Self-restrained Joint Ductile Iron Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 300000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Overview of Ductile Iron Pipe

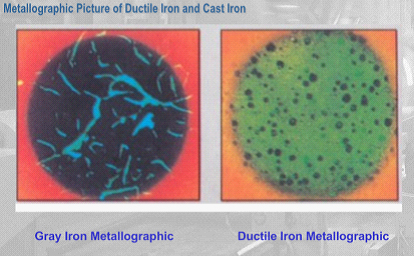

Ductile cast iron, also called ductile iron, spheroidal graphite iron, or nodular cast iron, is a type of cast iron invented in 1943. While most varieties of cast iron are brittle, ductile cast iron is much more flexible and elastic, due to its nodular graphite inclusions.

Graphite particles exist in the form of sphericity in ductile cast iron. Sizes graphite particle are restricted to 6 -7 class and spheroidizing rate should not be less than 80%. Thus after the spheroidizing process, ductile iron will be endowed with mechanical properties of both cast iron and steel.

Much of the production of ductile iron is in the form of ductile cast iron pipe, used for water supply and sewerage design. Ductile cast iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethylene or steel. Ductile Iron Pipe is the most widely-used pipeline product in water supply and water drain/sewage projects.

General introduction of Self-restrained Joint Ductile Iron Pipe

•Material : Ductile Cast Iron

•Size Range : DN 80mm to DN 1200mm

•Unit Effective Length : 6m or 5.7m or negotiable

•Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

•Annual capacity : 300,000 tons

•Coating Exterior: Zinc 130g/m2 according to ISO 8179-1 and bitumen coating 70 microns.

•Cement Interior: Portland Cement/ High Alumina Cement/ Sulphate Resisting Cement Lining according to ISO 4179

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Mechanical Properties

|

Item |

Tensile Strength (N/mm2) |

Elongation(%) |

Proof Stress (N/mm2) |

Hardness HB | ||

|

DN80 TO DN2600 |

DN80 TO DN1000 |

DN1100 TO DN2000 |

DN80 TO DN1000 |

DN100 TO DN2000 | ||

|

Pipe |

≥420 |

≥10 |

≥7 |

≥270 |

≥300 |

≤230 |

|

Fittings |

≥420 |

≥5 |

≥300 |

≤250 | ||

Standard Lining and Coating

External Protection

Metallic zinc complying with the standard ISO8179,and bitumen,or special protective coating according to the customer’s requirement.

Notes:

. Pipes and fittings conform to the requirements of International Standard ISO 2531,British Eurpean Standard BS

. EN545,and their extensions. If information given in English and Chinese differs,the English version prevails.

. Dimensions and masses of pipes and fittings are approximate and are for refererces only;accurate dimensions and

. masses should be confirmed with us at the time of placing order. Flanged joint pipes and fittings are generally

. available with PN10,PN16 and PN25. Socketed joint pipes and fittings generally available with T type and K type joints.

Features of Self-restrained Joint Ductile Iron Pipe:

. Ductile Iron Pipe offers proven reliability and the quality.

. It is quick and easy installation.

. The ductile iron pipe has high pressure capability.

Application:

Used for water and sewer lines.

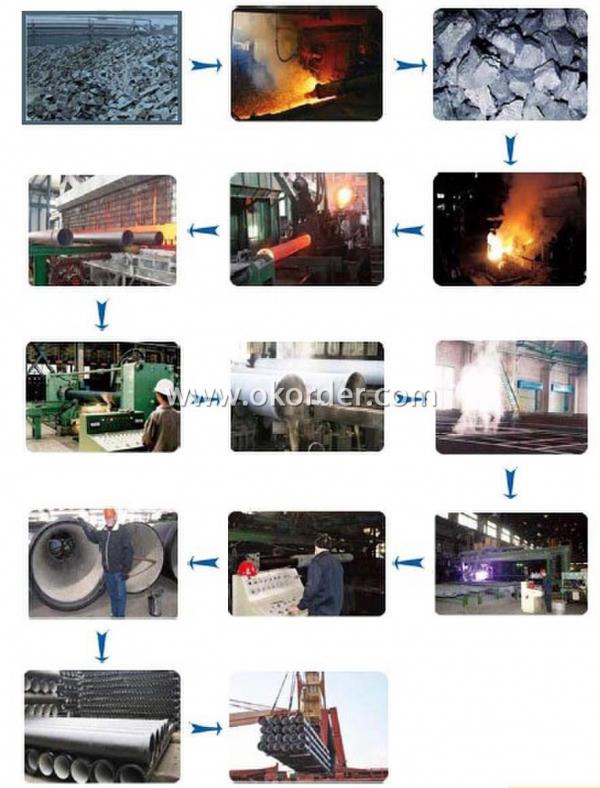

Production Process

Much of the production of ductile iron is in the form of ductile cast iron pipe, used for water supply and sewerage design. Ductile iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethylene or steel.

Specification of Self-restrained Joint Ductile Iron Pipe:

Standard wall thickness of Self-restrained Joint Ductile Iron Pipe

|

Nominal Diameter |

Wall Thickness(mm) | ||||||

|

DN(mm) |

Pipe |

Fittings | |||||

|

Class C |

K8 |

K9 |

K10 |

K12 |

K12 |

K14 | |

|

80 |

4.4 |

6 |

6.0 |

7 |

8.1 | ||

|

100 |

4.4 |

6.0 |

7.2 |

8.4 | |||

|

125 |

4.5 |

6.3 |

7.5 |

8.8 | |||

|

150 |

4.5 |

6.3 |

7.8 |

9.1 | |||

|

200 |

4.7 |

6.3 |

8.4 |

9.8 | |||

|

250 |

5.5 |

6.8 |

7.5 |

9 |

9 |

10.5 | |

|

300 |

6.2 |

6.4 |

7.2 |

8 |

9.6 |

9.6 |

11.2 |

|

350 |

6.3 |

6.8 |

7.7 |

8.5 |

10.2 |

10.2 |

11.9 |

|

400 |

6.5 |

7.2 |

8.1 |

9 |

10.8 |

10.8 |

12.6 |

|

450 |

6.9 |

7.6 |

8.6 |

9.5 |

11.4 |

11.4 |

13.3 |

|

500 |

7.5 |

8 |

9 |

10 |

12 |

12 |

14 |

|

600 |

8.7 |

8.8 |

9.9 |

11 |

13.2 |

13.2 |

15.4 |

|

700 |

8.6 |

9.6 |

10.8 |

12 |

14.4 |

14.4 |

16.8 |

|

800 |

9.6 |

10.4 |

11.7 |

13 |

15.6 |

15.6 |

18.2 |

|

900 |

11.6 |

11.2 |

12.6 |

14 |

16.8 |

16.8 |

19.6 |

|

1000 |

12.6 |

12 |

13.5 |

15 |

18 |

18 |

21 |

|

1200 |

13.6 |

13.6 |

15.3 |

17 |

20.4 |

20.4 |

22.8 |

|

1400 |

15.7 |

15.2 |

17.1 |

19 |

22.8 |

22.8 |

26.6 |

|

1500 |

16.7 |

16 |

18 |

20 |

24 |

24 |

31 |

|

1600 |

17.7 |

16.8 |

18.9 |

21 |

25.2 |

25.2 |

29.4 |

|

1800 |

19.7 |

18.4 |

20.7 |

23 |

27.6 |

27.6 |

32.2 |

|

2000 |

21.8 |

20 |

22.5 |

25 |

30 |

30 |

35 |

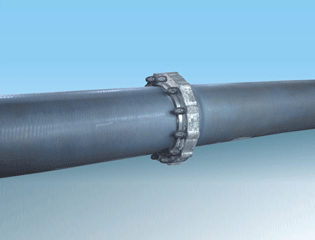

Self-restrained Joint

Self-restrained Type is a push-in self anchored joint. The principle of joint anchoring consists in transmitting the axial forces from one pipeline to the following one, thus ensuring that the joint does not come apart.

The application of self-restrained joints is of particular interest where congested conditions preclude concrete anchor block constructions or in poorly cohesive soils.Self-restrained joints combine the advantages of flexible joint pipes and welded joint pipes.

Photo of Self-restrained Joint Ductile Iron Pipe

- Q:What are the advantages and disadvantages of spheroidal graphite cast iron?

- Compared with cast iron, ductile iron has an absolute advantage in strength. The tensile strength of ductile iron is 60K, while the tensile strength of cast iron is only 31k. The yield strength of ductile iron is 40K, while the cast iron does not show yield strength, and eventually breaks. The strength to cost ratio of ductile iron is far superior to that of cast iron.

- Q:How are ductile iron pipes protected against abrasion or wear?

- Various methods and protective coatings are utilized to protect ductile iron pipes against abrasion or wear. One commonly employed method involves the application of cement mortar lining on the inner surface of the pipe. This creates a smooth and durable layer that effectively resists the damaging effects of flowing water and other substances passing through the pipe. Furthermore, external protection for ductile iron pipes can be achieved by applying a bituminous or epoxy coating. These coatings act as a barrier, safeguarding against external factors like soil or chemicals that may lead to wear or corrosion. By serving as a protective layer, they prevent direct contact between the iron pipe and the surrounding environment. Moreover, in areas where severe abrasion or wear conditions are prevalent, special linings or coatings can be applied. Polyethylene encasement or polyurethane lining can be utilized to provide enhanced protection against abrasion, especially in regions where the pipe is exposed to high turbulence or abrasive materials. In certain cases, ductile iron pipes can also be reinforced with additional materials such as fiberglass or steel wire to increase their resistance to abrasion or wear. These reinforcements offer an extra layer of protection, strengthening the pipe and reducing the likelihood of damage. Overall, ductile iron pipes are designed with a combination of protective measures to ensure their durability and resistance to abrasion or wear. These measures encompass cement mortar linings, protective coatings, special linings or coatings for severe conditions, and reinforcements. These protective methods play a crucial role in prolonging the lifespan of the pipes and maintaining their functionality even in challenging environments.

- Q:Can ductile iron pipes be used for both water and sewer applications?

- Yes, ductile iron pipes can be used for both water and sewer applications. Ductile iron pipes are highly durable and have excellent resistance to corrosion, making them suitable for carrying both potable water and wastewater. They can withstand high pressure and are resistant to external loads, making them ideal for underground installations. Additionally, ductile iron pipes have a long service life and require minimal maintenance, making them a cost-effective choice for both water and sewer systems.

- Q:Are ductile iron pipes resistant to abrasion?

- Yes, ductile iron pipes are resistant to abrasion. Ductile iron is a type of cast iron that has been treated with magnesium to improve its strength and ductility. This makes it highly resistant to wear and tear, including abrasion. Ductile iron pipes are commonly used in applications where they may come into contact with abrasive materials such as sand, gravel, or other particles in the flow. The material's ability to withstand abrasion helps ensure its long-term durability and reliability in various industries, including water distribution, sewer systems, and industrial pipelines.

- Q:How are ductile iron pipes restrained against axial thrust forces?

- Ductile iron pipes are typically restrained against axial thrust forces through the use of various mechanical joint systems. These joints, such as the push-on joint or the restrained joint, provide a secure connection between the pipes, preventing movement and ensuring structural integrity. Additionally, methods like concrete thrust blocks or anchor blocks are often used to further restrain the pipes and counteract any axial thrust forces that may be exerted on them.

- Q:Can ductile iron pipe be used for irrigation systems?

- Yes, ductile iron pipe can be used for irrigation systems. Ductile iron is a strong and durable material that can withstand the high pressure and constant flow of water required for irrigation systems. It is resistant to corrosion, making it suitable for underground applications where it may come into contact with moisture and soil. Additionally, ductile iron pipes have the advantage of being able to handle heavy loads, which is important for irrigation systems that may require the use of heavy machinery or vehicles. Overall, ductile iron pipe is a reliable and long-lasting choice for irrigation systems.

- Q:What are the advantages of cast iron pipes?

- The cast iron pipe has good sealing performance and is not easy to leak. It can reduce the leakage rate of the pipe network and reduce the daily maintenance cost of the pipe network

- Q:Are ductile iron pipes suitable for installation in areas with high groundwater contamination and soil erosion?

- Ductile iron pipes are generally suitable for installation in areas with high groundwater contamination and soil erosion. This is because ductile iron pipes are known for their durability, strength, and resistance to corrosion. They have excellent resistance to acidic and alkaline soils, making them suitable for areas with high groundwater contamination. Furthermore, ductile iron pipes have a high resistance to soil erosion due to their robust construction. They are designed to withstand various external forces, including pressure from the surrounding soil and potential movement caused by erosion. This makes them a reliable choice for installation in areas prone to soil erosion. However, it is important to note that while ductile iron pipes can withstand high groundwater contamination and soil erosion, proper installation techniques and maintenance practices should be followed to ensure their longevity and optimal performance. Regular inspections, proper backfilling, and appropriate protective coatings should be employed to maximize the pipe's lifespan. In conclusion, ductile iron pipes are generally suitable for installation in areas with high groundwater contamination and soil erosion. Their durability, strength, resistance to corrosion, and high resistance to soil erosion make them a reliable choice for such environments. However, it is crucial to follow proper installation and maintenance practices to ensure their longevity and optimal performance.

- Q:What are the different sizes available for ductile iron pipe?

- Ductile iron pipes come in a wide variety of sizes to meet the needs of different applications in the water and wastewater industry. These pipes typically range in diameter from 3 inches to 64 inches. The most commonly used sizes are 4 inches, 6 inches, 8 inches, 10 inches, 12 inches, 16 inches, 20 inches, 24 inches, 30 inches, and 36 inches. However, larger sizes can also be manufactured for specific project requirements. Having different sizes available allows for flexibility in designing and constructing water distribution systems, sewage networks, and other infrastructure projects. The choice of the appropriate size depends on factors like the volume of flow, pressure requirements, and the distance the pipe needs to cover. It's important to note that the size of a ductile iron pipe refers to its internal diameter, which is also known as the nominal bore. The actual outside diameter of the pipe may vary slightly depending on the manufacturer and the specific dimensions provided. When selecting a size for ductile iron pipes, it's crucial to consider factors such as hydraulic capacity, installation requirements, and compatibility with other pipeline components. Seeking advice from engineers and industry experts is recommended to ensure the correct size is chosen for each particular application.

- Q:How to choose a ductile cast iron pipe with guaranteed quality

- Cutting testing: iron filing resistance, filing issued a "Shua" sound, little sticky file, debris was gray with a small amount of white spot, look at the particles of different size, with small particles of fine powder, finger milling, it is easy to make fingers black. Ductile iron filing: when the resistance ratio of gray iron is slightly larger, there are obvious "Shua" sound ", little sticky file, debris was gray with fine bright particles ranging in size but with large particles, with finger milling chips, can be dyed black to gray fingers, but more black the degree of light

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 1958 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East, Africa, South Asia, Eastern Asia |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 3000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b)Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Self-restrained Joint Ductile Iron Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton m.t.

- Supply Capability:

- 300000 Metric Tons per Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords