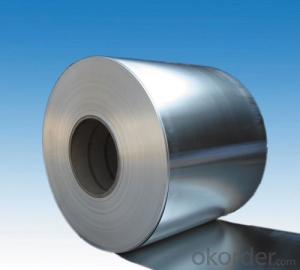

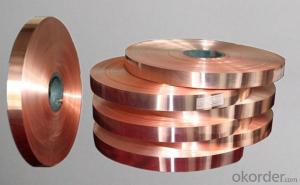

Aluminum Foil, Aluminum Foils, Aluminum Foil Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Specification of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1.Advantages of our Hot Rolled Checkered Steel Plate:

a) The unfairness of our checkered steel sheet must be less than 10mm each meter

b) The surface of our hot rolled checkered steel plate is free from bubble, scab, crack, fold, edge delamination and so on.

c) The height of our hot rolled checkered steel plate will be maintained between 0.2~0.3 times to thickness of steel substrate, but more than 0.5mm at least.

Applications of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1.Definition: The hot rolled steel sheet with raised pattern on surface. The raised pattern could be shaped as rhombus,bean or pea. There is not only one kind of pattern on the checkered steel sheet, but also a complex of two or more than two kinds of pattern on surface of one checkered steel sheet. It also could be called as grid steel sheet.

2.Character: The Hot Rolled Checkered Steel Plate possesses a variet of advantages, such as beauty in appearance,skip resistance and saving steel material.Generally speaking,in order to test the mechanical property or the quality of hot rolled checkered steel sheet, the shaping rate and the pattern height should be tested primarily.

3. In conclusion, the hot rolled checkered steel plate can usually be used in the industry of ship-building,boiler,automobil,tractor,train- building and architecture. In details, there are many demands for hot rolled checkered steel plate to make floor,ladder at workshop,work frame pedal,ship deck,car floor and so on.

Package & Delivery of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1. The items to be prepared for packing include: narrow steel strip, crude steel belt or edge angle steel, kraft paper or galvanized sheet.

2. The hot rolled checkered steel plate should be wrapped with kraft paper or galvanized sheet ouside, and it should be bundled with narrow steel strip, three or two narrow steel strip in longitudinal direction,and the other three or two strips in transverse direction. Furthermore, in order to fix the hot rolled checkered steel plate and avoid the strip at edge shall be broken, the crude steel belt cut into square should be put under the narrow steel strip on the edge. Of course, the hot rolled checkered steel plate could be bundled without kraft paper or galvanized sheet. It depends on customer’s requirement.

3. In consideration of the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4. All in all, we could do in accordance with customer's request.

Production Flow of Aluminum Foil, Aluminum Foils, Aluminum Foil-paper from China:

1.The steel raw materials are first melted in an electric furnace. They are subjected to at least 12 hours of intense heat.

2.The mixture is cast into either large rectangular blooms, slabs or bar-like billets, before taking on a semisolid form.

This initial form of steel is then processed via forming operations that include hot rolling into bars, wires, plates and slabs.

3.The steel is subjected to annealing. This is a heat treatment in which the metal is first heated and then cooled under extreme, controlled conditions. The metal is thus treated for internal stresses and is duly softened and strengthened. This processing is also referred to as 'age hardening'. It requires careful monitoring of temperature and heating and cooling times. The aging temperature affects metal properties massively; while lower temperatures cause high strength and low fracture toughness (i.e., more brittle than ductile), higher temperatures result in a tougher material of lower strength (i.e., more ductile than brittle). Rapid cooling can produce a tough steel with no significant loss in strength. The heat treatment given to stainless steel depends on the type and grade of steel being produced.

4. Annealing or the heat treatment can lead to the development of a precipitate, known as scale. The scale can be removed via several methods, such as pickling, (nitric-hydrofluoric acid bath),electrocleaning(application of an electric current, using phosphoric acid and a cathode), etc.

5. Descaling of the material is introduced into the manufacturing process at different times, depending on the type of steel being produced. While the bar and wire forms have to be additionally treated with hot rolling,forging and extruding, the sheet and strip forms go through annealing after hot rolling.

6. Cutting operations in the manufacturing process are essential in obtaining the desired shape and size of the end product. Mechanical cutting involves the use of guillotine knives and high-speed steel blades for blanking (punching out the shape by shearing) and nibbling (cutting out a series of overlapping holes). It is also cut via flame cutting, a process that involves the use of a flame generated by oxygen, propane and iron powder. The plasma jet cutting method uses an ionized gas column to melt and cut the metal.

6. Manufacturing end products involve further shaping via heat-rolling, pressing, forging and extrusion. The material is then joined via welding and given the desired shape.

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:my 2 year old put a big plastic bowl in my oven i didn't realize it until i put something in the oven too cook but it was too latethe bowl melted all down the grills and on the bottomI let it cool down and got the bottom off the plastic on the grills is still there it's hard and kinda stringywhat is the best way to get this plastic off any ideasthanks

- put a layer of aluminum foil in the bttom of the oven, put the racks in, heat the oven and after the racks are heated wear oven mitts and use a cheap throw away spatula from the dollar store to scrape the racks clean while they are in the oventhen take the foil out and throw it away

- Q:would you make a toilet paper dress for your wedding?

- I was leaning towards foil paperShiny aluminum should catch everyone's attention right?

- Q:I have been looking at crafts that use old chip bags to make new things out of (bags, purses, wallets.) Pretty much all the ones I have looked at have a laminated look to them and also in the instructions at some point they say to laminate the old bagsHow is this done? Do you have to bring them to some store or shop and have someone else do it for you or is there a way you can do it at home? Thanks!

- Depending on where you go, if it's in black bear country, or even someplace with some pesty critters, it's nice to bring a dog, if you have oneEven a little onemy little 7lb dog chased of a rather large black bear in kings canyonBears are thieves, they're always after your goodiesBe sure to not to keep food or other scented items in your tent or in your vehicleKeep it in the proper storage locker, or hang it high in a tree, away from you.

- Q:I make a HUGE batch of mash potato and tried making it creamy but it came out too waterySo I put like a lot of corn starch to make it sticker but the taste left a powdery after taste and texture was still a little weirdSo I tried frying it like a potato croquette but cuz it was too watery I could not roll it into a ball to dip it in flour and eggSo I just add oil to fry it but it didn't harden like a potato croquette or a thin crispy disc like I expectIt just became cooked mash potatoAlthough the powdery after taste disappeared and taste nice, it became sticky ( I think its because of the corn starch)Is there anyway to save it??? Because I made a huge batch and don't wanna waste it.

- Using an electric standing or hand mixer beat in a little more milk and melted or softened butterReheat and keep warm in a double boiler until serving timeIf you don't have double boiler, just put them in a heat proof bowl covered with aluminum foil, place the bowl over gently simmering water and leave it there until serving timeCheck the pot of water to make sure the water hasn't cooked outNever add flour or corn starch to mashed potatoes unless you are making a recipe that calls for itIf mashed potatoes are too liquid, put into a pot over low heat and cook gently, stirring often until the liquid had evaporated and the potatoes have thickened upIf your potatoes are too dry just add more milk and butter, but do it bit by bit.

- Q:All I remember about the dessert was that it had fruit in the middle (the crust might have been bread, but I don't remember) and that they wrapped it in foil and placed it right into the fireIt was outstandingI know they offer the campfire irons but I would really like to make these again and wish I could remember moreAny help would be appreciated.

- Well, wellAfter 38 years of playing Boy Scout, I finally see a beautiful girl cooking on a open fireGreat! You can let your Imagination run wild with this one For the bread, you can use bread, cake mix, bisquick, or the best is pie crustYou can choose just about any pie filling you likeEven the ones sold in a canLayer it how ever you want and sprinkle a little sugar on itBut here is the secretYou must either spray your aluminum foil with something like Pam , coat it with butter, grease, Crisco, etcThen you have to make absolutely sure the seams of the foil are tightYou are trying to make a little pressure cookerLay directly on hot coalsNo flamesTime will depend on the thickness of the packet and the heat of the coalsAlso, you can cook great foil packages of foodLike hamburger, sliced potatoes, onion, peppers, chicken, pineapple, and again let your stomach be your guide for combinationsInstead of greasing the foil, put bout 2 tbspof water in the packet before you seal itIf you can get some Industrial Aluminum foil, or double your foil if using store bought, your results will be betterNo seal means burnt food.

- Q:I was assigned a project for chemistry that will be graded on accuracyI have come up w/ ideas as to what to use (insulating Styrofoam fiberglass, sawdust, aluminum foil, a Styrofoam cooler inside another cooler, etc.) but I need to know exactly how to construct the structure-the materials were expensive, so that’s why I want to know exactly how to do it so I don’t mess it up!I’m sure many people have done this experiment before-your help would be greatly appreciated!Thanks guys!!!!!!!!Here are the directions:You’re mission is to keep an ice cube from melting for 6 daysNO outside use of power or dry ice in a 'glass’ and/or sealed container will be permitted!!build a structure to house the ice cube for 6 days (may use any materials.)

- I hope this is it! HOLIDAY OATMEAL COOKIES 2 cflour 1 1/4 csugar 1 tspbaking powder 1/2 tspsoda 1 tspsalt 1 tspcinnamon 1 craisins or candied fruit 3 crolled oats 1/2 cchopped nuts 1 cMazola corn oil 2 eggs 1/2 cmilk Sift together dry ingredientsAdd rolled oats, raisins (or fruit) and nuts and mix thoroughlyAdd in order Mazola oil, eggs, milkStir until thoroughly blendedDrop by teaspoons on ungreased baking sheetsHot oven - 400 degrees for 10-12 minutesMakes 6 dozen or try HOLIDAY OATMEAL CHOCOLATE CHIP COOKIES 1 cbutter flavor Crisco 1 cfirmly packed brown sugar 1/2 cgranulated sugar 2 eggs 2 tbspmilk 2 tspvanilla 2 1/2 cQuaker oats (quick or old fashioned, uncooked) 1 1/2 call purpose flour 1 tspbaking soda 1/2 tspsalt (optional) 1 csemi-sweet chocolate pieces 1 choliday candy coated chocolate pieces or colored chips 1 ccoarsely chopped nuts Heat oven to 350 degreesBeat firs 6 ingredients until smoothAdd combined oats, flour, soda, and salt; mix wellStir in remaining ingredientsDrop by rounded tablespoonfuls 3 inches apart onto ungreased cookie sheetBake 8-10 minutes for chewy or 10-12 minutes for crisp cookiesCool 2 minutes; remove to wire rackCool completelyAbout 4 dozen ENJOY

- Q:I had this delicious pastry yesterdayIt was like a pie crust the size of a small bowl and it had a vanilla pudding/custard like fillingThen it was topped with a gel of some sort and fresh fruit (The gel might have been the fruit juices meeting with the custard/pudding I am not sure) I would really like to know what it is so I can find a recipe and make it for when my in laws come over :-)

- the silicone pans would be perfect for the breads! metal pans tend to burn and cook unevenly, but the silicone turns out a perfect golden result, and the bread will simply fall right out of the pan! Plus, clean up is a breeze, cuz nothing sticks or stains the siliconei can't live without mine! don't get her just the loaf pans, get her an entire set of silicone bakeware!! they got a decent set at walmart and target for about $30-$35well worth it!!

- Q:What equipments are needed to produce aluminum foil bag?

- It depends on whether you directly use composite aluminum foil film or raw materials that aren't well composited. If you directly use composite aluminum foil film, you may need dividing and cutting machine and bag machine. If you use raw material,you may need printing press, compound machine,dividing and cutting machine and bag machine.

- Q:a) household smoke alarms b) radiotherapy for cancer patients c) monitoring thickness of aluminium foil being made as a continuous sheetHow does each use depend on the penetrating ability of radiation?

- My brother is a truck driver and i also wanna be a Truck driver.

- Q:1: cabinets do not need the top ~? :2: cabinet 16mm good or 18mm good ~?3: why is the price of quartz stone so big?4: which ones should be selected in foil paper and ABS?

- The best of the foil, aluminum foil with adhesive, internal seamless fit the entire cabinetThe cabinet needs a roof to ensure the safety of the tableOn the basis of the same plate, the thickness is better, if the thickness of the sheet is different, there is no comparabilityQuartz stone is divided into many different materials, but also cast and pressed the two approach, product quality varies greatly, the inferior quartz stone will be bleeding, easy to break, in fact, artificial stone is the same, bleeding is inferior man-made stone, as long as 100 meters, high-quality full aluminum artificial stone not bleeding that price is not cheaper than quartz stone

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Foil, Aluminum Foils, Aluminum Foil Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords