PET Bottle Preform Mould Supply 48 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

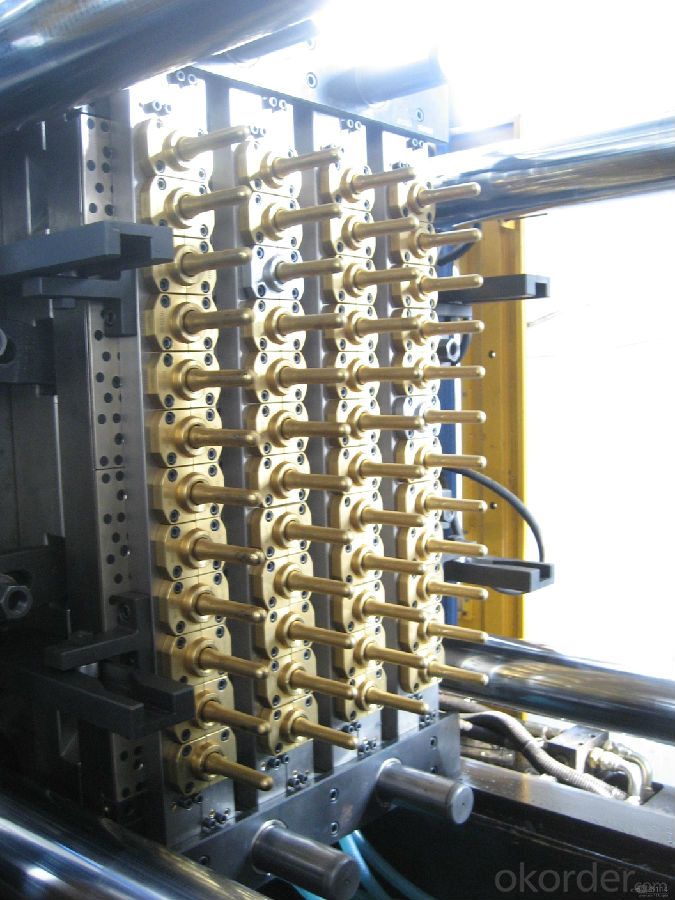

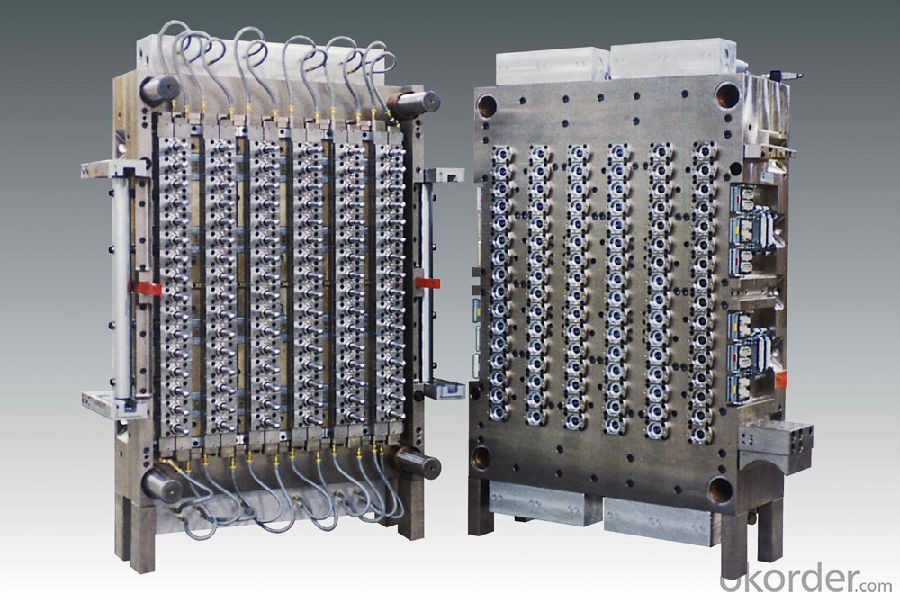

1. Structure of Multi-Cavities PP Preform Mould

preform mould,PET preform mould

single cavity with self-lock to keep less thickness tolerance

Mould life:800K-1,500,000 shots

PET preform mould

2. Main Features of Multi-Cavities PP Preform Mould

.Mould structure

Advanced structure is designed to improve rate of finished products;Two-step double taper locating technology;The each cavity is self locked independently with the core.The off-center adjustment system make the perform thickness error less than 0.05mm.Bottleneck is adopted International Screw thread standard, No cutting of gate to reduce the labor intensity

. Material of steel

Cavity and core use stainless steel 2316 with fine polishing,high hardness to get mold's high precision and good quality. mechanical treatment cavity and core to prolong service life,nitrogen treatment with neck screw.with fitly operation,guarantee Long using life over 2 million shots of injection cycle

.About gate system

Pin-valve gate,pneumatic drive the nozzle pin simultaneous high speed open and close action. which can effectively control the injection hole open and close actions on each cavity. reliable seal function, smooth moving, low thermal expansion rate ,long using life and also saves electric energy.

.About hot runner

The hot runner system is designed and made by ourselves, it can achieve ideal and prompt heating effect for preform production ,cavity with lower injection pressure to reduce wear and tear of mould parts.we use the double heating system,it has separate temperature control mode ,the heat bar are used to heat the mould mainfold plate,small heaters supply the heating temperature for cavity nozzle continuously.

.Cooling system

Each parts including core ,cavity and valve gate has independently cooling system.

.special satisfied servive

Each mould undergoes strict mould test before delivery.we can provide an experienced team for installation and test as per client's request Standard inter-changeable mould components

3. Images of Multi-Cavities PP Preform Mould

4. Packaging & Shipping of Multi-Cavities PP Preform Mould

The company can provide full no-man bottle preform product line, which includes injection machine, mould robotic arm and moulds.

5. FAQ of Multi-Cavities PP Preform Mould

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What’s your MOQ?

A: The MOQ depends on the design and production processes of the products. For the majority of our bathroom sets, our MOQ is 10000sets.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

Q:How long can I receive an order?

A: That depends on the specific items and your order quantity. Normally, the lead time for a 20ft container load is 50-60 days.

- Q:There are several types of mould

- Rubber mold: it is divided into pressing mould, injection molding and extrusion molding. The processing of rubber. Glass: it is divided into press and die. Processing glass. Casting mould: it is divided into sand mold, shell mold, lost wax mould, pressure casting mould and metal mold. Process melt alloy.

- Q:The effect of mould preheating and several methods of preheating

- In order to protect the mould and improve the efficiency of the mould, it is necessary to keep the mould working in a certain temperature range as much as possible. If the mould no preheating, on the other hand, due to the mold temperature is low, it is easy to cause molding difficult, mucous membrane, the casting defects such as cracks, on the other hand, due to the mold temperature change is too big, hot and cold stress is very big, it is easy to mold damage, severe cases, may cause mould crack. Therefore, pre-heating is very important. According to the heating method, it can be divided into electric heating, natural (coal) gas heating and temperature heating. 1) electric heating: the heat tube is mainly heated by heat tube, which is clean and convenient to use. The drawback is that the thermal radiation is small. Die casting die is not adopted normally.

- Q:The function of die water board?

- The structure of the nozzle is mainly used for the inlet of the gate.

- Q:The wall thickness of the die is affected by the plastic parts

- For thermoplastic materials, the cooling time is added For thermosetting materials, solidification is not complete.

- Q:What is the top and bottom die in the mould?

- Generally speaking, the upper and lower mould is in punching machine, casting machine, hydraulic press is the most common, and in this case, the upper die also called dynamic model, the model is called a static mode, this is because, when opening the die was mechanical drive dynamic model, complete open mold, so, in the upper die and lower die.

- Q:How many types of molds? Please help me out!

- The mold can be divided into metal mould and non-metallic mould according to the material that is formed. The metal mould is divided into: casting mould (non-ferrous metal casting, steel casting) and forging die etc. Non-metallic mold is also divided into: plastic mould and inorganic non-metallic mould. And according to the material of the mould itself, the mold can be divided into: sand mold, metal mould, vacuum mold, paraffin mold and so on. With the rapid development of polymer plastics, plastic mould is closely related to people's life. Plastic mould can be divided into: injection molding mold, extrusion molding mold, gas auxiliary molding mould and so on.

- Q:What does it mean to have a rough die

- The tool is used to process the rough shape of the mould. And the machine tool and cutter that open coarse use is less accurate, such processing speed is relatively quick. It needs to be left with a residual amount, and then replaced with a processed machine tool and tool. Die strategy: Follow the perimeter: less knife, more clean blade, more empty blade, suitable for electrode processing, avoiding the phenomenon of the cutting of the knife in electrode processing. Follow the workpiece: it is not easy to cut, the way is safe, it is suitable for steel material processing, lifting the knife.

- Q:What is the main meaning of die mold?

- It is the fractal type, which is to divide the mold into the upper and lower, the block, the living block. That is to say that the product is split into a cavity to make the mold.

- Q:What is the use of the mold collecting water

- The large molds that have more water in general need to be more than a dozen or even hundreds of water from the molds. There are not so many interfaces in the cooling water. Only the water that was first placed on the mold will be concentrated on the water block, and then from the water block to the cooling water.

- Q:Is there any way to keep the ice from sticking to the mold and remove it from the mold

- In the hot water under the mould, soon the edge of the ice melts and buckles.After freezing, soak the die in the water and pull.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PET Bottle Preform Mould Supply 48 Cavity

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords