3 Inch Rigid Foam Insulation

3 Inch Rigid Foam Insulation Related Searches

Steel Frames For Furniture Wd 40 For Stainless Steel Spray Paint For Stainless Steel Drill Bits For Stainless Steel Best Inverter For Solar System Led Table Lamps For Home Best Solar Inverter For Rv Stainless Steel Box With Lid Stainless Steel Bucket With Lid Inverter For 5kw Solar SystemHot Searches

Used Foam Board Insulation For Sale Roxul Insulation For Sale Fiber Sheet Price In India Fiber Roofing Sheets Price In Pakistan Plastic Fiber Sheet Price Extruded Polystyrene Insulation Board Price Polyurethane Insulation Board Price Polyisocyanurate Rigid Foam Insulation Price Mineral Wool Insulation Price List Styrofoam Insulation Sheets Price Roof Insulation Price Multi Layer Insulation Price Polystyrene Insulation Price Ceiling Fan Lowest Price Rocksol Insulation Cost Used Foam Board Insulation For Sale Fiberglass Scaffolding For Sale Plastic Roof Tiles For Sale Fiberglass Panels For Sale Fiberglass Greenhouses For Sale3 Inch Rigid Foam Insulation Supplier & Manufacturer from China

Okorder.com is a professional 3 Inch Rigid Foam Insulation supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 3 Inch Rigid Foam Insulation firm in China.Hot Products

FAQ

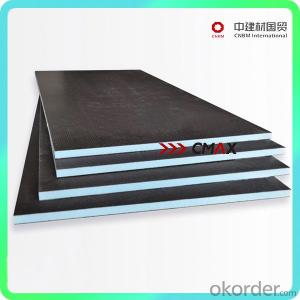

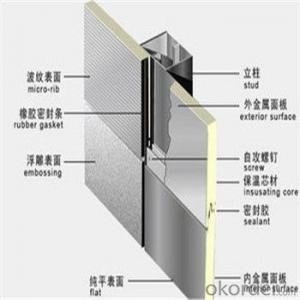

- Yes, sandwich panels can be used for noise barriers. Sandwich panels are typically made of two outer layers of rigid materials, such as metal or wood, with a layer of insulating material in between. This insulating layer helps to absorb and dampen sound waves, making sandwich panels an effective choice for noise barriers. The insulating material in sandwich panels can be made of various materials, such as mineral wool or polyurethane foam, which have excellent sound absorption properties. These materials are designed to trap and dissipate sound energy, preventing it from passing through the barrier and reducing the noise levels on the other side. Sandwich panels for noise barriers can be customized to meet specific noise reduction requirements. Different thicknesses and densities of the insulating layer can be used to achieve the desired level of sound insulation. Additionally, the outer layers can be designed to be reflective or absorptive, depending on the desired acoustic performance and aesthetic preferences. Sandwich panels offer several advantages for noise barrier applications. They are lightweight, making them easy to install and transport. They also have a high strength-to-weight ratio, providing structural integrity to withstand environmental factors such as wind and vibrations. Furthermore, sandwich panels can be designed to be durable and resistant to corrosion, ensuring long-lasting performance in outdoor environments. In conclusion, sandwich panels are a suitable choice for noise barriers due to their sound absorption properties, customization options, and durability. They can effectively reduce noise levels and provide a quieter environment for various applications, such as highways, factories, residential areas, and commercial buildings.

- Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

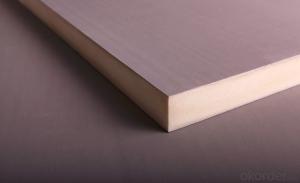

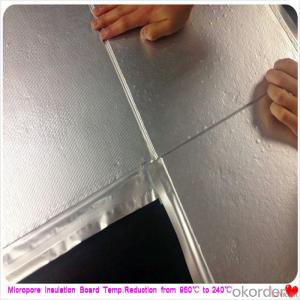

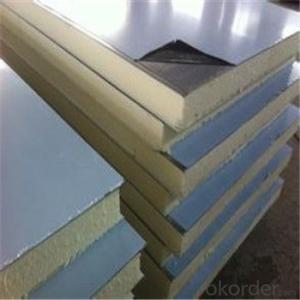

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- That depends on the savvy! Way more than difficult!

- Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Color steel room life in general how many years

- Polystyrene board is too fragile with the general use of extruded plate ah to protect the membrane waterproof layer

- Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Sun room roof was originally glass, so hot, want to add a layer of foam in the above sandwich panels, what sticky more solid anti-aging!

- scaffolding must be set vertical and horizontal sweep longitudinal rod should be used at right angle fastener fixed at the bottom of the pipe at 200mm at the vertical pole should be fixed with fast nuts By the vertical pole pole