Engineered Wood Planks

Engineered Wood Planks Related Searches

Wd 40 For Stainless Steel Drill Bits For Stainless Steel Best Solar Inverter For Rv Led Headlight Kits For Trucks Led For Cannabis Growing Hs Code For Solar Inverter Solar Shades For Windows Ready Made Bars For Home Stock Symbol For Alcoa Aluminum Msds Sheet For MagnesiumHot Searches

Hdf Board For Sale sintra board for sale Gypsum Board Price Per Sheet In India High Density Mdf Board Suppliers 5 8 Type X Gypsum Board Price Lasani Wood Sheet Price Polyurethane Insulation Board Price White Melamine Board Price Black Melamine Board Price Mdf Price Per Sheet Pre Laminated Board Price List 4Mm Mdf Sheet 1220X2440Mm Price 6Mm Mdf Board Price 18Mm Ply Board Price Ply Board Price List Partex Board Price List Hdf Board Price India 19Mm Ply Board Price Hpl Board Price Magnum Board PriceEngineered Wood Planks Supplier & Manufacturer from China

Okorder.com is a professional Engineered Wood Planks supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Engineered Wood Planks firm in China.Hot Products

FAQ

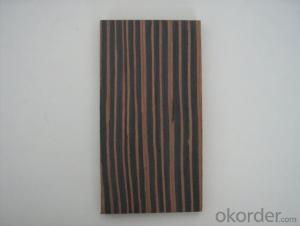

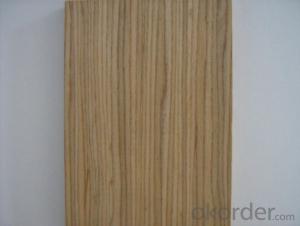

- Cut Slicing - The cut is a round of vertical cut logs, producing a veneer with a ruled ridge.

- Rift-Cut (Rift-Cut) - cut the cut veneer used in a variety of oak manufacturing. The xylem of oak is stretched from the center of the logs, like the curved spokes of the wheels.

- What are the specifications for veneer?

- The price from a more than one square to several hundred and one square have, the general import of expensive than domestic

- Often, the processing of natural vines is done by slicing the method. The process flow is as follows

- The use of these saws to produce veneer, the board rate is high, the quality of thin wood is better, chopper machine is more efficient.

- How to seize the key to solve the problem of slow development of paste veneer process?

- According to professional survey found that upgrading the veneer process not only to ensure the quality of veneer and production level, but also need a suitable veneer glue

- What are the quality items of veneer piles?

- by the bark part is later growth, material color deep, Dense, hard material, said latewood (autumn wood, summer material)

- Different veneer has different production processes

- . Of course, there are some furniture enterprises to understand the technology more comprehensive

- The Veneer dyeing quality requirements

- Quality requirements: the color is not bleaching, the whole batch of goods not more than three kinds of color, flat, humidity does not exceed 10%, no residue of chemicals, no smell.

- Slicing of thin slices of wood

- after cooking treatment; the cooking process should be reduced to more than 40 ℃, it should slow down the heating rate