PVC Waterproof Membrane/PVC Membrane/PVC Roof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproof Membrane Introduction

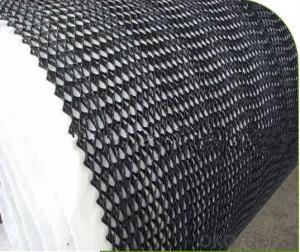

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

PVC Waterproof Membrane Specification

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

If exposed | Exposed, Non-exposed |

Type | Homogeneous, Reinforced with fabric backing |

Color | White/Grey or customized |

PVC Waterproof Membrane Technical Data Sheet

PVC Waterproof Membrane | Standard: GB12952-2011 | ||||||

NO. | Item | Unit | Value | ||||

H | L | P | |||||

1 | Resin Thickness on Middle Mesh ≥ | mm | - | - | 0.4 | ||

2 | Tensile Properties | Max. Strength ≥ | N/cm | - | 120 | 250 | |

Tensile Strength ≥ | Mpa | 10.0 | - | - | |||

Elongation at Max. Strength ≥ | % | - | - | 15 | |||

Breaking Elongation ≥ | % | 200 | 150 | - | |||

3 | Dimensional Stability after Heat Treatment ≤ | % | 2.0 | 1.0 | 0.5 | ||

4 | Foldability at Low Temperature | -25℃ No cracks | |||||

5 | Watertightness | 0.3Mpa, 2h No penetration | |||||

6 | Resistance to Impact | 0.5kg*m, No penetration | |||||

7 | Resistance to Static Loading* | - | - | 20kgs No penetration | |||

8 | Joint Peel Strength≥ | N/mm | 4.0 or membrane broken | 3.0 | |||

9 | Right Angle Tearing Strength≥ | N/mm | 50 | - | - | ||

10 | Trapezoid Tearing Strength≥ | N | - | 150 | 250 | ||

11 | Water Absorption (70℃, 168h) | After immersing≤ | % | 4.0 | |||

After drying≥ | % | -0.40 | |||||

12 | Aging in Hot Weather (80℃) | Time | 672h | ||||

Appearance | No bubbles, cracks, layering, sticky,holes | ||||||

Max. Tensile Retention Rate ≥ | % | - | 85 | 85 | |||

Tensile Strength Retention Rate ≥ | % | 85 | - | - | |||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 80 | |||

Breaking elongation Retention rate≥ | % | 80 | 80 | - | |||

Low Temperature Flexibility | -20℃ No cracks | ||||||

13 | Chemical resistance

| Appearance | No bubbles, cracks, layering, sticky, holes | ||||

Max. Tensile Retention Rate ≥ | % | - | 85 | 85 | |||

Tensile Strength Retention Rate ≥ | % | 85 | - | - | |||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 80 | |||

Breaking elongation Retention rate | % | 80 | 80 | - | |||

Low Temperature Flexibility | -20℃ No cracks | ||||||

14 | Artificial aging* | Time | 1500h* | ||||

Appearance | No bubbles, cracks, layering, sticky, holes | ||||||

Max. Tensile Retention Rate ≥ | % | - | 85 | 85 | |||

Tensile Strength Retention Rate ≥ | % | 85 | - | - | |||

Elongation Retention Rate at Max. Tensile ≥ | % | - | - | 80 | |||

Breaking elongation Retention rate | % | 80 | 80 | - | |||

Low Temperature Flexibility | -20℃ No cracks | ||||||

Remarks: *Resistance to static load is for PVC membranes used on roofing *The time of artificial aging of single-ply roofing membrane is 2500h. *Non-exposed membrane does not require determination of artificial aging. | |||||||

PVC Waterproof Membrane Property

1) Excellent aging resistance.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

PVC Waterproof Membrane Application

--All kinds of roofs, such as steel structure roof, planted roof etc.

--Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

--Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

- Q:Can earthwork products be recycled?

- Yes, earthwork products can be recycled.

- Q:Are earthwork products suitable for road construction?

- Yes, earthwork products such as soil, gravel, and rock are frequently used in road construction. These materials are often used as the base or sub-base layers of roads to provide stability, strength, and drainage. Additionally, earthwork products can be used for embankments, slopes, and other grading purposes in road construction projects.

- Q:What are the different types of geosynthetic drainage systems for sports fields?

- There are several types of geosynthetic drainage systems commonly used for sports fields. These include geocomposite drains, geonet drains, and geotextile drains. Geocomposite drains are made up of a combination of geotextile and a core material, typically a plastic drainage core, which allows for both water flow and filtration. Geonet drains consist of a three-dimensional mesh-like structure that provides a high flow capacity for water drainage. Geotextile drains, on the other hand, are made entirely of a permeable fabric material that allows water to pass through while preventing soil erosion. Each type of geosynthetic drainage system has its own benefits and is selected based on factors such as field type, soil conditions, and budget.

- Q:How do geocells help in soil stabilization?

- Geocells help in soil stabilization by confining and reinforcing the soil, preventing erosion and improving load-bearing capacity. The interconnected cells form a grid-like structure that provides stability and support, preventing soil movement and maintaining its integrity. Additionally, the cells can be filled with various materials, such as gravel or sand, which further strengthen the soil and enhance its stability.

- Q:How can geopipes be used in underground stormwater retention systems?

- Geopipes can be used in underground stormwater retention systems to effectively collect and transport excess rainwater or runoff from various surfaces. These pipes help in directing the water towards a designated storage area, preventing flooding or waterlogging. The geopipes' perforated design allows water to enter while preventing debris or sediment from clogging the system. This technology enhances the efficiency of stormwater management, reducing the strain on existing drainage systems and helping to replenish groundwater reserves.

- Q:What are the different warranty options available for earthwork products?

- The different warranty options available for earthwork products can vary depending on the manufacturer and the specific product. Some common warranty options may include a limited warranty that covers defects in materials or workmanship for a certain period of time, a structural warranty that guarantees the stability and durability of the product, or a performance warranty that ensures the product will meet certain specifications or standards. It is important to carefully review the warranty terms and conditions provided by the manufacturer before purchasing an earthwork product.

- Q:How are earthwork products different from regular construction materials?

- Earthwork products, such as soil, gravel, and sand, differ from regular construction materials in that they are derived from natural resources found on or beneath the Earth's surface. Unlike regular construction materials like concrete or steel, which are typically manufactured in factories, earthwork products are obtained through excavation or mining processes. Additionally, earthwork products are often used as foundational materials for construction projects, providing stability, drainage, and support to structures, whereas regular construction materials are typically used for above-ground construction elements.

- Q:What is the lifespan of geocomposite drainage systems?

- The lifespan of geocomposite drainage systems can vary depending on various factors such as the quality of materials used, installation techniques, and environmental conditions. However, on average, geocomposite drainage systems can last anywhere from 20 to 50 years.

- Q:Can earthwork products be used in underground storage applications?

- Yes, earthwork products can be used in underground storage applications. These products, such as geotextiles and geosynthetics, are commonly used to reinforce and stabilize the ground in underground storage facilities, providing additional strength and durability to the structure. They help prevent soil erosion, improve drainage, and enhance the overall performance and lifespan of the underground storage system.

- Q:What are the different types of geosynthetic drainage systems?

- There are several types of geosynthetic drainage systems, including geocomposite drains, geonets, geotextile drains, and geospacers. These systems are used to effectively drain water and prevent the buildup of excess moisture in various applications such as roads, landfills, retaining walls, and sports fields.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproof Membrane/PVC Membrane/PVC Roof Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords