Hot Rolled Steel Plate

Hot Rolled Steel Plate Related Searches

Best Paint For Stainless Steel Blanket Insulation For Steel Buildings Primer For Galvanized Steel Foam Filter For Stainless Steel H S Code For Stainless Steel Surface Grinding Wheels For Stainless Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For BbqHot Searches

Steel Mesh Panels For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Price Of Shipping Containers For Sale Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Aluminum Coil Stock For Sale Large Led Screens For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For SaleHot Rolled Steel Plate Supplier & Manufacturer from China

Okorder.com is a professional Hot Rolled Steel Plate supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Hot Rolled Steel Plate firm in China.Hot Products

FAQ

- Steel sheets have excellent vibration resistance due to their high stiffness and density. The rigidity of steel enables it to dampen vibrations effectively, making it a reliable choice for applications where vibration control is crucial.

- Indeed, a variety of colors are accessible when it comes to steel sheets. To cater to specific aesthetic or design inclinations, steel sheets can undergo coating or painting processes in diverse shades. The available color selections may differ depending on the manufacturer or supplier, although popular options encompass black, white, gray, blue, red, and green. Furthermore, certain steel sheets may possess a textured or patterned finish that amplifies their visual allure.

- Yes, steel sheets are suitable for outdoor sculptures. Steel has high durability, strength, and resistance to weathering, making it an ideal material for withstanding outdoor conditions. Additionally, steel can be easily manipulated and shaped, allowing for intricate and creative sculptures to be crafted.

- A smooth stainless steel sheet is one that possesses a uniform and flat surface, devoid of any visible texture or patterns. It finds its typical usage in scenarios where a sleek and polished appearance is sought after, like in architectural designs or decorative elements. In contrast, a perforated stainless steel sheet is characterized by the presence of small or large holes that have been punched or drilled into it, resulting in an arrangement of openings on its surface. These openings can take various shapes, such as round, square, or any other, depending on the desired aesthetic or functional requirements. Perforated sheets are commonly employed in situations where ventilation, filtration, or visibility is necessary, such as in industrial equipment, acoustic panels, or safety grating. The primary distinction between a smooth and perforated stainless steel sheet lies in the presence or absence of holes on the surface. While a smooth sheet offers a pristine and uninterrupted appearance, a perforated sheet offers several advantages, including improved airflow, enhanced visibility, and increased sound absorption. Furthermore, the choice between a smooth or perforated sheet hinges on the specific application and the desired functionality. Smooth sheets are ideal for situations that call for a seamless and polished look, while perforated sheets are well-suited for applications that necessitate functionality, such as filtering, screening, or facilitating airflow.

- Steel sheets are generally known for their high tensile strength and stiffness, making them resistant to warping or bending. They are highly durable and can withstand heavy loads without deforming. However, it is important to consider that the thickness and quality of the steel sheet can affect its resistance to warping or bending. Thicker steel sheets tend to be more resistant compared to thinner ones. Additionally, factors like temperature changes and improper handling or installation can also impact the ability of steel sheets to resist warping or bending. Despite these factors, steel sheets are widely used in various industries due to their exceptional resistance to warping or bending.

- The environmental impacts of steel sheet production include carbon emissions, air pollution, water pollution, and the depletion of natural resources. The process of extracting iron ore and refining it into steel requires large amounts of energy, often generated from fossil fuels, leading to significant carbon dioxide emissions. The emissions contribute to climate change and air pollution, impacting human health and the environment. The production process also generates air pollutants such as sulfur dioxide and nitrogen oxides. Additionally, steel production involves the use of chemicals that can contaminate water sources, posing risks to aquatic ecosystems and human consumption. Moreover, the extraction of iron ore and other raw materials for steel production contributes to habitat destruction and the depletion of natural resources.

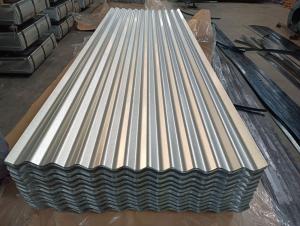

- Steel sheets are made through a process called hot rolling, where steel ingots are heated and passed through a series of rolling mills to reduce their thickness and shape them into flat sheets.

- Steel sheets are not typically used for thermal insulation purposes, as steel is a good conductor of heat. This means that it easily transfers heat from one side to the other, making it unsuitable for insulating against thermal energy transfer. In fact, steel sheets can even act as a thermal bridge, allowing heat to flow through them and bypass any insulation that may be present. To achieve effective thermal insulation, materials with low thermal conductivity, such as insulation foams or fiberglass, are commonly used instead. These materials are designed to minimize the transfer of heat and provide better insulation performance.