Contech Geogrid

Contech Geogrid Related Searches

Fridge With Freezer On Bottom Driveway Pillars With Lights Blu Ray Player With Recorder Blu Ray Player With Internet Geogrid In Retaining Walls 1708 Biaxial Fiberglass Tape Pullout Resistance Of Geogrid Geogrid Warp Knitting Machine Srw 3 Series Geogrid Biaxial Plastic GeogridHot Searches

Fiberglass Scaffolding For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale Geogrid Fabric For Sale Gas Powered Core Aerator For Sale Revolution 4 Propeller For Sale Alabaster Carving Stone For Sale Geogrid For Sale Near Me Tensar Geogrid For Sale Geogrid For Sale Ex Display Log Cabins For Sale Photoelectric Cells For Sale Athletic Lockers For Sale Cubicle Partitions For Sale Stearman Propeller For Sale Palram Greenhouses For Sale Gumbo Bowls For Sale Suzuki Propellers For Sale Freight Crates For Sale Outhouse Sheds For SaleContech Geogrid Supplier & Manufacturer from China

Okorder.com is a professional Contech Geogrid supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Contech Geogrid firm in China.Hot Products

FAQ

- What is geogrid, what is the role?

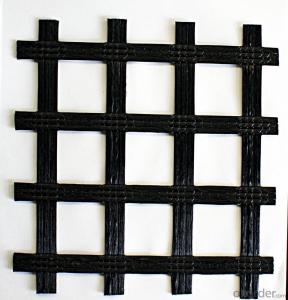

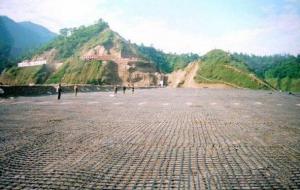

- To enhance the problemGlass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce reflection crack.

- The typical lifespan of geogrids can vary depending on factors such as the quality of the materials used, the specific application, and the environmental conditions. However, geogrids are designed to have a long service life and can often last for several decades under normal conditions.

- Geogrids help in reducing construction equipment requirements by providing reinforcement and stability to the soil. This means that less heavy machinery is needed to compact and stabilize the ground, resulting in cost savings and more efficient construction processes. Geogrids distribute the load evenly, prevent soil erosion, and improve soil bearing capacity, reducing the need for extensive excavation and grading work.

- Yes, geogrids are suitable for reinforcing bridge abutment backfills. Geogrids are commonly used in civil engineering projects to enhance soil stability and provide reinforcement. They can effectively distribute the load and prevent soil movement, thereby improving the overall strength and performance of bridge abutment backfills.

- Yes, geogrids are effective in preventing soil creep. Geogrids provide additional reinforcement to the soil, increasing its stability and resistance to movement. They help distribute the forces acting on the soil, reducing the potential for creep and maintaining slope integrity.

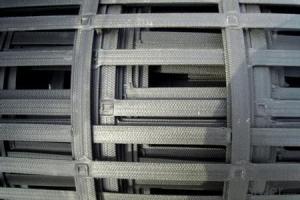

- There are several installation methods for geogrids, including direct placement, trenching, and anchoring. Direct placement involves laying the geogrid directly on the soil or subgrade surface. Trenching involves excavating a trench and placing the geogrid in the trench, then backfilling it with soil. Anchoring involves securing the geogrid to the ground using stakes, pins, or other mechanical devices. The specific installation method chosen depends on the project requirements and the specific application of the geogrid.

- Some factors that can affect the performance of geogrids under cyclic loading include the type and quality of the geogrid material, the installation method, the magnitude and frequency of the cyclic loading, the soil conditions, and the presence of any additional reinforcement or confinement.

- Geogrids help reduce maintenance costs by improving the stability and longevity of soil and pavement structures. They provide reinforcement and prevent soil erosion, minimizing the need for frequent repairs or replacements. Additionally, geogrids distribute loads more evenly, reducing stress on the infrastructure and preventing cracking or settlement issues that would require costly maintenance.