CNBM Steel Formwork with Q345 Material for Civil Engineeing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

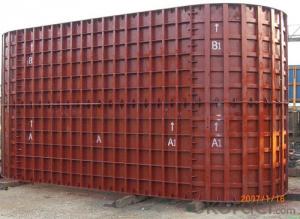

Introduction for Steel Formwork :

Steel Formwork:used in highway,railway,bridge,tunnel and shearing wall,etc.Our company CNBM which is one of the largest State-Owned Enterprises in China which established in 1984 , has gained the confirmation from the specialist of China Architecture Scence Institute, and has been used by many building operation units and has been highly praised.In 2014, the total turnover volume of CNBM exceeds US$410 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises !

Characteristic for Wholly Steel Formwork :

1. High Smooth Surface

2. Convex ling for Edge Rib

3. Specialized Connection Pin for Edge Rib Connection

4. High Stiffness for Steel Surface

5. Light Weight for saving producing cost

6. Fast Separate and Easy transport

7. Recycling using

8. Scientific and Reasonable design to meet different working condition

Parameter and Specification :

Code | Size (mm) | Weight (KG) | Code | Size (mm) | Weight (KG) |

P12021 | 1200*2100*55 | 102.96 | P4018 | 400*1800*55 | 28.3 |

P12018 | 1200*1800*55 | 88.4 | P4015 | 400*1500*55 | 23.8 |

P12015 | 1200*1500*55 | 74.15 | P4012 | 400*1200*55 | 19.1 |

P12012 | 1200*1200*55 | 60.11 | P4009 | 400*900*55 | 14.6 |

P10018 | 1000*1800*55 | 76.01 | P4007 | 400*750*55 | 12.3 |

P10015 | 1000*1500*55 | 63.96 | P4006 | 400*600*55 | 9.95 |

P10012 | 1000*1200*55 | 60.11 | P3018 | 300*1800*55 | 20.7 |

P10009 | 1000*900*55 | 39.32 | P3015 | 300*1500*55 | 17.4 |

P9018 | 900*1800*55 | 70.89 | P3012 | 300*1200*55 | 14 |

P9015 | 900*1500*55 | 59.47 | P3009 | 300*900*55 | 10.7 |

P9012 | 900*1200*55 | 48.03 | P3007 | 300*750*55 | 8.8 |

P7518 | 750*1800*55 | 57.8 | P3006 | 300*600*55 | 7.3 |

P7515 | 750*1500*55 | 48.47 | P3004 | 300*400*55 | 5.46 |

P7512 | 750*1200*55 | 39.16 | P2515 | 250*1500*55 | 15.17 |

P7509 | 750*900*55 | 29.85 | P2512 | 250*1200*55 | 12.24 |

P7507 | 750*750*55 | 24.81 | P2509 | 250*900*55 | 9.32 |

P6018 | 600*1800*55 | 43.1 | P2507 | 250*750*55 | 7.71 |

P6015 | 600*1500*55 | 36.3 | P2506 | 250*600*55 | 6.39 |

P6012 | 600*1200*55 | 31.7 | P2015 | 200*1500*55 | 11.6 |

P6009 | 600*900*55 | 23.9 | P2012 | 200*1200*55 | 9.4 |

P6007 | 600*750*55 | 18.55 | P2009 | 200*900*55 | 7.1 |

P6006 | 600*600*55 | 16.25 | P2007 | 200*750*55 | 5.9 |

P5018 | 500*1800*55 | 36.27 | P2006 | 200*600*55 | 6.39 |

P5015 | 500*1500*55 | 30.15 | P2004 | 200*450*55 | 3.64 |

P5012 | 500*1200*55 | 25.55 | P1515 | 150*1500*55 | 9.5 |

P5009 | 500*900*55 | 20.38 | P1506 | 150*600*55 | 4 |

P5007 | 500*750*55 | 15.48 | P1504 | 150*450*55 | 2.98 |

P5006 | 500*600*55 | 13.58 | P1015 | 100*1500*55 | 7.5 |

Code | Size (mm) | Weight (KG) |

P1012 | 100*1200*55 | 6.9 |

P1009 | 100*900*55 | 4.6 |

P1007 | 100*750*55 | 3.8 |

P1006 | 100*600*55 | 3.1 |

P1004 | 100*450*55 | 2.33 |

E1515 | 150*150*1500 | 15.2 |

E1512 | 150*150*1200 | 12.26 |

E1509 | 150*150*900 | 9.34 |

E1507 | 150*150*750 | 7.77 |

E1506 | 150*150*600 | 6.46 |

E1504 | 150*150*450 | 4.87 |

E1015 | 100*150*1500 | 13.13 |

E1012 | 100*150*1200 | 10.61 |

E1009 | 100*150*900 | 8.07 |

E1006 | 100*150*600 | 5.44 |

Y1018 | 100*150*1800 | 14.56 |

Y1015 | 100*150*1500 | 12.29 |

Y1012 | 100*150*1200 | 9.72 |

Y1009 | 100*150*900 | 7.46 |

Y1007 | 100*150*700 | 6.19 |

Y1006 | 100*150*600 | 5.19 |

Y1004 | 100*150*450 | 3.92 |

J0018 | 50*50*1800 | 4.34 |

J0015 | 50*50*1500 | 3.7 |

J0012 | 50*50*1200 | 2.94 |

J0009 | 50*50*900 | 2.3 |

J0007 | 50*50*750 | 1.9 |

J0006 | 50*50*600 | 1.5 |

J0004 | 50*50*450 | 1.13 |

FAQ :

1. Who are we ?

We , CNBM , are a State-Owned Enterprise which established in 1984 , have 32 years experience ,enjoy high reputation .

2. Our Advantage :

Customized products , we have our own R&D department , we can design the drawing and suggest the suitable solution for your project .

3. Our after-Sales Service :

The international Sales Manager and Engineer can go to your job site for work direction and help you deal with your project .

Factory Photos :

- Q:Can steel formwork be used for both small and large concrete pours?

- Yes, steel formwork can be used for both small and large concrete pours. Steel formwork provides durability, strength, and stability, making it suitable for various sizes of concrete pours. Its versatility allows for easy customization and adjustment to accommodate different project requirements.

- Q:How does steel formwork affect construction speed and efficiency?

- Steel formwork can significantly enhance construction speed and efficiency in several ways. Firstly, steel formwork is highly durable and can withstand multiple uses, resulting in reduced time and cost associated with replacing or repairing formwork materials. This allows construction projects to progress smoothly without delays caused by formwork damage or deterioration. Moreover, steel formwork provides a high level of accuracy and precision during the construction process. Its rigid structure ensures consistent dimensions and alignment, resulting in uniformity in concrete placement and reducing the need for adjustments or corrections. This precision saves time and effort, enabling construction teams to work more efficiently and complete projects in a timely manner. Additionally, steel formwork is known for its versatility and adaptability. It can be easily customized to fit various shapes and sizes, allowing for the construction of complex structures with ease. This flexibility eliminates the need for extensive manual cutting or modification of formwork materials, saving time and labor. Furthermore, steel formwork offers a quick assembly and dismantling process. Its modular design allows for easy installation and removal, reducing the time required for formwork preparation and cleanup. This efficiency not only accelerates construction progress but also minimizes downtime between different stages of the project. Lastly, steel formwork is known for its excellent load-bearing capacity. Its sturdy construction can support heavy concrete loads, enabling faster construction cycles by allowing for larger pours and reducing the number of pour breaks. This increases the productivity of the construction team, as they can complete larger sections of the structure in a shorter period. In conclusion, steel formwork positively impacts construction speed and efficiency by providing durability, accuracy, versatility, quick assembly, and load-bearing capabilities. Its contribution to reducing construction time, minimizing errors, and optimizing resource utilization makes it a preferred choice for many construction projects.

- Q:How does steel formwork affect the overall construction site safety?

- Steel formwork can significantly enhance overall construction site safety. Its strength and durability ensure stability and structural integrity during concrete pouring and curing processes. The use of steel formwork reduces the risk of formwork collapse or failure, which can cause serious accidents and injuries. Additionally, steel formwork's fire-resistant properties provide an added layer of safety, minimizing the potential for fire-related incidents. Overall, steel formwork promotes a safer construction site by reducing potential hazards and enhancing the structural stability of the project.

- Q:How is steel formwork disassembled?

- Steel formwork is typically disassembled using a systematic approach to ensure safe and efficient removal. The process involves several steps: 1. Inspection: Before disassembling the steel formwork, it is crucial to inspect the structure for any signs of damage or wear. This helps identify any potential hazards and allows for necessary repairs or replacements before starting the disassembly process. 2. Removal of accessories: Start by removing any accessories attached to the steel formwork, such as scaffolding, support beams, or tie rods. These accessories are often essential for the stability of the formwork system, so their removal should be done carefully and in a controlled manner. 3. Removing concrete debris: Next, remove any concrete debris or remnants that may have adhered to the steel formwork. This can be done using tools like hammers, chisels, or wire brushes. Proper cleaning of the formwork ensures smooth disassembly and prevents any future complications. 4. Dismantling panels: Begin dismantling the steel formwork panels one by one. This is typically done by removing the connecting pins, bolts, or screws that hold the panels together. The order of disassembly should follow the reverse order of the assembly process, starting from the top and working downwards. 5. Handling and storage: As each panel is disassembled, it should be carefully handled to prevent any damage or injury. Once disassembled, the panels should be properly labeled and stored in a designated area to ensure easy retrieval for future use or transportation. 6. Post-disassembly inspection: After the steel formwork has been completely disassembled, it is important to conduct a final inspection. This allows for the identification of any damaged or worn-out components that may require repairs or replacement before the next use. Overall, the disassembly process of steel formwork requires careful planning, attention to detail, and adherence to safety guidelines. Following these steps ensures the proper removal of the formwork while maintaining the integrity of the structure and ensuring the safety of workers involved.

- Q:What are the common safety guidelines when working with steel formwork in confined spaces?

- When working with steel formwork in confined spaces, some common safety guidelines include ensuring proper ventilation to prevent the buildup of hazardous gases, regularly monitoring the atmosphere for toxic substances, providing adequate lighting and emergency exit routes, wearing appropriate personal protective equipment such as gloves, safety glasses, and respiratory protection, training workers on the potential hazards and safe work practices, and having a standby person outside the confined space to monitor and assist if needed.

- Q:Can steel formwork be used for architectural concrete slabs with embedded elements?

- Yes, steel formwork can be used for architectural concrete slabs with embedded elements. Steel formwork provides a strong and durable framework for pouring and shaping concrete. It allows for precise and accurate placement of embedded elements such as pipes, electrical conduits, and reinforcement bars. Steel formwork also offers the advantage of reusability, making it a cost-effective choice for construction projects. Moreover, the smooth surface of steel formwork can result in a high-quality finish for architectural concrete slabs.

- Q:How does steel formwork contribute to the overall structural stability of the building?

- Steel formwork contributes to the overall structural stability of a building in several ways. Firstly, it provides a strong and rigid framework that supports the weight of concrete during the pouring and curing process. This ensures that the concrete is evenly distributed and prevents any sagging or deformation. Secondly, steel formwork helps in maintaining the desired shape and dimensions of the concrete elements, such as columns, beams, and walls, which are crucial for the overall stability of the structure. Additionally, steel formwork offers high tensile strength and durability, allowing it to withstand the forces imposed by the concrete and any external loads, thus enhancing the structural integrity of the building.

- Q:How does steel formwork contribute to the overall moisture resistance of the structure?

- Steel formwork contributes to the overall moisture resistance of a structure by providing a strong and durable barrier against water penetration. Unlike traditional wooden formwork, steel formwork does not absorb or retain moisture, reducing the risk of water damage and mold growth. The tight joints and smooth surface of steel formwork also prevent water from seeping into the structure, ensuring its long-term integrity and reducing maintenance costs.

- Q:Can steel formwork be used for curved or irregular structures?

- Indeed, curved or irregular structures can be constructed using steel formwork. The utilization of steel formwork provides design flexibility and enables the easy shaping or fabrication of intricate geometries. Its strength and durability allow it to endure the immense pressure exerted during the pouring of concrete. With the ability to effortlessly adjust and adapt, steel formwork is well-suited for constructing structures with distinctive architectural designs or intricate layouts that incorporate curves, bends, or irregular shapes. Furthermore, the implementation of steel formwork guarantees a sleek finish to the concrete surface, resulting in structures of exceptional quality and aesthetic appeal.

- Q:What are the common design considerations for steel formwork in bridge construction?

- Some common design considerations for steel formwork in bridge construction include the structural integrity and stability of the formwork system, the ability to withstand the weight and pressure of the concrete during pouring and curing, the ease of assembly and disassembly, the ability to accommodate variations in bridge geometry and dimensions, and the durability of the formwork system to withstand harsh environmental conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM Steel Formwork with Q345 Material for Civil Engineeing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches