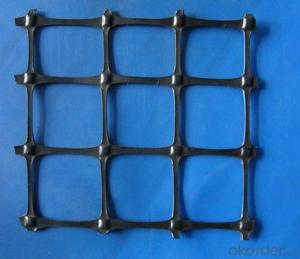

Triax 160

Triax 160 Related Searches

Tensar Triax 160 Geogrid Triax 160Hot Searches

Tensar Triax 160 Geogrid Price Tensar Triax 160 Geogrid Price Tensar Triax 160 Geogrid PriceTriax 160 Supplier & Manufacturer from China

Okorder.com is a professional Triax 160 supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Triax 160 firm in China.Hot Products

FAQ

- Yes, geogrids are suitable for use in slope stabilization for mining tailings dams. Geogrids provide reinforcement and stability to the slopes, preventing erosion and potential failure of the dam. They are designed to withstand high loads and are effective in controlling soil movement, making them an ideal solution for slope stabilization in mining tailings dams.

- Yes, geogrids are effective in preventing soil erosion around pipelines. Geogrids provide structural support and reinforcement to the soil, preventing it from eroding and destabilizing around the pipelines. They help distribute the load and reduce the potential for soil movement, ensuring the stability and longevity of the pipeline infrastructure.

- Yes, geogrids have proven to be effective in reducing pavement rutting. Geogrids are a type of reinforcement material that helps distribute the load from vehicles more evenly, reducing the pressure on the pavement surface. This prevents the formation of rutting and extends the lifespan of the pavement.

- There are several factors that can affect the cost-effectiveness of geogrid-reinforced structures. Firstly, the type and quality of the geogrid material used can significantly impact the overall cost. Higher-quality geogrids may initially be more expensive but offer better long-term performance, potentially reducing maintenance and repair costs over time. Additionally, the design and engineering of the structure play a crucial role. Properly designed geogrid-reinforced structures can optimize material usage and minimize construction costs. The expertise and experience of the engineers and contractors involved also contribute to the cost-effectiveness, as their knowledge can help avoid unnecessary expenses and ensure efficient construction. The specific site conditions, such as soil characteristics and slope stability, are also important factors. Geogrids are typically used to enhance soil stability, so the suitability of the soil for reinforcement and the extent of reinforcement required can impact costs. Difficult terrain, challenging access, or the need for additional site preparation can also increase costs. Lastly, the lifespan and durability of geogrid-reinforced structures should be considered. While geogrids are designed to be long-lasting, factors like environmental conditions, loading requirements, and proper installation can affect their performance. Investing in high-quality materials and proper installation methods may initially increase costs but can result in longer service life and reduced maintenance expenses in the long run.

- Yes, geogrids generally do not require any maintenance once they are properly installed. They are designed to be durable and resistant to environmental factors, reducing the need for regular maintenance.

- Yes, geogrids are suitable for reinforcement of airport runways. Geogrids are specifically designed to provide soil stabilization and increase load-bearing capacity, which is crucial for heavy aircraft traffic on runways. They effectively distribute the load, enhance the strength and stability of the runway subgrade, and minimize the potential for settlement or rutting. Moreover, geogrids are durable, resistant to environmental conditions, and can significantly extend the lifespan of airport runways.

- How much is the steel plastic geogrid?

- Steel plastic geogrid 50KN, 4.5 yuan per squareSteel plastic geogrid 60KN, 5 yuan per square

- What is high strength geogrid

- High strength geogrid.