Form Work Concrete

Form Work Concrete Related Searches

Off Form Concrete Ready Mix Concrete Edmonton Concrete Driveway Coatings Resurface Concrete Driveway D Form Bar Aluma Beam Capacity Rear Bumper Beam Kanye West Ultralight Beam Snl Ultralight Beam Kanye West Snl Ultralight Beam Kanye SnlHot Searches

Quick Form Scaffolding For Sale Quick Form Scaffolding For Sale Quick Form Scaffolding For SaleForm Work Concrete Supplier & Manufacturer from China

Okorder.com is a professional Form Work Concrete supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Form Work Concrete firm in China.Hot Products

FAQ

- Steel formwork differs from other types of formwork in several ways. Firstly, steel formwork is highly durable and can be used multiple times, whereas other types of formwork such as wood or plywood may need to be replaced after a few uses. Additionally, steel formwork provides a smooth and precise finish, resulting in high-quality concrete structures. It also offers a higher load-bearing capacity, allowing for the construction of larger and more complex structures. Moreover, steel formwork can be easily fabricated and assembled, reducing construction time and labor costs. Overall, steel formwork is a more robust, efficient, and cost-effective solution compared to other types of formwork.

- Yes, steel formwork can be used for industrial flooring. Steel formwork is a durable and strong option for creating concrete slabs that are commonly used in industrial flooring applications. It provides stability, precision, and can withstand the heavy loads and frequent traffic associated with industrial environments.

- Yes, there are several specific considerations for using steel formwork in areas with high seismic activity. Firstly, the steel formwork needs to be designed and constructed to withstand the seismic forces that occur during an earthquake. This includes ensuring that the formwork is adequately braced and anchored to prevent collapse or movement. Additionally, the connections between the different formwork elements should be strong and flexible enough to accommodate the seismic movements without compromising the overall stability of the structure. Furthermore, the selection of materials for the steel formwork should be appropriate for the seismic conditions, considering factors like strength, ductility, and corrosion resistance. Overall, proper design, construction, and material selection are crucial when using steel formwork in areas with high seismic activity to ensure the safety and integrity of the structure.

- Steel formwork is a versatile and durable option for handling different concrete early age strength development. Due to its strength and rigidity, steel formwork provides excellent support during the initial stages of concrete curing. It can withstand the high pressures exerted by fresh concrete, ensuring that the formwork remains intact and stable during the early age strength development. Additionally, steel formwork allows for efficient and precise placement of concrete, enabling proper consolidation and uniform curing. Overall, steel formwork is a reliable choice that can effectively handle the varying early age strength development of concrete.

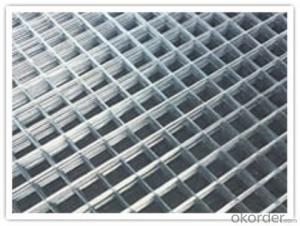

- In construction projects, various tie systems are commonly employed in steel formwork to ensure stability and support during the concrete pouring process. The primary types of tie systems utilized in steel formwork are as follows: 1. Tie rods and wing nuts: This tie system is extensively used in steel formwork. It involves the insertion of steel rods through the formwork panels, which are then secured using wing nuts. This system allows for convenient and effortless assembly and disassembly of the formwork. 2. Shear connectors: In situations where there is a requirement to transfer shear forces between the formwork and the concrete, shear connectors are employed. These connectors usually consist of steel bars embedded in the concrete and connected to the formwork. 3. Steel form ties: Steel form ties are used to hold the formwork panels together, maintaining the desired shape and alignment during concrete pouring. These ties are typically constructed from steel and are available in various lengths and sizes to cater to diverse formwork requirements. 4. Adjustable formwork systems: Designed to offer flexibility in adjusting the formwork to different shapes and sizes, these systems often incorporate adjustable brackets and clamps. They allow for effortless and precise alignment of the formwork panels. 5. Stay-in-place formwork systems: Stay-in-place formwork systems are specifically designed to remain in place even after the concrete has cured, eliminating the need for formwork removal. These systems find application in scenarios where the formwork is intended to become a permanent part of the structure, such as in bridges or tunnels. Overall, the selection of a tie system in steel formwork depends on factors such as project requirements, structural design, and specific construction site conditions. It is crucial to choose a tie system that can provide the required stability and support for the formwork, while also considering factors such as ease of installation, reusability, and cost-effectiveness.

- Yes, there are specific design considerations for steel formwork. These include factors such as the strength and stability of the steel structure, the weight-bearing capacity of the formwork, ease of assembly and disassembly, compatibility with different concrete mixtures, and the ability to withstand various site conditions such as weather and construction loads. Additionally, the design should also consider the reusability and durability of the steel formwork system to ensure cost-effectiveness and sustainability in construction projects.

- Steel formwork contributes to the overall sustainability of the construction industry in several ways. Firstly, steel formwork is highly durable and can be reused multiple times, reducing the need for new materials and minimizing waste. This not only reduces the environmental impact of construction but also lowers costs for builders. Additionally, steel formwork allows for precise and efficient construction, resulting in less material wastage and overall resource savings. Lastly, the strength and versatility of steel formwork enable the construction of more durable and long-lasting structures, reducing the need for frequent repairs or replacements, which further contributes to the sustainability of the construction industry.

- Steel formwork contributes to the overall moisture resistance of a structure in several ways. Firstly, steel formwork is designed to be highly durable and resistant to corrosion. This means that it can withstand exposure to moisture without deteriorating or losing its structural integrity. Additionally, steel formwork is constructed with tight joints and connections, minimizing the potential for water infiltration. Unlike traditional timber formwork, steel formwork does not shrink or warp when exposed to moisture, ensuring that there are no gaps or openings that would allow water to seep into the structure. Furthermore, steel formwork is often coated with protective finishes, such as epoxy or galvanized coatings, which provide an extra layer of moisture resistance. These coatings act as a barrier, preventing water from penetrating the steel and reaching the concrete structure. By providing a strong, watertight enclosure during the construction process, steel formwork helps to prevent moisture from entering the structure. This is particularly important for structures that will be exposed to external elements, such as bridges or buildings located in humid or rainy climates. Overall, steel formwork's durability, tight joints, and protective coatings contribute to the overall moisture resistance of a structure, ensuring that it remains structurally sound and free from water damage.