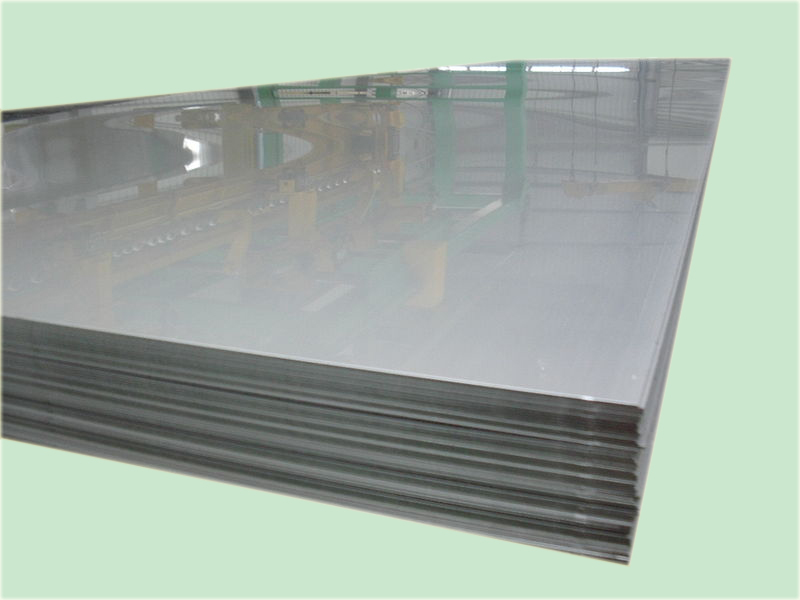

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

304L stainless Steel Sheet

1. Chemical composition

|

C |

Si |

Mn |

P |

S |

Ni |

Cr |

|

Max0.03 |

Max1.00 |

Max2.00 |

Max0.045 |

Max0.03 |

9.0-13.0 |

18.0-20.0 |

2. Mechanical properties

|

Yield Strength |

Tensile |

Elongation |

Hardness (HV) |

Hardness (HRB) |

|

≥175 |

≥480 |

≥40 |

≤200 |

≤90 |

3. Standard: AISI, ASTM, GB, EN, DIN, JIS

4. Surface: 2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size: Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms: T/T or L/C

8. Packing: Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time: Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q:What are the different types of surface patterns for stainless steel strips?

- Stainless steel strips can be adorned with various surface patterns, catering to specific aesthetic and functional preferences. Among the commonly used patterns are: 1. Brushed Finish: This particular pattern involves brushing the steel surface with a fine abrasive material, resulting in a consistent linear pattern. It offers a sleek and sophisticated appearance while reducing the visibility of scratches and fingerprints. 2. Mirror Finish: As the name implies, mirror finish creates a highly reflective and lustrous surface on stainless steel strips. Through meticulous polishing, the steel attains a mirror-like appearance. This pattern is often employed in applications where visual appeal is paramount, such as architectural and decorative elements. 3. Embossed Pattern: Embossed patterns are achieved by pressing or rolling stainless steel strips through a textured roller. This process creates raised designs or textures, enhancing visual appeal and adding a unique touch. Embossed patterns can range from simple geometric shapes to intricate designs. 4. Perforated Pattern: Perforated stainless steel strips feature evenly distributed small holes or perforations on the surface. This pattern not only adds visual interest but also offers functional benefits such as improved ventilation, light diffusion, and acoustic properties. It finds common usage in architectural and industrial applications. 5. Diamond Pattern: Resembling a series of small diamonds, this raised pattern is achieved by embossing the stainless steel strips with a diamond-shaped design. It provides excellent slip resistance, making it suitable for surfaces requiring traction, like walkways, stairs, and industrial flooring. 6. Linen Pattern: Linen pattern imparts a textured surface to stainless steel strips, akin to the appearance and tactile sensation of linen fabric. Achieved by rolling the strips through a patterned roller, it introduces a subtle linear texture. Linen pattern adds visual interest and can help conceal minor surface imperfections. These examples represent only a fraction of the diverse surface patterns that can be applied to stainless steel strips. Each pattern possesses unique characteristics and advantages, enabling a plethora of applications across various industries and settings.

- Q:What are the different types of surface treatments for stainless steel strips?

- Stainless steel strips can be treated in various ways to achieve different results and benefits. Let's explore the different options available: 1. Pickling: By immersing stainless steel strips in an acid solution like nitric or hydrochloric acid, pickling eliminates impurities and contaminants, leaving behind a clean and smooth surface finish. 2. Passivation: This method involves creating a protective oxide layer on the surface of stainless steel strips, enhancing their resistance against corrosion. This can be done by immersing the strips in a nitric acid solution or applying a citric acid paste. 3. Electropolishing: Through an electrochemical process, electropolishing removes a thin layer of material from stainless steel strips, resulting in a shiny and smooth surface finish. Not only does it enhance the appearance, but it also improves corrosion resistance and cleanability. 4. Brushing: Abrasive materials like wire brushes or abrasive pads are used in brushing to create a brushed or satin finish on stainless steel strips. This treatment helps conceal surface imperfections and provides a uniform and decorative appearance. 5. Grinding: Mechanical grinding involves using abrasive wheels or belts to remove material from the surface of stainless steel strips. This treatment can achieve a specific surface roughness or eliminate any defects or blemishes. 6. Coating: Adding a protective material, such as paint or powder coating, to the surface of stainless steel strips enhances corrosion resistance and improves the aesthetic appearance. Coatings are available in a wide range of colors and finishes. 7. Polishing: By using abrasive materials like polishing compounds or buffing wheels, polishing creates a mirror-like finish on stainless steel strips. This treatment enhances appearance and can also improve corrosion resistance. Each of these surface treatments offers unique advantages depending on the desired outcome and application requirements. It is crucial to consider factors such as corrosion resistance, aesthetics, and functionality when selecting the appropriate treatment for stainless steel strips.

- Q:Can stainless steel strips be used in jewelry making?

- Yes, stainless steel strips can be used in jewelry making. Stainless steel is a durable and corrosion-resistant material, making it an excellent choice for creating long-lasting and high-quality jewelry pieces. Stainless steel strips can be easily shaped, cut, and polished to create various jewelry components such as earrings, bracelets, necklaces, and rings. Additionally, stainless steel is hypoallergenic, making it suitable for individuals with sensitive skin or metal allergies. It also offers a sleek and modern look, making it a popular choice for contemporary jewelry designs.

- Q:What are the different types of surface finishes for stainless steel strips?

- Stainless steel strips usually undergo different types of surface finishes to improve their appearance, enhance their durability, and increase their resistance to corrosion. Below are some common finishes: 1. Mill Finish: The stainless steel strip is left in its original state after production, resulting in a non-reflective and dull appearance. It may have visible imperfections or marks from manufacturing. 2. No. 1 Finish: Also called HRAP (hot-rolled annealed and pickled), this finish involves annealing the stainless steel strip and pickling it in acid. It creates a smooth, reflective surface with a slightly matte look. No. 1 finish is frequently used in industrial applications where appearance is not a primary concern. 3. No. 2B Finish: Achieved by cold-rolling the stainless steel strip and subsequent annealing and pickling, this finish offers a bright, semi-reflective surface. It strikes a balance between appearance and corrosion resistance, making it suitable for kitchen appliances and architectural elements. 4. No. 4 Finish: Also known as brushed or satin finish, this finish is obtained by mechanically polishing the stainless steel strip with abrasive materials. It results in a smooth, matte appearance with fine parallel lines, giving it a brushed texture. No. 4 finish is commonly used for decorative purposes like furniture, elevator panels, and trims. 5. No. 8 Finish: Referred to as mirror finish, this finish is achieved by polishing the stainless steel strip to create a highly reflective surface. It has a mirror-like appearance with excellent reflectivity. No. 8 finish is often employed in architectural and decorative applications that require a polished, high-end look, such as signage, jewelry, and automotive trims. Apart from these primary surface finishes, there are also specialized finishes available for specific applications, such as embossed, patterned, and colored finishes. These finishes further enhance the aesthetic appeal and functionality of stainless steel strips in various industries.

- Q:Are stainless steel strips suitable for pressure piping?

- Yes, stainless steel strips are suitable for pressure piping. They have high strength, excellent corrosion resistance, and can withstand high pressure environments, making them a reliable choice for various applications in pressure piping systems.

- Q:What are the common applications of stainless steel strips?

- Stainless steel strips have a wide range of applications due to their various beneficial properties. Here are some common applications of stainless steel strips: 1. Construction: Stainless steel strips are commonly used in the construction industry for various purposes. They are extensively used in structural components, roofing, cladding, and architectural features due to their corrosion resistance, durability, and aesthetic appeal. 2. Automotive industry: Stainless steel strips find applications in the automotive industry for manufacturing components like exhaust systems, trim, grills, and fuel tanks. They are preferred for their resistance to heat, corrosion, and impact, ensuring longevity and safety in vehicles. 3. Kitchen appliances: Stainless steel strips are widely used in the production of kitchen appliances such as countertops, sinks, cookware, and utensils. Their corrosion resistance, easy cleaning, and hygienic properties make them a popular choice for the food industry. 4. Medical equipment: Stainless steel strips are extensively used in the manufacturing of medical instruments and equipment. They are preferred for their biocompatibility, non-reactive nature, and resistance to sterilization methods, making them suitable for surgical tools, implants, and medical devices. 5. Electronics: Stainless steel strips are used in the electronics industry for various applications such as connectors, terminals, springs, and shielding. Their electrical conductivity, durability, and resistance to corrosion make them ideal for these applications. 6. Oil and gas industry: Stainless steel strips are commonly used in the oil and gas industry for manufacturing pipes, tanks, valves, and other equipment. Their resistance to corrosion and high temperatures make them suitable for harsh environments and ensure the integrity of equipment. 7. Aerospace industry: Stainless steel strips find applications in the aerospace industry for manufacturing aircraft components, including structural parts, fasteners, and fittings. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance contribute to the safety and performance of aircraft. 8. Decorative and architectural purposes: Stainless steel strips are used for decorative purposes in architecture and interior design. They can be shaped, polished, and finished to create attractive and durable features like handrails, elevator panels, signage, and sculptures. These are just a few examples of the common applications of stainless steel strips. With their versatile properties, they are utilized in various industries where strength, corrosion resistance, hygiene, and aesthetics are essential.

- Q:How do stainless steel strips compare to stainless steel sheets?

- Stainless steel strips are narrower and thinner than stainless steel sheets. They are commonly used for applications that require a more compact and flexible material, such as in construction or automotive industries. On the other hand, stainless steel sheets are larger and thicker, offering more strength and stability. They are often utilized for structural purposes or when a larger surface area is needed, like in kitchen appliances or architectural cladding. Ultimately, the choice between strips and sheets depends on the specific requirements of the project at hand.

- Q:Are 111 stainless steel strips resistant to scaling at elevated temperatures?

- Yes, 111 stainless steel strips are resistant to scaling at elevated temperatures.

- Q:What industries commonly use stainless steel strips?

- Stainless steel strips are widely used in various industries due to their exceptional properties and versatility. One industry that commonly utilizes stainless steel strips is the automotive industry. These strips are used for manufacturing various automotive components such as exhaust systems, trim, and decorative elements due to their corrosion resistance, strength, and aesthetic appeal. Another industry that extensively uses stainless steel strips is the construction industry. These strips are employed in the construction of infrastructure, such as bridges, tunnels, and buildings, as they offer excellent structural integrity, durability, and resistance to environmental factors. Stainless steel strips are also utilized for roofing, siding, and cladding applications. The food processing and packaging industry also rely heavily on stainless steel strips. These strips are preferred for their hygienic properties, as they are easy to clean, resistant to bacterial growth, and non-reactive to food products. Stainless steel strips are used in the production of equipment like conveyors, mixers, and food storage containers. Furthermore, the medical and pharmaceutical industries heavily rely on stainless steel strips for their equipment and instruments. Stainless steel's biocompatibility, corrosion resistance, and ease of sterilization make it ideal for surgical tools, dental instruments, medical implants, and pharmaceutical manufacturing equipment. Other industries that commonly use stainless steel strips include the aerospace industry, where they are used for aircraft components, and the energy industry, where they are utilized in power plants, oil and gas processing, and renewable energy systems. Overall, the diverse range of properties offered by stainless steel strips makes them a popular choice across various industries, providing durability, corrosion resistance, hygiene, and strength, among other benefits.

- Q:Are 111 stainless steel strips suitable for chemical reactors?

- Yes, 111 stainless steel strips are suitable for chemical reactors. They possess excellent corrosion resistance, high temperature resistance, and good mechanical properties, making them suitable for handling various chemicals and operating conditions within a reactor.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | 2005 |

| Annual Output Value | Above US$5.3 Million |

| Main Markets | Europe, China |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tian Jin |

| Export Percentage | 30% |

| No.of Employees in Trade Department | 40 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | Above 50,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

SUS304L stainless Steel Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords