Stainless Steel Coil Cold Rolled 304 With Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil Cold Rolled 304 With Good Quality

Cold Rolled stainless steel Coil with good quality is one of the raw material of the cold

rolled stainless steel Coil, which can be used directly in many places. Stainless Steel

(Stainless Steel) is short for acid-proof Stainless Steel, resistant to weak corrosive

medium such as air, steam, water, or with a Stainless Steel grade.

2.Main Features of Prefabricated Steel Structure High Building Project

Weld-ability: The purpose of the different requirement for welding performance are

different.1 Kind of tableware generally do not require the performance of welding, even

including some pot class enterprise. But the vast majority of products all need raw

materials welding performance is good, like the 2 kinds of tableware, thermos flask, steel

pipes, water heaters, water dispensers, etc.

Heat resistant performance Heat resistant performance refers to the high temperature

stainless steel can still maintain its excellent physical and mechanical properties. Carbon:

the influence of carbon in austenitic stainless steel is formed strong and steady. Set the

austenitic austenitic area and expand elements. Carbon formation of austenite is about 30

times that of the nickel, the ability of carbon is a kind of gap elements, through the solid

solution strengthening can significantly increase the strength of the austenitic stainless

steel. Carbon austenitic stainless steel can be improved in high concentration chloride

(e.g., 42% MgCl2 boiling solution) in the performance of the resistance to stress corrosion.

But, in the austenitic stainless steel, carbon is often seen as the harmful elements, this is

mainly due to the corrosion of stainless steel used in some conditions, such as welding or

heating by 450 ~ 850 ℃), carbon steel with chromium in forming high chromium Cr23C6

type carbon compounds which can lead to local chromium depletion, make steel corrosion

resistance especially resistant to intergranular corrosion performance degradation. So.

Since the 60 s of the development of new Cr-Ni austenitic stainless steel is mostly carbon

content less than 0.03% or 0.02% of the ultra-low carbon type.

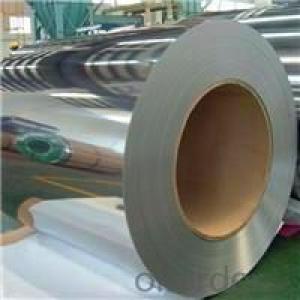

3. Stainless Steel Coil Cold Rolled 304 With Good Quality Images

4. Stainless Steel Coil Cold Rolled 304 With Good Quality Specification

Ferritic stainless steel Chromium containing 15% ~ 30%. Its corrosion resistance,

toughness and weldability with chromium content increases with the increase of chloride

stress corrosion resistance is superior to other types of stainless steel, fall into this

category of Crl7, Cr17Mo2Ti, Cr25, Cr25Mo3Ti, Cr28, etc. Ferritic stainless steel because

of the high chromium content, corrosion resistance and oxidation resistance are relatively

good, but the mechanical properties and process performance is poorer, more used to

stress less acid structure and steel used as antioxidant. This kind of steel to withstand

atmosphere, nitric acid and corrosion of the brine solution, and has good high temperature

oxidation resistance, low thermal expansion coefficient, etc, used in nitric acid and food

factory equipment, also can make work under high temperature parts, such as gas turbine

parts, etc.

Austenitic, ferritic duplex stainless steel The advantages of both austenitic and ferritic

stainless steel, and has the superplasticity. Austenite and ferrite The title Each accounts

for about half of the stainless steel. In the case of contain low C, Cr content was 18% ~

18%, Ni content at 3% ~ 3%. Some steel containing Mo, Cu, Si, Nb, Ti, N and other

alloying elements. This kind of steel both austenite and ferrite stainless steel, the

characteristics of compared with ferrite, plasticity and toughness is higher, no room

temperature brittleness, intergranular corrosion resistance and welding performance were

significantly increased, while maintaining a ferritic stainless steel of 475 ℃ brittleness and

high thermal conductivity, has the characteristics of superplasticity. Compared with

austenitic stainless steel, high strength and resistance to intergranular corrosion and

resistance to chloride stress corrosion is improved obviously. Duplex stainless steel has

excellent resistance to pitting corrosion performance, is also a kind of nickel and stainless

steel.

5. Applications of Stainless Steel Coil 304 With Good Quality

1. Kitchenware: tableware, cookware, Stoves…

2. Food packing: storage cans, food containers…

3. Construction: bridge, roofing, wall, decoration, bathroom accessories…

4. Precision instruments: electrical products, aerospace…

5. Others: automotive parts, machine building, chemical processing, farming…

6.FAQ of Stainless Steel Coil 304 With Good Quality

We have organized several common questions for our clients,may help you sincerely:

How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we willprovide necessary

follow-up service assurance.

How is the packaging and delivery?

Standard export packing (Coil: waterproof paper + protective steel ring; Circle: wooden

box), or as your requirement and the delivery term is based on the project.

- Q:Are 111 stainless steel strips suitable for wastewater treatment pipelines?

- Depending on the specific requirements and conditions of the pipeline, wastewater treatment pipelines can potentially use stainless steel strips like 111 stainless steel. Stainless steel is well-known for its resistance to corrosion, making it an ideal choice for applications that involve exposure to water and wastewater. However, the appropriateness of using 111 stainless steel strips for wastewater treatment pipelines is contingent upon various factors. These factors include the presence and concentration of chemicals in the wastewater, the temperature and pressure conditions, and the overall design and construction of the pipeline system. It is crucial to take these factors into account and seek guidance from experts or engineers who specialize in wastewater treatment pipelines to ensure the selection of the appropriate material. In certain situations, specific grades of stainless steel like 304 or 316 may be more commonly utilized for wastewater treatment pipelines due to their superior resistance to corrosion. These grades exhibit exceptional resistance to a wide range of corrosive chemicals typically encountered in wastewater treatment processes. Ultimately, determining the suitability of 111 stainless steel strips for wastewater treatment pipelines requires a comprehensive analysis of the project's specific requirements and the compatibility of the material with the operational conditions of the pipeline.

- Q:Can stainless steel strips be formed into different shapes?

- Yes, stainless steel strips can be formed into different shapes through various metalworking processes such as bending, rolling, and stamping.

- Q:Can stainless steel strips be used in chemical processing plants?

- Chemical processing plants can utilize stainless steel strips. Stainless steel possesses exceptional resistance to corrosion, rendering it extremely appropriate for use in chemical-rich settings. These strips withstand both organic and inorganic chemicals, encompassing acids, alkalis, and salts. Moreover, stainless steel is easily cleaned and maintained, thus being a favored option in hygienic-minded chemical processing plant applications. These strips are also capable of enduring high temperatures, qualifying them for employment in numerous processes like distillation, evaporation, and filtration. In sum, stainless steel strips prove themselves as reliable and long-lasting selections for chemical processing plants due to their corrosion resistance, low maintenance requirements, and capacity to endure harsh surroundings.

- Q:Are stainless steel strips suitable for laser cutting?

- Stainless steel strips are indeed appropriate for laser cutting. When it comes to cutting various materials, including stainless steel, laser cutting proves to be a highly precise and efficient method. The laser beam's high energy density allows for a clean and accurate cut, without any distortion or harm to the metal. Stainless steel, renowned for its corrosion resistance and durability, is a popular material choice in industries like automotive, aerospace, and construction. Laser cutting offers numerous advantages for stainless steel strips, such as reducing material waste, maintaining tight tolerances, and enabling intricate designs. Moreover, laser cutting provides a flawlessly smooth and burr-free edge finish, enhancing the aesthetic appeal of the stainless steel strips.

- Q:What are the common uses of stainless steel strips in the semiconductor industry?

- Stainless steel strips have a variety of common uses in the semiconductor industry due to their unique characteristics and properties. Some of the major applications include: 1. Etching Process: Stainless steel strips are often utilized as etching masks during the semiconductor fabrication process. The strips are resistant to various chemical etchants and offer excellent corrosion resistance, making them ideal for protecting specific areas of the semiconductor surface during the etching process. 2. Wafer Handling: Stainless steel strips are used for handling delicate silicon wafers throughout the manufacturing process. The strips provide a clean and contamination-free surface, preventing any damage or contamination that could affect the quality of the wafers. 3. Cleanroom Construction: Stainless steel strips are commonly used in the construction of cleanrooms within the semiconductor industry. These strips are preferred due to their high resistance to corrosion, durability, and ability to withstand harsh cleaning chemicals used in cleanroom maintenance. 4. ESD Protection: Electrostatic discharge (ESD) can cause significant damage to sensitive semiconductor components. Stainless steel strips are used as grounding strips or ESD protection strips to dissipate any static charges and prevent damage to the semiconductor devices during the assembly and testing processes. 5. Heat Exchangers: Stainless steel strips are employed in the construction of heat exchangers used to regulate temperature during various semiconductor manufacturing processes. The strips' excellent thermal conductivity and corrosion resistance make them suitable for transferring heat efficiently while maintaining a clean and sterile environment. 6. Surface Mount Technology (SMT): Stainless steel strips are also used in the SMT process, where electronic components are directly mounted onto the surface of a printed circuit board. The strips serve as solder stencils, facilitating the precise application of solder paste onto the board, ensuring accurate placement of components during the assembly process. Overall, stainless steel strips are valued in the semiconductor industry for their corrosion resistance, cleanliness, durability, and ability to withstand extreme conditions, making them indispensable in various stages of semiconductor manufacturing.

- Q:What are the different grades of stainless steel used for strips?

- The different grades of stainless steel used for strips can vary depending on the specific application and requirements. Some commonly used grades include 304, 316, 430, and 201. Each grade has its own unique properties and characteristics, such as corrosion resistance, strength, and heat resistance. The selection of the grade depends on factors like the environment, load-bearing capacity, aesthetic appeal, and cost considerations.

- Q:Are 111 stainless steel strips suitable for cryogenic storage tanks?

- Yes, 111 stainless steel strips are suitable for cryogenic storage tanks. 111 stainless steel is a type of austenitic stainless steel that offers excellent corrosion resistance, high strength, and good toughness, making it an ideal choice for cryogenic applications. It can withstand extremely low temperatures without becoming brittle or losing its mechanical properties. Additionally, 111 stainless steel has good weldability and formability, making it easier to fabricate into the required shape for cryogenic storage tanks. Overall, 111 stainless steel strips are a reliable and durable material for cryogenic storage tanks, ensuring the safe and efficient storage of cryogenic liquids or gases.

- Q:Are stainless steel strips suitable for automotive body panels?

- Yes, stainless steel strips are suitable for automotive body panels. Stainless steel has excellent corrosion resistance, durability, and aesthetic appeal, making it a popular choice for various automotive applications. It provides strength and can withstand harsh environmental conditions, ensuring the longevity and appearance of the vehicle's body panels.

- Q:Are 111 stainless steel strips resistant to scaling at elevated temperatures?

- Yes, 111 stainless steel strips are resistant to scaling at elevated temperatures. The composition and properties of 111 stainless steel make it highly resistant to oxidation and scaling when exposed to high temperatures. This type of stainless steel contains a higher percentage of chromium, which forms a protective oxide layer on the surface of the strips. This oxide layer acts as a barrier, preventing the steel from reacting with oxygen and other elements in the atmosphere. As a result, the 111 stainless steel strips maintain their integrity and resist scaling even when subjected to elevated temperatures.

- Q:What is the typical price range for 111 stainless steel strips?

- The typical price range for 111 stainless steel strips can vary depending on factors such as the quantity, quality, and supplier. However, a rough estimate for the price range could be anywhere from $1 to $5 per strip.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Coil Cold Rolled 304 With Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords