Aluminum Ingots AA1070

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

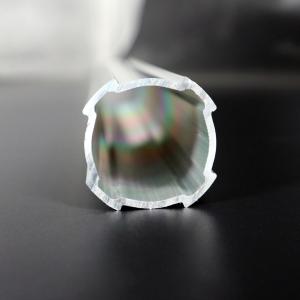

1. Specifications of Aluminum Ingots AA1070

Product Name | Aluminum Ingot |

Chemical Composition | Al |

Weight | 20/25kg |

Al (Min) | 99%-99.9% |

Appearance | silvery white |

Advantages | easy control and operation, fast melting |

Chemical Composition of Aluminum Ingots AA1070:

Grade | Chemical Composition % | |||||||||

Al≥ | impurities ≤ | |||||||||

Si | Fe | Cu | Ga | Mg | Zn | Mn | others | Sum | ||

Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 | - | 0.010 | 0.10 |

Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 | - | 0.015 | 0.15 |

Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 | - | 0.030 | 0.30 |

Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 | - | 0.030 | 0.40 |

Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.030 | 0.50 |

Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.050 | 1.00 |

2. Usage/Application of Aluminum Ingots AA1070

1. mainly used for melting ingot

2. discontinuous melting with scrap

3. easy control and operation

4. fast melting

5. Used for industry such as automobile,pinning and weaving,electron broadly and so on

3.Packaging & Delivery of Aluminum Ingots AA1070

About 25Kg /Ingot, Packed in wooden case, Net weight 1000Kg/ Case, or as customer's requirements.

(1)Standard seaworthy export packing, wooden pallets with plastics protection for the coil and sheet. (2)15-20MT can be loaded into 20 foot container, we try to use 20 foot container, and the sea freight rate is much cheaper than 40 foot container. (3) The other packing can be made based on the customer requirement. (4) The packing is very strong, which has 3 lays, thick fiber, and foam, plastic. The bottom is wooden pallets

- Q:What is the impact of alloying elements on the properties of aluminum ingots?

- Alloying elements have a significant impact on the properties of aluminum ingots. By adding certain elements, such as copper, magnesium, or silicon, to aluminum, the resulting alloy can exhibit improved strength, hardness, corrosion resistance, and thermal conductivity. These alloying elements can also enhance the casting, machining, and welding characteristics of aluminum ingots, making them more versatile and suitable for a wide range of applications in industries like aerospace, automotive, and construction.

- Q:How can I make aluminium ingots for cans?

- You need a basic open hearth is heating aluminum cans, but is not the direct melting aluminum ingot what meaning, that thing in a lot of impurities, but also remove the magnesium, zinc, manganese and other elements, these processes need professional personnel, so difficult to master.

- Q:Can aluminum ingots corrode?

- Yes, aluminum ingots can corrode.

- Q:How are aluminum ingots used in construction?

- Due to their exceptional properties and versatility, aluminum ingots are extensively utilized in the construction industry for various purposes. One of the common applications in construction involves using aluminum ingots to manufacture structural components like beams, columns, and trusses. The lightweight characteristic of aluminum makes it an ideal option for such uses, resulting in cost savings during transportation and installation due to reduced overall weight. Moreover, aluminum ingots are employed in the creation of cladding systems that cover the exterior of buildings. These cladding systems enhance the structure's visual appeal while providing protection against weather conditions and insulation benefits. The corrosion resistance and durability of aluminum make it the preferred material for cladding, enabling it to withstand harsh weather conditions and maintain its appearance over a prolonged period. Additionally, aluminum ingots are utilized in the fabrication of windows, doors, and curtain walls in construction projects. Aluminum frames offer both strength and stability, along with a sleek and modern aesthetic. The material's resistance to corrosion guarantees the longevity and low-maintenance nature of these components. Furthermore, aluminum ingots find applications in roofing systems. Aluminum roofs are highly corrosion-resistant, lightweight, and durable. Additionally, their high reflectivity reduces heat absorption and energy consumption, making them a sustainable choice for building projects. In conclusion, aluminum ingots play a vital role in the construction industry. Their lightweight nature, corrosion resistance, and durability make them an excellent choice for structural components, cladding systems, windows, doors, curtain walls, and roofing systems. The use of aluminum ingots not only enhances the overall aesthetics of a building but also contributes to its longevity, energy efficiency, and sustainability.

- Q:What kind of material is die casting aluminium ingot?

- Product (Unwrought). Products obtained by smelting (or refining) and casting. For example, rolled ingots, extruded ingots, wrought ingots, and remelting ingots

- Q:What is the melting point of aluminum ingots?

- Aluminum ingots typically reach a melting point of around 660 degrees Celsius, equivalent to 1220 degrees Fahrenheit.

- Q:What are the different cutting techniques for aluminum ingots?

- There are several different cutting techniques for aluminum ingots, including bandsaw cutting, plasma cutting, laser cutting, and waterjet cutting. Each technique offers its own advantages and is chosen based on factors such as the desired precision, speed, and cost-effectiveness of the cutting process.

- Q:What is the average weight of an aluminum ingot?

- The average weight of an aluminum ingot varies depending on its size and shape. However, a common average weight for an aluminum ingot is around 25 to 30 pounds (11 to 14 kilograms).

- Q:How are aluminum ingots used in the production of sporting goods?

- Aluminum ingots are widely used in the production of sporting goods due to their unique properties and advantages. Firstly, aluminum ingots are lightweight yet durable, making them an ideal material for manufacturing sports equipment such as baseball bats, tennis rackets, and golf clubs. The lightweight nature of aluminum allows for increased swing speed and maneuverability, enhancing the performance of athletes in these sports. Furthermore, aluminum ingots are corrosion resistant, ensuring that sporting goods made from aluminum can withstand exposure to moisture and other harsh environments. This property is particularly beneficial for sporting goods used outdoors, such as bicycles, camping equipment, and fishing rods. The corrosion resistance of aluminum ingots reduces the need for frequent maintenance and replacement, making them more cost-effective in the long run. Additionally, aluminum ingots can be easily molded and shaped into various designs, enabling manufacturers to create innovative and ergonomic sporting goods. For example, aluminum ingots are commonly used in the production of bicycle frames and components, allowing for customized designs that enhance stability, aerodynamics, and overall performance. Moreover, aluminum ingots possess excellent heat conductivity, making them suitable for the production of sports equipment that requires efficient heat dissipation. This includes skis and snowboards, where aluminum cores are used to regulate temperature and provide optimal flexibility and control on the slopes. In summary, aluminum ingots play a vital role in the production of sporting goods by offering lightweight, durable, corrosion-resistant, and easily moldable properties. These characteristics enable manufacturers to create high-performance, long-lasting, and innovative sporting equipment across a wide range of sports and outdoor activities.

- Q:What are the different methods for machining aluminum ingots?

- There are several different methods for machining aluminum ingots, including CNC milling, turning, drilling, grinding, and sawing. These methods allow for the precise shaping, cutting, and finishing of aluminum ingots to create various components and products.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan,China |

| Year Established | 1993 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Ingots AA1070

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 Tons m.t.

- Supply Capability:

- 1000 Sets Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords