in conjunction with a co-enzyme. These enzyme/co-enzyme systems are highly specific and are usually only effective for one reaction. Catalysis of non biological reactions is usually much more general and any one catalyst will be effective in many reactions.

- Q:In the chemical reaction will have to use the catalyst reaction, such as H2O2 === (MnO2) H2O + O2 ↑, then the catalyst in the end to participate in the reaction (that is, the catalyst itself is the reactant) If so, why are some of these substances in the reaction (these substances refer to the catalyst) in the reaction after the quality and nature of the change does not change?

- The definition of a chemical reaction rate in a chemical reaction can be changed (accelerated or slowed down) in a chemical reaction, and the quality and chemical properties of the substance itself are not catalyzed before and after the reaction (which will change during the reaction) Also known as catalyst. Its physical properties may change, for example, MnO2 in the catalytic potassium chlorate to generate potassium chloride and oxygen before and after the reaction from the block into a powder. There is also a saying that the catalyst reacts first with one of the reactants and then the two products continue to undergo a new chemical reaction under the original conditions and the reaction conditions of the catalyst reaction product are more favorable than the reaction conditions of the original reactants Changed.

- Q:Thorough explanation pls.

- A catalyst is a substance that increases the rate of a chemical reaction.

- Q:describe a biological catalyst?

- Enzyme are biological catalyst, proteinous in nature, formed in animal's body by exocrine cell, present in inactive form, generally ends with suffix ase e.g enterikinase with exceptions pepsin, specific in nature not only speed up biological reactions but also lower down the reactions inside the body.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Amino Trimethylene Phosphonic Acid SGS Test

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords