Aluminium Foil Aluminum Sheet for Bubble Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1. Structure of Aluminium Foil Description:

Aluminium Foil is structured by aluminium paper, which is the raw material .It is suitable for: Tobacco, food, beer, beverage, decoration, electric cable, electrolytic capacitor, medicine and air-conditioner.

2. Main Features of the Aluminium Foil:

High heat reflection & low thermal conductivity

Heat preservation & energy saving

Moisture barrier & waterproof

Low flammability

Strong, durable & corrosion resistance

Light weight & easy to install

Clean, safe and fibre free & no odour and toxicity, totally environmental-friendly

No mildew growth & no rodent and insect nesting

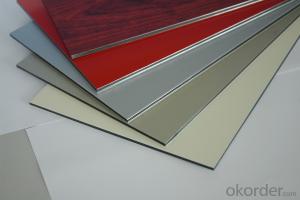

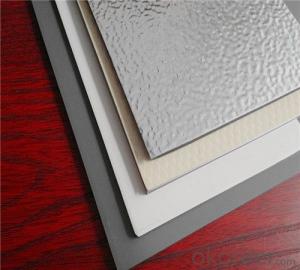

3. Aluminium Foil Images

4. Aluminium Foil Specification

1)Grade: 1050,1060,1070,1100,1200,1235,3003,3102,8011, 8079 etc.

2)Temper: O,H14,H18,H22,H24,H26

3)Thickness: 0.006mm-0.7mm, per customer’s request.

4)Width:15mm-1500mm

We produce the following 3 categories of products:

Aluminum Foil for Food--including food packaging and food container

Aluminum Foil for Packaging--wide application

Aluminum Foil for Industry--used in industrial processing

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How long can we receive the product after purchase?

The purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:That detailed point Oh, I want the detailed process, which know ah, tell me ah, thank you!

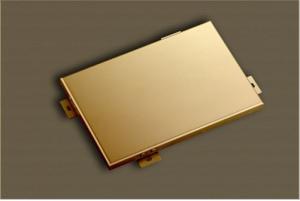

- Super weatherability Due to the use of KYNAR-500-based PVDF fluorocarbon paint, weatherability has a unique advantage, both in the hot sun or cold snow are not detrimental to its beautiful appearance, Up to 20 years does not fade.

- Q:OKorder Province, the price of aluminum-plastic plate market how? There is no sale of aluminum-plastic plate manufacturers can give a price list of aluminum-plastic plate

- OKorder side seems to have a lot of money in Kunming side of the purchase, you can go there to see the rain dragon, where there is a building city, do not know if you ask me

- Q:Dry hanging stone, aluminum-plastic board two kinds of external wall decoration use and maintenance costs, investment costs, the applicability of the two materials decorative effect construction speed

- In terms of construction speed, if the aluminum-plastic plate material can realize the factory construction, the assembly workshop assembly form, then the construction speed is obviously faster than the stone material.

- Q:Astella aluminum plate 3 plywood price how much ah?

- Such as 0.20 mm, 0.18 mm, 0.15 mm, 0.12 mm, 0.08 mm, 0.06 mm, etc., the price of each thickness is different, while the surface of aluminum 0.20 mm, aluminum 95; Price can be seen is not the same, therefore, generally asked, but can give a range of 80-180 yuan, should be the price.

- Q:Aluminum panels are used in what areas, can not be more detailed.

- Aluminum-plastic composite panel referred to as aluminum-plastic plate, is made by the surface treatment and coated with aluminum paint as the surface, polyethylene plastic plate as the core layer, after a series of process processing complex made of new materials.

- Q:Is the aluminum-plastic plate plastic? What is the difference between the two? What are their uses?

- They are the same building materials. 1, in normal weather conditions, the surface paint does not occur peeling, blistering, cracking, powdering phenomenon. 2, under normal environmental conditions, does not occur plate peeling, bubbling phenomenon. 3, when the plate exposed with normal radiation or temperature conditions, no abnormal color phenomenon. 4, according to the provisions of international inspection methods to check, the indicators have reached the national standards and corporate standards or contract requirements. 5, in accordance with the national standard aluminum-plastic composite panel GB / T17748-1999 production of fluorocarbon wall panels, coated with 70% fluorocarbon resin, in normal weather and environmental conditions, we can provide 10 to 15 years of quality assurance The Fireproof aluminum-plastic plate, in addition to the physical and mechanical properties of ordinary aluminum-plastic plate, but also has a good fire performance, the combustion performance meet or exceed the QB8624 requirements of the B1 level. The following conditions do not belong to the scope of warranty: A, non-normal use of the company's products, such as interior wall for the external walls. B, non-normal climate, temperature, temperature and other environmental conditions, the use of the company's products, such as in the vicinity of high-temperature boiler using aluminum-plastic plate, near the plate with acid and other corrosive gases. C, the use of the company under the conditions of the product, and the construction technology without effective technical measures, such as the installation of external wall panels using bonding method. D, storage during the poor environmental conditions, placement method error, brutal handling, resulting in sheet deformation, damage and so on. E, the damage of the plate is caused by mechanical damage, and damage signs are obvious when loading the plate condition, such as surface scratches and so on.

- Q:Jiqiu material for the aluminum-plastic plate, due to years of wind and rain, dust deposition and other reasons, resulting in the appearance of rust, stains appearance rust method can clean? The

- Material for the aluminum-plastic plate, due to years of wind and rain, dust deposition and other reasons, resulting in rust, stains serious, the use of water rinse and oxalic acid dilution solvent cleaning no effect

- Q:How to install the aluminum-plastic panel ceiling?

- The more common installation method is to directly through the self-tapping screws in the aluminum plate above the keel, so there will be nail caps, but can be secretly fight. This is relatively easy.

- Q:How to separate the aluminum alloy on the aluminum plate

- Are there any aluminum alloy on aluminum? If so, is also sticky, cut it! If the whole, or destroyed the aluminum-plastic plate, or destroyed the aluminum!

- Q:What is the difference between stretching aluminum and hot-rolled aluminum? What is the concept of stretching aluminum?

- Hot-rolled aluminum plate is the aluminum plate is the use of hot-rolled process produced by the aluminum plate, stretching aluminum is produced by the aluminum plate after stretching made of aluminum and aluminum parts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Foil Aluminum Sheet for Bubble Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords