Concrete Formwork System

Concrete Formwork System Related Searches

Primer For Galvanized Steel H S Code For Stainless Steel Wd 40 For Stainless Steel Spray Paint For Stainless Steel Glue For Stainless Steel Step Bit For Stainless Steel Magnets For Stainless Steel Caulking For Stainless Steel Steel Vessels For Kitchen Best Solar Inverter For HomeHot Searches

Steel Mesh Panels For Sale Cheap High Tea Sets For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Used Solar Inverter For Sale Portable Led Signs For Sale Stone Hot Water Bottles For Sale Large Led Screens For Sale 1/4 Aluminum Plate For Sale H4 Led Headlight Bulbs For Sale Flexible Solar Cells For Sale Air Pump For Aquarium Price Inverter Size For Solar System Solar Edge Inverter For Sale Aluminum Bar Stock For SaleConcrete Formwork System Supplier & Manufacturer from China

Okorder.com is a professional Concrete Formwork System supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Concrete Formwork System firm in China.Hot Products

FAQ

- The load capacities of steel formwork systems can differ based on their specific type and design. Steel formwork systems are generally recognized for their ability to bear heavy loads. In the case of horizontal formwork systems, like slab formwork, the load capacities can range from 60 to 100 kN/m2 or even higher, depending on factors such as slab thickness and support spacing. This allows for the effective construction of reinforced concrete slabs and beams that can withstand substantial loads. Vertical formwork systems, such as wall formwork and column formwork, are constructed to withstand the weight of fresh concrete and the lateral pressure exerted during pouring. The load capacities of these systems can vary based on the height and width of the structure being formed. Usually, wall formwork systems can support loads ranging from 50 to 80 kN/m2, while column formwork systems can handle loads ranging from 60 to 100 kN/m2. It is important to note that these load capacities serve as general guidelines and may differ based on the design and manufacturer of the steel formwork system. It is always recommended to refer to the manufacturer's specifications and guidelines to ensure that the formwork system is used within its designated load capacities for safe and efficient construction.

- There are several types of steel used in formwork construction, each with their own specific characteristics and applications. 1. Mild Steel: This is the most commonly used type of steel in formwork construction. It is affordable, readily available, and easy to work with. Mild steel is suitable for most formwork applications and offers good strength and durability. 2. High Tensile Steel: This type of steel is stronger than mild steel and has a higher tensile strength, making it ideal for heavy-duty formwork structures. High tensile steel provides enhanced resistance to bending and deformation under heavy loads, making it suitable for large-scale construction projects. 3. Reinforcing Steel: Reinforcing steel, also known as rebar, is used in formwork construction to reinforce concrete structures. It is typically made of carbon steel and is available in various grades and sizes. Reinforcing steel is used to increase the tensile strength of concrete and improve its resistance to cracking and structural failure. 4. Stainless Steel: Stainless steel is used in formwork construction when corrosion resistance is a primary concern. It is particularly suitable for formwork exposed to harsh environmental conditions or in contact with corrosive materials. Stainless steel offers excellent resistance to corrosion, making it a durable and long-lasting option for formwork construction. 5. Alloy Steel: Alloy steel is a type of steel that is mixed with other elements to enhance its properties. It is commonly used in formwork construction for its high strength, toughness, and resistance to wear and tear. Alloy steel can withstand heavy loads and is often used in formwork systems that require superior performance and durability. Overall, the choice of steel used in formwork construction depends on the specific requirements of the project, including load-bearing capacity, durability, and resistance to corrosion. It is important to select the appropriate type of steel to ensure the safety and longevity of the formwork structure.

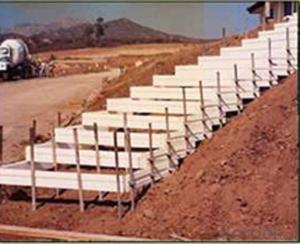

- Yes, steel formwork generally requires special expertise or training for installation. The process involves understanding the structural requirements, proper handling and assembling of steel components, as well as ensuring the formwork's stability and safety. Expertise in steel construction and knowledge of formwork systems are usually necessary for a successful installation.

- Steel formwork is a versatile option that can be used for both simple and complex architectural designs. It can be shaped and customized to different sizes and shapes, making it suitable for a variety of projects. Its flexibility allows for the creation of intricate and unique forms. In addition, steel formwork offers excellent strength and stability, enabling it to withstand the pressures and forces exerted during the concrete pouring process. This makes it an ideal choice for constructing structures with complex shapes and designs. Moreover, steel formwork is durable and can be reused, making it a cost-effective solution for projects involving both simple and complex architectural designs. Overall, steel formwork is a reliable and efficient option that can be used in a wide range of architectural designs, regardless of their complexity.

- Some common challenges faced during steel formwork reassembly include aligning and securing the individual components properly, ensuring the formwork is structurally sound and stable, dealing with any damage or corrosion on the steel components, coordinating with other construction activities to avoid delays, and ensuring proper safety measures are in place for workers involved in the reassembly process.

- Steel formwork construction has specific quality control measures in place to guarantee compliance with standards and specifications, as well as to ensure its safety and reliability in construction projects. An important quality control measure involves inspecting the steel formwork materials prior to their use. This includes checking for defects, such as cracks, rust, or other damage, that may compromise the formwork's integrity and strength. Additionally, the materials must be checked for correct dimensions and smoothness to ensure proper fit and a smooth surface finish. Another measure involves inspecting the steel formwork during and after the construction process. This entails verifying that the formwork is properly assembled and secured, with all connections and joints aligned and tightened correctly. Furthermore, the formwork must be checked for signs of deformation, like bending or twisting, which could compromise its structural integrity. Apart from inspections, quality control measures also include testing the steel formwork to assess its strength and durability. This may involve conducting load tests to determine its maximum load capacity and evaluating its resistance to environmental factors such as corrosion, fire, and moisture. Documentation and record-keeping are also crucial quality control measures for steel formwork construction. This involves maintaining detailed records of inspections, tests, and any repairs or modifications made to the formwork. Such documentation ensures traceability of the construction process and allows for auditing if necessary. In conclusion, these quality control measures are vital to ensure that steel formwork construction is of high quality, meets the required standards, and provides a safe and reliable support system for concrete during construction.

- Steel formwork is constructed by following a systematic process that involves several steps. The first step is to determine the dimensions and requirements of the concrete structure that needs to be formed. This includes taking into account the shape, size, and design of the structure. Once the dimensions are finalized, steel sheets are cut according to the required sizes and shapes. These sheets are then assembled and connected using different methods such as welding or bolting, depending on the design and strength requirements. The connections between the steel sheets are essential to ensure stability and rigidity of the formwork. After the assembly of the steel sheets, additional components such as stiffeners, braces, and beams are added to provide structural support and reinforcement to the formwork. These components help to distribute the load evenly and prevent any deformation during the pouring and curing of the concrete. Once the formwork structure is fully assembled and reinforced, it is placed in position and secured to the ground or existing structures using anchors or supports. This ensures that the formwork remains stable and in place during the concrete pouring process. The final step involves waterproofing the steel formwork to prevent any leakage or seepage of water from the concrete. This is typically done by applying a waterproofing membrane or coating to the inner surface of the formwork. Overall, the construction of steel formwork requires careful planning, precise cutting, accurate assembly, and proper reinforcement. It is crucial to follow industry standards and guidelines to ensure the structural integrity and safety of the formwork system.

- Steel formwork is a viable option for hotel or hospitality construction projects. It offers numerous advantages compared to other formwork types like wood or concrete. Primarily, steel formwork boasts exceptional durability, allowing it to withstand the heavy loads and pressures associated with construction endeavors. This makes it suitable for constructing hotels with large and intricate structures. Secondly, steel formwork is reusable, resulting in cost savings and reduced construction time. This proves particularly advantageous in hotel or hospitality projects where efficiency and promptness are crucial. Moreover, steel formwork ensures a smooth and high-quality finish on concrete surfaces. This is especially vital in the hotel and hospitality industry, where aesthetics play a significant role. The sleek finish provided by steel formwork enhances the overall appearance of hotels, creating a visually appealing and luxurious environment for guests. Additionally, steel formwork allows for greater design flexibility as it can be easily shaped and adjusted to meet specific project requirements. This is a valuable asset in hotel or hospitality construction projects, where unique and personalized designs are often desired to create a distinct and memorable guest experience. In conclusion, steel formwork is a suitable choice for hotel or hospitality construction projects due to its durability, reusability, ability to provide a smooth finish, and flexibility in design.