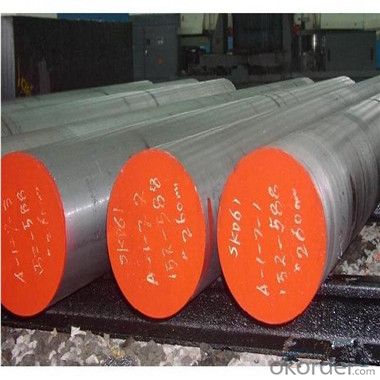

1010 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1010 Carbon Steel Round Bar

| Commodity | 1010 Carbon Steel Bar | |||||

| Standard | GB | JIS | ASTM | DIN | ISO | |

| 10F | SPHD,SPHE | 1010 | 1.033 | C10 | ||

| Chemical Composition | C | Si | Mn | P | S | Cr |

| 0.08~0.13 | 0.15~0.35 | 0.30~060 | ≤0.040 | ≤0.050 | ~~ | |

| Mo | Cu | Ti | Al | V | Pb | |

| ~~ | ~~ | ~~ | ~~ | ~~ | ~~ | |

| Size/Diameter | 4-240mm | |||||

| Length | 2-12m, as customers' request | |||||

| Surface | Black/Bright, or as customers' request | |||||

| Manufacture | Hot Rolled/Cold Drawn/Forged | |||||

| Packing | Packed in bundles with standard export sea-worthy package | |||||

| Delivery Time | Within 20 working days, according to customers' quantities | |||||

| Quality | High Quality, TUV inspection is accepted if needed | |||||

| Place of Origin | Tianjin | |||||

| Brand Name | TG | |||||

| Productivity | 500 MT/Month | |||||

| MOQ | 5 MT | |||||

| Application | Foodstuff, Gas, metallurgy, biology, electron, chemical etc. | |||||

| Note | We also can supply you all kinds of carbon steel goods as your order | |||||

Other Feature:

we have professional and strictly producing control system as below:

Before Formed : Assurance of compliance

Review of Sub-vendor ; quality plan ;

Review of samples certification (MTC)

Chemical analysis

Tension &Mechanical tests

Finished : MT testing for Edge (If Exist)

Visual examination

Thickness measurment (Continous Ultrasonic)

Lenght dimension control.

Straightness

Visual & Dimention check of edge

Weight control

Marking

Material & NDT retest (if required)

Ready for delivery : Protection coating

Certificate of compliance

Packing check

Shiping mark and number check

- Q:Are steel round bars suitable for the production of axles?

- Yes, steel round bars are suitable for the production of axles. Steel round bars are known for their high strength and durability, making them ideal for the heavy-duty requirements of axles. They can withstand the forces and stresses applied during operation, ensuring the axles can efficiently support and transmit the load. The round shape of the bars also allows for easy machining and forming into axles of various sizes and configurations.

- Q:What is the difference between a solid round bar and a hollow round bar?

- A cylindrical shape, known as a solid round bar, consists of a single material, typically metal or plastic. It maintains a consistent diameter throughout its length, without any empty space inside. In contrast, a hollow round bar also has a cylindrical shape but contains a hollow space within its center. This hollow space creates a tube-like structure within the bar. The outer diameter remains constant, but the inner diameter varies depending on the design and purpose of the hollow round bar. The primary distinction between a solid round bar and a hollow round bar lies in their structural characteristics and potential uses. The solid round bar offers strength and rigidity due to its solid core, making it suitable for applications requiring robust support or load-bearing capabilities. It finds common usage in construction, manufacturing, and engineering projects where strength and durability are vital. Conversely, the hollow round bar combines strength with a lightweight design. The presence of the hollow space reduces the overall weight while maintaining structural integrity. This makes hollow round bars ideal for applications prioritizing weight reduction, such as in the aerospace, automotive, and marine industries. Furthermore, the hollow space can serve various purposes, such as facilitating the passage of fluids, wires, or other components through the bar. In conclusion, while both solid and hollow round bars possess a cylindrical shape, the presence or absence of a hollow space distinguishes them. Solid round bars offer strength and rigidity, while hollow round bars strike a balance between strength and reduced weight, with the potential for additional functionality. The choice between the two depends on the specific requirements and intended application of the bar.

- Q:Can steel round bars be used in the manufacturing of tools?

- Yes, steel round bars can be used in the manufacturing of tools. Steel round bars are commonly used in tool manufacturing due to their high strength, durability, and versatility. They provide the necessary structural integrity and toughness required for various tools, such as wrenches, hammers, chisels, and screwdrivers. The round shape of the bar allows for easy machining and shaping into different tool components. Additionally, steel round bars can be heat treated to enhance their hardness and wear resistance, making them suitable for heavy-duty and high-performance tool applications.

- Q:What are the different surface finishes available for steel round bars?

- Steel round bars can be finished in various ways, each with its unique properties and applications. Some commonly used surface finishes include: 1. Hot Rolled: By heating the steel above its recrystallization temperature and allowing it to cool, a rough and scaled surface is achieved. This finish is suitable for applications that prioritize functionality over aesthetics. 2. Cold Drawn: The steel round bar is pulled through a die at room temperature, resulting in a smooth and polished surface. This finish offers improved dimensional accuracy and tight tolerances, making it ideal for precise applications that require a visually appealing appearance. 3. Turned and Polished: Using a lathe machine, the steel round bar is turned to achieve a smooth and shiny surface. This process eliminates any imperfections and irregularities, providing a close tolerance and highly finished surface. Turned and polished bars are commonly used in applications that demand high surface finish and dimensional accuracy, such as shafts and precision components. 4. Ground: Grinding is employed to remove surface defects and irregularities, resulting in a highly accurate and smooth surface finish. This finish is suitable for applications that require close tolerances and a superior surface finish, such as bearings, gears, and high-precision components. 5. Coated: Steel round bars can be coated with materials like zinc, chrome, or nickel to enhance their performance and protect against corrosion. Coated bars offer improved durability, corrosion resistance, and aesthetic appeal. The choice of surface finish for steel round bars depends on specific application requirements, including dimensional accuracy, surface quality, corrosion resistance, and aesthetic appeal.

- Q:What is the difference between a bright and a cold finished steel round bar?

- A bright steel round bar refers to a steel bar that has undergone a process called bright drawing, which involves passing the bar through a series of dies to achieve a smooth and shiny surface finish. On the other hand, a cold finished steel round bar is produced by cold drawing, which involves pulling the bar through a die to reduce its diameter and improve its dimensional accuracy. The cold finishing process does not result in a bright and shiny surface like bright drawing does, but it enhances the mechanical properties and overall quality of the bar.

- Q:What is the maximum length available for steel round bars?

- The maximum length available for steel round bars can vary depending on the supplier and the specific requirements, but typically it can range from 12 to 24 feet.

- Q:Can steel round bars be used in the aerospace manufacturing industry?

- Yes, steel round bars can be used in the aerospace manufacturing industry. Steel is a commonly used material in aerospace applications due to its strength, durability, and resistance to high temperatures. Steel round bars are often used in the construction of aircraft frames, landing gears, and engine components.

- Q:How do you measure the hardness of a steel round bar?

- The hardness of a steel round bar can be measured using various methods, with the most common method being the Rockwell hardness test. This test involves applying a specific load to an indenter and measuring the depth of the indentation left on the material's surface. To measure the hardness of a steel round bar using the Rockwell hardness test, the following steps can be followed: 1. Select the appropriate Rockwell scale for the steel being tested. The most commonly used scales for steel are HRC (Rockwell C) and HRB (Rockwell B). 2. Clean the surface of the steel round bar to remove any dirt, oil, or contaminants that could affect the accuracy of the test. 3. Place the steel round bar on a flat and stable surface, ensuring it is properly supported to prevent any movement during testing. 4. Select the appropriate indenter for the chosen Rockwell scale. For HRC, a diamond cone indenter is typically used, while for HRB, a hardened steel ball is used. 5. Apply a preliminary minor load to the indenter, typically 10 kgf (kilogram-force) for HRC and 3 kgf for HRB. This helps ensure proper contact between the indenter and the material's surface. 6. Apply the major load, which is specific to the chosen Rockwell scale. For HRC, it is typically 150 kgf, while for HRB, it is usually 100 kgf. 7. Allow the major load to dwell for a specific period, typically 15 seconds, to ensure proper indentation. 8. Release the major load while keeping the minor load applied. This allows the indenter to partially recover, reducing the depth of the indentation. 9. Measure the depth of the remaining indentation using a microscope or a specialized Rockwell hardness testing machine. The measured value corresponds to the hardness value on the chosen Rockwell scale. It is important to note that the Rockwell hardness test is just one of several methods available to measure the hardness of a steel round bar. Other methods, such as the Brinell hardness test or the Vickers hardness test, may also be used depending on the specific requirements of the application.

- Q:How are steel round bars used in the automotive industry?

- Due to their strength, durability, and versatility, steel round bars are commonly employed in the automotive industry for a range of purposes. The production of crankshafts is one of the primary uses of steel round bars in this industry. Crankshafts are essential in converting the reciprocating motion of pistons into rotational motion, which powers the vehicle. Steel round bars are highly suitable for this function due to their high tensile strength, exceptional fatigue resistance, and ability to endure high torque loads. Steel round bars are also utilized in the manufacture of axles. Axles play a critical role in transferring power from the engine to the wheels while supporting the vehicle's weight and ensuring stability. Steel round bars provide the necessary strength and rigidity to handle the substantial loads and forces experienced by axles. Furthermore, steel round bars are employed in the production of suspension components like tie rods and sway bars. Tie rods are crucial for steering and maintaining proper alignment, while sway bars help control body roll and enhance handling. Steel round bars are preferred for these applications due to their exceptional torsional strength, enabling them to withstand the forces and stresses encountered during steering and suspension movements. Moreover, steel round bars are used in the creation of transmission shafts. Transmission shafts are responsible for transmitting power from the engine to the wheels through the gearbox. Steel round bars are well-suited for this task due to their high strength, resistance to bending, and ability to handle the rotational forces and torque generated by the engine. In conclusion, steel round bars are extensively employed in the automotive industry for various applications including crankshafts, axles, suspension components, and transmission shafts. Their superior strength, durability, and versatility make them an ideal choice for these critical components, ensuring the safety, performance, and reliability of vehicles.

- Q:What are the different types of steel used for round bars?

- There are several different types of steel used for round bars, including carbon steel, alloy steel, stainless steel, and tool steel. Each type has its own unique composition and properties, making them suitable for various applications and industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1010 Carbon Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords