Tinplate For Aerosol Can-CHBA

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

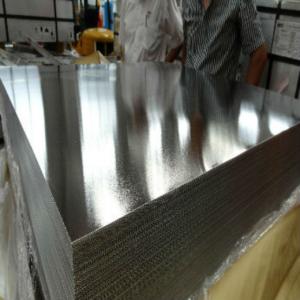

General information of Tinplate for Aerosol Can

|

Steel Type |

SPCC |

|

Temper (BA&CA) |

T1~T5, DR8 |

|

Coating |

2.8~8.4g/m2 |

|

Thickness & Tolerance |

0.15~0.5mm (Tolerance:±0.01mm) |

|

Width & Tolerance |

600~1000 mm(Tolerance: +2/-0mm) |

|

I.D |

508 MM |

|

Coil Weight |

3~10 MT |

|

Passivation |

311 |

|

Oiling |

DOS |

|

Surface Finish |

Bright ,Stone ,Silver ,Matte |

|

Min Order |

25 Tons for 1 20 feet FCL |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Standard Available |

GB/T2520-2000, JIS G3303, ASTM A623, BS EN10202 |

|

Lead Time |

35 days after receiving buyer's original L/C or Prepayment |

|

Special specifications are available on customers' requirements. | |

Technical data of Tinplate for Aerosol Can

|

Chemical Composition(%) |

Mechanical Property |

|

C:0.04~0.06 |

Yield Strength: (Mpa):280~320 |

|

Si:0.01~0.03 |

TensileStrength: (Mpa):340~390 |

|

Mn:0.18~0.22 |

Elongation:20%~30% |

|

P:0.014~0.016 |

------------- |

|

S:0.006~0.009 |

Application of Tinplate for Aerosol Can

Tinplate is widely used for making all types of containers such as artistic cans, tea cans, painting cans,

chemical package cans and metal printing etc. Its applications are not limited to containers; recently,

tinplate has also been used for making electrical machinery parts and many other products.

Equipment and Facility of Tinplate Steel

Tin Coating Line of Tinplate Steel

Cold Rolling Mill Batch Annealing Furnaces

Cutting Line Stock Area

Quantity Control System of Tinplate Steel

- Q:How does tinplate compare to plastic packaging in terms of sustainability?

- Tinplate packaging generally has a better environmental sustainability profile compared to plastic packaging. Tinplate is highly recyclable and often contains a significant percentage of recycled content. It has a longer lifespan and can be reused multiple times before recycling. On the other hand, plastic packaging is often made from fossil fuels, non-biodegradable, and has a limited recycling rate. Additionally, plastic waste can persist in the environment for hundreds of years, contributing to pollution and harm to wildlife. Therefore, tinplate packaging is considered a more sustainable option in terms of reducing waste and minimizing environmental impact.

- Q:What are the different methods of reusing tinplate packaging?

- There are several methods of reusing tinplate packaging, including repurposing it for storage or organization, using it as a decorative item or plant pot, transforming it into a DIY craft project, or donating it to organizations that can find alternative uses for it. Another option is to recycle tinplate packaging to be used in the production of new materials.

- Q:What are the different ways tinplate packaging can be decorated?

- There are several different ways tinplate packaging can be decorated, including lithography, embossing, printing, and labeling. Lithography involves applying a design or image onto the tinplate using a printing process. Embossing creates raised or recessed designs on the surface of the tinplate, adding texture and dimension. Printing can be done using various techniques such as screen printing, flexography, or digital printing to apply graphics, logos, or text onto the tinplate. Lastly, labeling involves attaching pre-printed labels onto the tinplate packaging, allowing for custom branding or labeling options.

- Q:Can tinplate be used as a water tower? Is hot water durable?

- But because tinplate is very thin iron sheet, forming force is poorer, cannot make water tower. However, the tinplate has the characteristics of corrosion resistance and non toxicity. It can be used as the inner container of the water tower. It is sanitary and durable. However, when cleaning, must not scratch the surface of the tin layer, otherwise it is easy to rust.

- Q:Can tinplate be used for pet food packaging?

- Yes, tinplate can be used for pet food packaging. Tinplate is a common material used in food packaging due to its durability, corrosion resistance, and ability to maintain product freshness. It is also widely recyclable, making it an environmentally friendly choice. Therefore, tinplate is a suitable option for packaging pet food as it provides a reliable and safe container for storing and preserving pet food products.

- Q:What are the different ways to open tinplate containers?

- There are several different ways to open tinplate containers, depending on their design and intended purpose. Common methods include using a can opener, pulling a tab or ring pull, twisting off a lid, or using a tool like a pry bar or knife to pry the lid off.

- Q:What are the main challenges in tinplate inventory management?

- One of the main challenges in tinplate inventory management is the fluctuating demand for tinplate products, which requires accurate forecasting and planning to avoid overstocking or stockouts. Additionally, tinplate is prone to rusting, so proper storage and handling techniques are crucial to maintain product quality. Lastly, managing multiple tinplate sizes and specifications can be complex, requiring efficient tracking and organization systems to ensure the right products are available when needed.

- Q:Can tinplate be used for petrochemical packaging?

- Yes, tinplate can be used for petrochemical packaging. Tinplate is a type of steel coated with a layer of tin, which provides excellent corrosion resistance and protection against chemical reactions. This makes it suitable for storing and transporting petrochemical products safely.

- Q:What is the purpose of tin coating on tinplate?

- The purpose of tin coating on tinplate is to provide a protective layer that prevents the iron from rusting and extends the shelf life of the product. Additionally, the tin coating enhances the appearance of the tinplate, making it more visually appealing to consumers.

- Q:How does tinplate affect the overall cost of packaging production?

- Tinplate can significantly impact the overall cost of packaging production due to its higher price compared to other materials such as aluminum or plastic. Its production, coating, and transportation costs can add up, making it more expensive for manufacturers. However, tinplate offers excellent durability, protection, and aesthetic appeal, which can enhance the value and marketability of the packaged product. Ultimately, the cost-effectiveness of tinplate packaging depends on factors like the specific product, target market, branding strategy, and overall budget.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei,China |

| Year Established | 2009 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America;South America; Eastern Europe Southeast Asia; Africa; Mid East Eastern Asia; Western Europe; Central America Northern Europe; Southern Europe; Domestic Market |

| Company Certifications | HACCP;ISO 9001:2008;ISO 14001:2004 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 270,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High;Average |

Send your message to us

Tinplate For Aerosol Can-CHBA

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords