Stainless Steel Can Koozie

Stainless Steel Can Koozie Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Used Solar Inverter For Sale Steel Mesh Panels For SaleStainless Steel Can Koozie Supplier & Manufacturer from China

Okorder.com is a professional Stainless Steel Can Koozie supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Stainless Steel Can Koozie firm in China.Hot Products

FAQ

- There are several advantages of using steel pipes over other materials like PVC or copper. Firstly, steel pipes have superior strength and durability, making them suitable for high-pressure applications and extreme weather conditions. Secondly, steel pipes have excellent corrosion resistance, ensuring a longer lifespan compared to PVC or copper. Additionally, steel pipes offer better fire resistance, making them safer for certain applications. Lastly, steel pipes have higher thermal conductivity, allowing for efficient heat transfer.

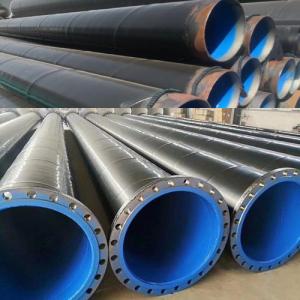

- Steel pipes are coated for protection through a process called corrosion protection coating. This typically involves applying a layer of epoxy, polyethylene, or other specialized coatings onto the surface of the steel pipes. The coating acts as a barrier, preventing direct contact between the steel and any corrosive substances in the environment, thereby extending the lifespan of the pipes and enhancing their durability.

- Steel pipes are commonly used in industrial manufacturing processes for various purposes such as transporting fluids, gases, and solids, as well as providing structural support. They are used in industries like oil and gas, construction, automotive, and chemical manufacturing. Steel pipes offer high durability, strength, and resistance to corrosion, making them ideal for handling harsh environments and high-pressure applications. Additionally, they can be easily welded, bent, and manipulated to fit specific requirements, allowing for efficient and cost-effective installations.

- Quality control measures for steel pipe production typically involve various inspections and tests at different stages of the manufacturing process. Some of the key measures include: 1. Raw material inspection: Ensuring that the steel used for pipe production meets specified standards for chemical composition, mechanical properties, and dimensional accuracy. 2. Dimensional inspection: Checking the outer diameter, wall thickness, and length of the pipes to ensure they meet the required specifications. 3. Welding inspection: Verifying the quality of welds by conducting non-destructive tests, such as ultrasonic or radiographic testing, to detect any defects or discontinuities. 4. Surface inspection: Examining the pipe surface for any defects, such as scratches, pits, or corrosion, which can affect the overall quality and performance. 5. Mechanical testing: Performing tests like tensile strength, yield strength, and impact resistance to assess the mechanical properties of the pipes and ensure they meet the desired standards. 6. Pressure testing: Subjecting the pipes to hydrostatic or pneumatic pressure tests to verify their ability to withstand the intended operational pressures without leakage or failure. 7. Coating inspection: Checking the quality and uniformity of any protective coatings or linings applied to the pipes to prevent corrosion or other forms of deterioration. 8. Documentation and traceability: Maintaining records of all inspections, tests, and certifications to provide traceability and ensure compliance with relevant industry standards and customer requirements. These quality control measures help to ensure that steel pipes are manufactured to the highest standards, possess the required mechanical and dimensional properties, and are fit for their intended application.

- Steel pipes are suitable for use in extreme weather conditions because they are known for their high strength and durability. This makes them applicable in construction, infrastructure, and transportation. Steel pipes are commonly used to transport fluids and gases across industries and are specifically designed to withstand harsh environmental conditions such as extreme temperatures, high pressures, and corrosive environments. Even in extreme weather conditions like intense heat, cold, or heavy rain, steel pipes can maintain their structural integrity and functionality. Moreover, they can be coated or insulated to provide extra protection against corrosion and maintain desired temperatures. In conclusion, steel pipes are a dependable option for extreme weather conditions due to their strength, durability, and ability to resist various environmental factors.

- The buoyancy of steel pipes in water can be calculated by determining the weight of the water displaced by the submerged portion of the pipe. This can be done by multiplying the volume of the submerged portion of the pipe by the density of water. The buoyant force acting on the pipe can then be calculated by multiplying the weight of the displaced water by the acceleration due to gravity.

- Yes, steel pipes can be used for underground stormwater drainage. Steel pipes are commonly used in underground drainage systems due to their durability, strength, and resistance to corrosion. They can effectively manage the flow of stormwater and provide long-lasting solutions for underground drainage needs.

- One way to protect steel pipes from fire is by applying a fire-resistant coating or insulation. This can help prevent the pipes from reaching the critical temperature where structural integrity is compromised. Additionally, installing fire rated enclosures or barriers around the pipes can provide an extra layer of protection. Regular inspections and maintenance are also crucial to ensure any potential fire hazards are identified and addressed promptly.