wall Angle / Metal Stud and Track In

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Drywall system is a light weight non-load wall consisting of steel framing profile, to be cladded with gypsum board or other types of cladding sheets.

The profile especially designed for internal partitions in aspect of residential and commercial constructions.

Product Applications:

Product used for internal constructions gypsum drywall partition such as hotels, terminal building, bus station, theatres, shopping malls, factories, office buildings, and etc.

Product Advantages:

1.Light,good strength,cauterization resistance and water resistance

2.Matching magnesium fire-proof board,gypsum board and many other wall and ceiling board

3.Moisure-proof ,shock-resistant,high-effcient and environmentally-friendly

4.Easy and fast for installation,time-saving

5. Prompt delivery, high quality ,competitive price and complete sets of styles

6.We can supply you the products based on your specific requirements

Main Product Features:

(1) Lightweight and high strength: 3-4 kg/m2 (1/10 of half brick wall), with yield strength 400mpa.

(2) Environment-friendly : galvanized steel-no radiation, have no harm to our health and not pollute the environment.

(3) Products with fillisters : Setting some fillisters in both sides of the keels in a selective way, in order to strength the keels' vertical points and intensity.

(4) The metal stud with hole : one of our product is the special hole on C-stud every 600mm, which is easy for workers to install the electric lines and water tubes.

(5) Various sizes of metal track and metal stud : we are able to manufacture German, Japan and Aus-American types etc..We can meet your customized demands.

(6) Factory direct sale price : We have our own factory to produce raw materials----galvanized(zinc coated) steel, as well as the product line, so we can provide you a lowest price.

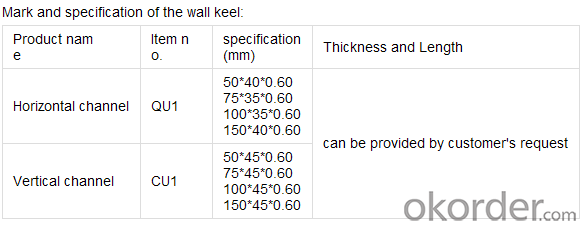

Product Specifications:

Images:

- Q:Light steel keel wall to withstand the number of wind load

- According to the thickness of the keel, the height of the partition, supporting the keel, supporting the card is complete, the wall is also about 200 ~ 600Pa wind pressure is not obvious deformation.

- Q:How to construct double - sided double gypsum board partition wall

- Installation of vertical keel, light steel vertical keel. Keel must be vertical, vertical keel inserted at both ends along the top keel and along the keel, adjust the vertical and positioning accuracy, with a core pulling rivets fixed.

- Q:Shanghai Light Steel keel ceiling Shanghai plant decoration office building decoration light steel keel ceiling wall

- Effective space division The internal space of the plant is mainly divided by the operator according to their actual use requirements to make reasonable use of space, if the plant has a large number of equipment, it is not appropriate to set too much partition and partition, as far as possible to the ground color or with some Color identification to the division of the region, with the identification of the area to avoid too much color, so not only the regional division is not obvious also feel dizzy, and some plants can be clearly divided into the equipment area and office area, such a plan It is now more common because it is easy to manage. Then in the design of such a plant must master the data and the close combination of space, but also take into account the equipment area and the working area of the work area is smooth and dust, noise interference.

- Q:Light steel keel wall to remove the price

- General demolition is to ask the workers, the price of workers depends on the local price, should be the price of each place are different, hope to have a role in you.

- Q:Light steel keel wall waterproof

- 1. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) Used for bonding with the substrate, to achieve 100% continuous sticky. 2. Use 1032 to enhance the polyester cloth Used to enhance the coating of tensile, tear resistance and fatigue resistance. 3. The use of steel coated excellent 1011 metal roof for high-elastic waterproof coating (grass-roots) By enhancing the gap of the mesh structure of the polyester cloth, the intermediate layer and the base coating are fully infiltrated and integrated to effectively enhance the sealing performance of the coating. 4. Use steel coated excellent 1021 metal roof dedicated high-elastic waterproof coating (surface)

- Q:The designer said the solid wood flooring keel hit the prefabricated board after the lack of effort in the future may not be strong?

- 1: you have the conditions or bricklayers, practice: build the wall of the place, you can add a reverse beam (plus a beam on the floor) and then wall, reinforced concrete beam; another direct to do the word steel or channel to do Beam, pay attention to the two heads to be on the point of support. Build the wall again. ? 2: do light steel keel gypsum board wall accidentally wear a hole. Is a short time to be. Not moisture, is easy. 3: the floor can be made of wood, the material with a little bigger. Encrypt a little bit. The problem is not big, other solid floor to do on the ground fixed point has changed the day.

- Q:How to install damping sound insulation felt

- Keel on the installation of poly-mao acoustic insulation board (two-layer board folder sound insulation felt, sheet and sound insulation stitching treatment), noise board between the seams and sound insulation board and roof, floor joints for construction sealant seal.

- Q:Light steel keel with what screws fixed gypsum board

- 2.5cm self-tapping screw! Do not matter where you can use nails. In foreign countries, taking into account the factors of the earthquake, heaven and earth keel and vertical keel can not be nailed.

- Q:Curved gypsum board wall technology.

- If the curvature is not large, then the gypsum board can be bent directly over, the deformation of the gypsum board itself is enough, if the curvature is too large, then only cut the stitching, and then patch repair, no matter what method, Do not use anything evenly spray water and then bend into the arc, gypsum board wet water, the intensity is very low, although dry, the strength and good board is not very different, but there may be deformation of the plate

- Q:Gypsum board partition wall how to sound insulation

- Close the gypsum board to install the keel, filled with rock wool in the keel, and then use the gypsum board with a screw on the keel, you can achieve adequate sound insulation. If you want a better sound insulation, you can use thicker gypsum board.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

wall Angle / Metal Stud and Track In

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords