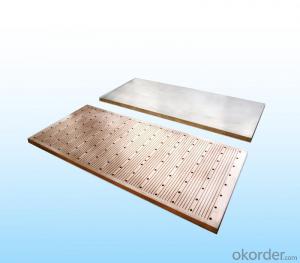

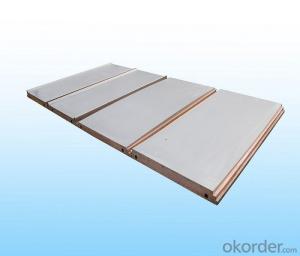

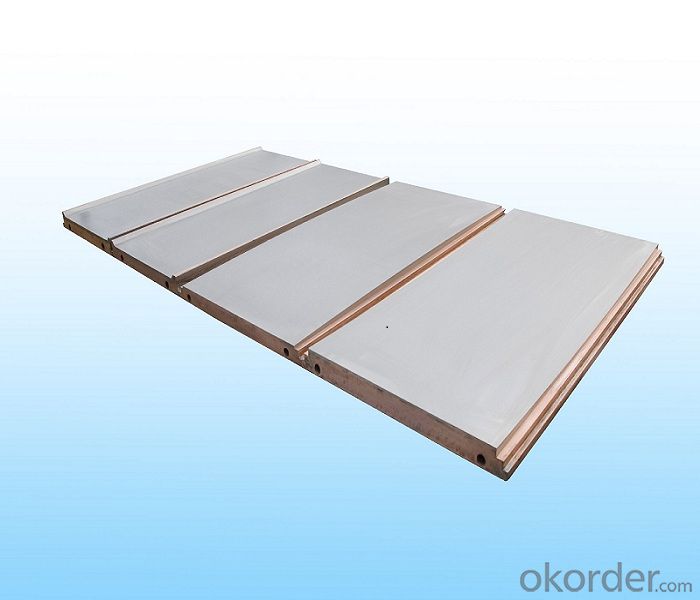

Ultra-thin slab copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 200 pc/month

- Option:

- 1530

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Description

We can design and manufacture Ultra-thin slab copper mould plate used on continuous casting machine.

Size Length1530mm Width 1100mm , Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We are the leading professional designer and manufacturer for copper mould plates & tube.

The copper moulds supplied by CNBM adopt advanced European technology. Nowadays, CNBM is one of the largest copper moulds supplier and exporter with more than 30% market share in domestic market and 5% in the world market.

2.Main Features

Steady and high quality,

Packing : Strong, export worthy wooden cases. High quality products and excellent service.

Fast shipment; 30-40days for production;

Our products with world-class quality, competitive price, flexible payment terms, speedy delivery and excellent service.

We are supplying Size Length1530mm Width 1100mm , Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

3. Images

4.Specification

Thin slab

We can design as per the customer’s specific requirements.

Length 1200-2000mm

Width 1100-1200 mm

Material Cr-Zr-Cu, Cu Ag. Coating Ni-Co、Cr、Ni-Fe.

We can design as per the customer’s specific requirements.

- Q:I‘m trying to join different sheet metals together (thick sheet) and I‘m looking for a way to join/stick metals like copper, aluminum and Iron together without bolting or welding. Someone mentioned some Cyanoacetate glues can apparently join metal together but I don‘t know will it work?

- Cyanoacrylates usually require that parts fit tightly with only small gaps. Otherwise it's doesn't cure well. Strength is best in very thin layers. The strength of the joint will depend on how close you can get the sheets to fit, and also the net amount of contact area. You need to keep in mind that at best the strength of the glue is maybe 1/8 that of the metal.

- Q:I have an old sculpture made of sheet copper. It has some areas where the patina is missing.

- Heat the copper sheet until it does black (with copper oxide) and then carefully add ethanoic acid. You will have made verdigris.

- Q:A copper sheet with length 1.0 m, width 0.50 m, and thickness 1.0 mm is oriented so that its largest surface area is perpendicular to a magnetic field of strength 6.4 T. The sheet carries a current of 3.5 A across its length. What is the magnitude of the force on this sheet?what is the formula that involves Area when finding the Fb??can someone tell me?

- Imagine the sheet made up of N thin strips of copper running lengthwise across the sheet, length L 1m, with infinitely thin insulation strips between each copper strip. The current thru each strip is 3.5A/N. The force on each strip due to the B field is F (i/N)LB pushing the strip sideways. So the total force on the sheet is N*(i/N)LB iLB, just as though the sheet were a single wire. Magnitude iLB 3.5A*1m*6.4T 22.4 N answer

- Q:im doing my chemistry h/w and this question came up and i have looked in my book and on the sheet but there is no answer it would be very helpful if u could help me on this question thank you

- firstly because it's soluble, so it would just wash out, secondly because it doesn't dye things propaerly, third because it goes white when it dries out too fast. Oh and it's irritant.

- Q:When were mirrors invented and by who?

- I would guess the problem is the air flow meter.

- Q:When doing copper reliefs, there is a step of using sodium sulfide to scrub the surface of copper plate. The copper plate will turn black. Is the black substance copper sulfide?

- Because the solubility product of CuS is very small, the reaction shifts to the rightH+ in H2S can also oxidize Ag, no wonder

- Q:How much copper temperature?

- High temperature copper, copper plate is generally recommended Jiashan Rongchang sliding bearing is less than 300 degrees, Rongchang copper is self lubrication with a copper alloy (CuZn24Al6) self-lubricating plate, combined with the self lubrication performance and wear resistance of copper alloy solid lubricant, which used in the process without refueling and maintenance.

- Q:plz help like any ways ThanX

- Try Sluggo from Spray-N-Grow. It's a biodegradable slug control that is safe and organic but still effective. The active ingredient in it is a mineral found naturally in soil so when the stuff breaks down it actually enriches your garden. Very easy to apply too.

- Q:Some things your average person doesn‘t know how to do, but won‘t take more than a few weeks to learn(less than that is preferable) I‘ve learned some coin tricks and morse code and plan on learning to juggle. Just some neat little things to occupy me. Any and all answers appreciated! Thanks! (:

- Juggling different sized objects (golf ball soft ball stick or knife) Whittling - carving animals or fish from wood with just a knife Soldering copper - get a small torch and proper solder and copper fittings and solder into figurines robots, small metal shears and copper sheet to add features.

- Q:WHy does copper need to be heated before you can make it into something!?

- Copper is a metal. Most metals have a very high melting point and are solids at room temperature. Copper is highly malleable and ductile (that means it can be bent and made into thin wires and sheets). To make it into something, you have to have to melt it because as a solid it is rigid and can't be poured into a mould or bent highly, etc. When you melt it, the copper atoms move farther apart since they gain kinetic energy and become a fluid. After they become a fluid, they are able to flow and can be made into stuff easily. In a layman's view, copper (or any metal for that matter of fact) has to be melted before it can be made into stuff because it can flow around. You can melt it, put it into a mould and then it takes the shape of the mould when it solidifies. For Example, you take candle wax. It melts off the candle and falls on the candle holder. It then cools down and solidifies, taking the shape of a droplet when it fell down. The candle wax became a perfect droplet shaped thing, but was originally a part of a cylindrical candle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ultra-thin slab copper mould plate used on continuous casting machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 pc

- Supply Capability:

- 200 pc/month

- Option:

- 1530

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords