SS 201 Stainless Steel Pipe Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

ss 201 stainless steel pipes price per kg

Material | 304:0cr18ni9, 0cr17ni8 201:1cr17mn6ni5n,1cr13mn9ni1n 316:0cr17ni12 or as customer’s request |

Size(round pipe) | 9.5, 12.7, 15.9, 17, 18, 19.1, 20, 21, 22.2, 23, 25.4, 28, 318, 35, 60, 63.5, 73, 76.2, 88.9, 101.6, 114.3, 127, 133, 59, 168, 219 mm or customized |

Size (square pipe) | 10×10,12×12,18×18,23×23,38×38,50×50,70×70,100×100,20×10,23×10,24×12,25×13,36×23, 40×20,50×20,60×15,75×45,80×60,95×45,100×60,150×100 mm or customized |

Size (oval pipe) | 30×15,80×40 mm os customized |

Thickness | 0.24-3 mm |

Length | 6m or according to customer’s request |

Outer diameter | 6.35-219mm |

Tolerance | Outer diameter :±0.2mm |

Thickness :±0.02mm | |

Length :±0.5mm | |

Process method | Code drawn, annealed with nitrogen protection, ultrasonic,automatic shape, polished |

Finishing | A: sanded B: 400#-600# mirror C: hairline brushed D: TIN titanlum E : HL brushed & mirror (two kinds of finishing for one pipe) |

Chemical Composition | |||||||

Material | C | Si | Mn | P | S | Cr | Ni |

201 | ≤0.12 | ≤0.75 | 9.5-12.5 | ≤0.045 | ≤0.03 | 13-16 | 0.8-1.5 |

304 | ≤0.08 | ≤0.75 | ≤2.0 | ≤0.045 | ≤0.03 | 18-19 | 8-10 |

316 | ≤0.08 | ≤1.00 | ≤2.0 | ≤0.035 | ≤0.03 | 10-14 | 16.0-18.5 |

430 | ≤0.12 | ≤0.75 | ≤2.0 | ≤0.04 | ≤0.03 | 16-18 | ≤0.6 |

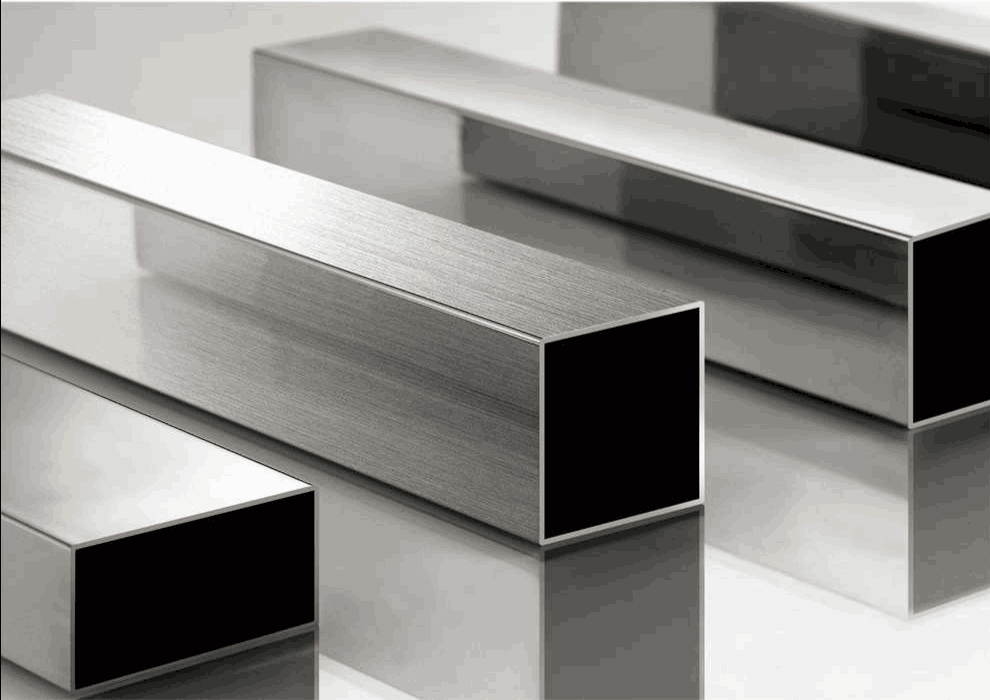

Square pipe and rectangle pipe

round pipe

PACK & DELIVERY

Packaging & Delivery of ss201stainless steel tubes price per kg

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

COMPANY INFORMATION

Company Information

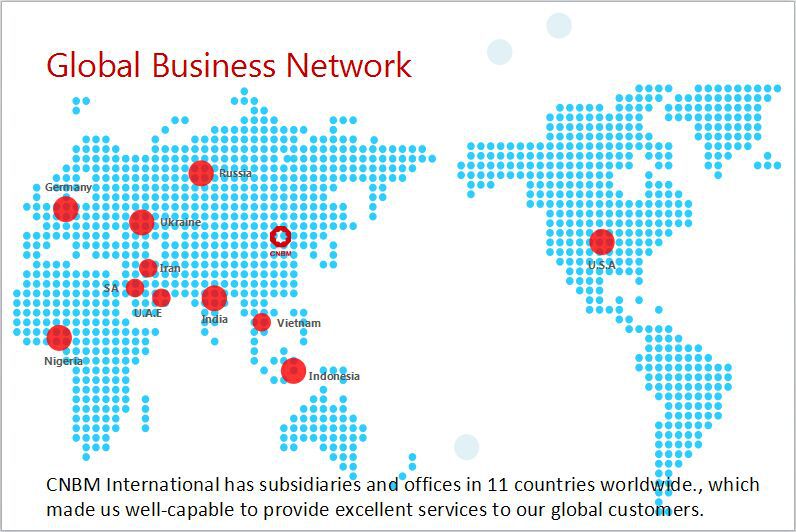

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

Client

Export Markets Our target market is the international market. Every year we export most of products to countries like India, Pakistan, South Korea, Brazil, Australia, South Africa, Spain, Sri Lanka, Taiwan, Hong Kong, etc.

F A Q

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:Why does the 304 stainless steel pipe leak?

- This is the mechanism of pitting ion in neutral solution, such as the effect of chlorine ion on the surface of the passivation film, surface damage, and pitting, uneven part of the organization, the structure of the metal inclusions easily become a source of pittingOf course, there are many other forms of corrosion on austenitic stainless steel, such as crevice corrosion, stress corrosion, and so on.

- Q:What is the cost difference between stainless steel pipes and other materials?

- The cost difference between stainless steel pipes and other materials can vary depending on various factors such as the type of material being compared, the size and specifications of the pipes, and the current market conditions. In general, stainless steel pipes tend to be more expensive than other materials such as PVC, copper, or galvanized steel. This is primarily due to the higher production and raw material costs associated with stainless steel, as well as its superior qualities and durability. Stainless steel pipes offer numerous advantages over other materials, including excellent corrosion resistance, high strength, and the ability to withstand extreme temperatures. These qualities make stainless steel pipes ideal for various applications, especially in industries such as oil and gas, chemical processing, and water treatment. While stainless steel pipes may have a higher upfront cost, they often provide long-term cost savings due to their extended lifespan and reduced maintenance requirements. Additionally, the higher initial investment in stainless steel pipes can be justified by considering the potential costs associated with pipe failures, leaks, or replacements that may occur with other materials. It is important to note that the cost difference between stainless steel pipes and other materials can vary significantly depending on the specific project requirements and market conditions. Therefore, it is advisable to consult with suppliers, contractors, or industry professionals to obtain accurate and up-to-date pricing information for a specific application.

- Q:What are the common joining methods for stainless steel pipes?

- The common joining methods for stainless steel pipes include welding, threaded connections, and flanged connections. Welding is the most common and widely used method for joining stainless steel pipes. It involves melting the ends of the pipes and fusing them together using a welding electrode. The weld can be made using various types of welding techniques such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or Stick welding, depending on the specific requirements of the application. Threaded connections are another popular joining method for stainless steel pipes, especially for smaller diameter pipes. This method involves threading the ends of the pipes and using threaded fittings to connect them. Threaded connections provide a secure and leak-proof joint, and they are relatively easy to install and disassemble when necessary. Flanged connections are used for larger diameter stainless steel pipes or when there is a need for easy disassembly and reassembly. This method involves attaching flanges to the ends of the pipes and connecting them using bolts and gaskets. Flanged connections provide a rigid and reliable joint, and they are commonly used in industrial applications where frequent maintenance or replacement is required. It is important to note that the choice of joining method for stainless steel pipes depends on various factors such as the pipe diameter, pressure and temperature requirements, accessibility, and the specific application. Consulting with a qualified engineer or professional is recommended to ensure the most appropriate joining method is selected for a specific project.

- Q:What is the difference between Sch 40 and Sch 80 stainless steel pipes?

- Sch 40 and Sch 80 stainless steel pipes differ in their wall thicknesses. Sch 40 denotes a pipe with a "Schedule 40" wall thickness, while Sch 80 refers to a pipe with a "Schedule 80" wall thickness. The schedule number signifies the approximate wall thickness of the pipe, with higher numbers indicating thicker walls. When it comes to stainless steel pipes, Sch 80 has a greater wall thickness compared to Sch 40. The variation in wall thickness leads to disparities in pressure rating and strength. Sch 80 stainless steel pipes are engineered to withstand higher pressure and are generally employed in applications where the pipe must endure heightened levels of stress or extreme conditions. Conversely, Sch 40 stainless steel pipes are typically used in less demanding situations where lower pressure ratings are acceptable. Furthermore, the increased wall thickness of Sch 80 pipes results in a smaller internal diameter in contrast to Sch 40 pipes. This reduction in internal diameter can affect the flow rate of fluids or gases through the pipe, so it is crucial to take this factor into account when selecting the appropriate pipe for a specific application. To summarize, the primary distinction between Sch 40 and Sch 80 stainless steel pipes lies in their wall thickness. Sch 80 pipes are thicker and capable of handling higher pressure and stress levels.

- Q:Can magnets attract stainless steel tubes?

- Stainless steel is becoming more and more popular because of its beautiful appearance, corrosion resistance and not easy to damage. More and more pots, city sculpture, architecture, decoration room etc. the use of stainless steel, stainless steel on discrimination but people do not know, some customers buy stainless steel kitchenware, stainless steel utensils with magnets in to try to try. It is stainless steel that attracts the magnet, but stainless steel can not be sucked. It seems that there is a misunderstanding about stainless steel.

- Q:Can stainless steel pipes be used for gas applications?

- Yes, stainless steel pipes can be used for gas applications. Stainless steel is highly resistant to corrosion and can withstand high temperatures, making it a suitable material for transporting gases. Additionally, stainless steel pipes have excellent strength and durability, ensuring the safety and reliability of the gas system. They are commonly used in industrial, commercial, and residential applications where gas is being transported. However, it is essential to ensure that the stainless steel pipes being used meet the specific requirements and standards for gas applications to ensure proper installation and performance.

- Q:Can stainless steel pipes be used for underground water supply lines?

- Yes, stainless steel pipes can be used for underground water supply lines. Stainless steel is highly resistant to corrosion, making it a suitable choice for underground applications where the pipes may come in contact with soil and water. Additionally, stainless steel pipes have excellent strength and durability, ensuring long-lasting performance in underground water supply systems.

- Q:Can stainless steel pipes be used for agricultural irrigation systems?

- Yes, stainless steel pipes can be used for agricultural irrigation systems. Stainless steel is known for its durability, corrosion resistance, and ability to withstand harsh environmental conditions, making it a suitable choice for agricultural applications where long-term performance is required.

- Q:What is the difference between seamless and electric resistance welded stainless steel pipes?

- Seamless and electric resistance welded (ERW) stainless steel pipes are two different methods of manufacturing stainless steel pipes, and they differ in terms of their production process and the characteristics of the resulting pipes. Seamless stainless steel pipes are manufactured through a process called hot rolling or cold drawing, where a solid cylindrical billet or ingot is heated and then pierced to form a hollow tube. This tube is then further elongated and reduced in diameter through several processes to achieve the desired size and thickness. The absence of any welding seam in seamless pipes provides them with a higher level of strength, corrosion resistance, and pressure resistance compared to welded pipes. Seamless pipes are often used in high-pressure applications, as they can withstand higher levels of stress and are less susceptible to leaks or failures. On the other hand, electric resistance welded stainless steel pipes are produced by applying heat and pressure to longitudinally welded stainless steel strips or plates. The edges of the strip or plate are heated and fused together under pressure to form a tube. ERW pipes have a visible welded seam along their length, which is a result of the welding process. While the welded seam may slightly reduce the overall strength and corrosion resistance of the pipe, ERW pipes are still highly durable and suitable for a wide range of applications. They are commonly used in industries such as oil and gas, petrochemical, and plumbing. In summary, the main difference between seamless and electric resistance welded stainless steel pipes lies in their manufacturing process and the presence of a visible welded seam. Seamless pipes are produced without any welding, offering superior strength and corrosion resistance, especially in high-pressure applications. On the other hand, ERW pipes are formed through welding, resulting in a visible seam, but they still possess good durability and are widely used in various industries.

- Q:Can stainless steel pipes handle extreme weather conditions?

- Stainless steel pipes are renowned for their exceptional durability and ability to withstand the harshest weather conditions. They exhibit remarkable resistance to extreme temperatures, heavy rainfall, fierce winds, and even harsh chemicals, remaining corrosion-free and undeteriorated. The inherent qualities of stainless steel, including its superior strength, resistance to corrosion, and tolerance to heat, render it an optimal choice for outdoor applications and adverse weather circumstances. Stainless steel pipes effectively endure intense heat and cold, while effectively combating the detrimental effects of UV radiation and oxidation. These pipes find extensive use in industries encompassing oil and gas, chemical processing, construction, and marine applications, where they confront formidable environments. All in all, stainless steel pipes offer a dependable and enduring solution for handling the most severe weather conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SS 201 Stainless Steel Pipe Price Per Kg

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords