Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Light Steel Frame Formwork with Plastic Plywood

Light steel frame formwork is constructed with two different plywood as frames-wood plywood and plastic plywood. The light frame formwork with Plastic plywood more and more popular in construction industry.

2. Main Features of Light Steel Frame Formwork with Plastic Plywood

-High quality of plastic plywood can stay solid with more than 7 hours in boiled water.

-Frame of plywood is made of plastic as well

-Repeated use of more than 20 times

-PP material used

-Plywood is used inside

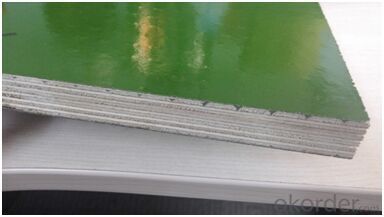

3. Light Steel Frame Formwork with Plastic plywood images

4. Light Steel Frame Formwork Specifications

5. FAQ of Light Steel Frame Formwork with Plastic plywood

1) What can we do for you?

.We can ensure the quality of the Light Steel Frame Formwork with Plastic Plywood and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: wood package and adhesive tape

.Shipping: by sea

Shipping time: Normally small orders, it just1week business days to arrive your hand; When comes to the customs declaration, it may need 2weeks.

- Q:Are there any specific code or regulatory requirements for using steel frame formwork?

- Yes, there are specific code and regulatory requirements for using steel frame formwork in construction projects. These requirements may vary depending on the country and region, as different jurisdictions have their own building codes and regulations. In general, steel frame formwork systems must comply with structural design standards and codes that ensure the safety and integrity of the structures being built. These codes typically cover aspects such as load-bearing capacities, stability, and durability of the formwork system. For instance, in the United States, the American Concrete Institute (ACI) provides guidelines and standards for formwork design and construction. ACI 347R-14, "Guide to Formwork for Concrete," offers recommendations for steel formwork systems, including criteria for strength, stability, and dimensional tolerances. Similarly, the European Union has its own set of regulations and standards for formwork systems. The European Standard EN 12812:2008, "Falsework - Performance requirements and general design," specifies the requirements for steel formwork, including aspects such as load-bearing capacity, safety factors, and material properties. It is essential for contractors and designers to comply with these code and regulatory requirements when using steel frame formwork in construction projects to ensure the safety of workers and the structural integrity of the final building. Failure to adhere to these requirements may lead to accidents, structural failures, or non-compliance with building regulations, resulting in legal consequences and potential liability. Therefore, it is crucial to consult the relevant building codes and regulations in the specific jurisdiction where the construction is taking place to ensure compliance with the specific requirements for steel frame formwork.

- Q:How does steel frame formwork help in achieving accurate concrete alignment?

- The technique of steel frame formwork involves the utilization of steel frames to hold the concrete in place until it becomes solid. Due to various factors, this approach is highly efficient in achieving precise alignment of the concrete. To begin with, the steel frame formwork provides a sturdy and inflexible structure that securely holds the concrete during the pouring and setting stages. The steel frames are designed to endure the pressure and weight of the wet concrete, preventing any movement or deformation. This stability allows for the concrete to be poured accurately, resulting in precise alignment. Moreover, the steel frame formwork is adjustable and customizable. The frames can be easily modified and aligned to fit the desired shape and dimensions of the concrete structure. This flexibility enables construction workers to achieve accurate alignment by making precise adjustments to match the intended design. In addition, the use of steel frame formwork ensures tight joints and connections between different sections of the formwork. This tightness guarantees the absence of gaps or spaces, preventing the concrete from leaking or deviating from the desired alignment. The precise joints and connections also contribute to the overall accuracy of the concrete alignment. Furthermore, the steel frame formwork provides a smooth surface for pouring the concrete. The smoothness of the steel frames aids in achieving a uniform and level finish by reducing the possibility of irregularities or bumps on the surface. This smooth surface allows the concrete to settle evenly, resulting in accurate alignment. In conclusion, the utilization of steel frame formwork is an effective technique for achieving precise concrete alignment. Its sturdy structure, adjustability, tight joints, and smooth surface all contribute to ensuring accurate alignment of the concrete. By employing steel frame formwork, construction projects can attain high levels of accuracy and quality in their concrete structures.

- Q:How does steel frame formwork help in reducing material waste?

- Steel frame formwork helps in reducing material waste by providing a reusable and durable structure for concrete construction. Unlike traditional formwork made of timber or plywood, steel frame formwork can be used multiple times without deteriorating, thus minimizing the need for frequent replacement. This not only reduces the amount of material waste generated but also saves costs associated with purchasing new formwork for each construction project. Additionally, steel frame formwork offers better dimensional accuracy and stability, resulting in less concrete wastage during pouring and better quality construction overall.

- Q:How does steel frame formwork handle different types of concrete additives?

- Steel frame formwork is highly versatile and can easily handle different types of concrete additives. The strength and rigidity of the steel frame provide excellent support and stability, allowing for the incorporation of various additives such as admixtures, fibers, or pigments into the concrete mixture. The steel frame formwork ensures that these additives are evenly distributed throughout the concrete, resulting in enhanced durability, improved workability, and improved aesthetic properties of the final structure.

- Q:How does steel frame formwork handle different types of formwork ties?

- Steel frame formwork, commonly used in a variety of building projects, is a versatile and durable construction system. Its flexibility and adaptability are evident in its ability to handle various types of formwork ties. Formwork ties play a crucial role in the construction process, as they secure the formwork panels together, ensuring structural stability and shape retention during concrete pouring. Steel frame formwork is specifically designed to accommodate different types of formwork ties, such as snap ties, wedge bolts, and coil ties. Snap ties are favored in steel frame formwork due to their ease of use and quick installation. These ties consist of two separate parts that are easily snapped together, creating a strong connection between the formwork panels. Steel frame formwork incorporates snap ties by providing suitable holes or slots in the frame members where the ties can be inserted and secured. Wedge bolts, another type of formwork tie, are also compatible with steel frame formwork. They are inserted through holes in the formwork panels and secured with wedge plates or nuts. Steel frame formwork can be designed with pre-drilled holes or brackets to accommodate wedge bolts, ensuring proper alignment and tightness. Coil ties are used when adjustable formwork ties are required. These ties consist of a coil rod that can be extended or shortened as needed. Steel frame formwork can be designed with dedicated channels or brackets to securely hold coil ties in place. This allows for easy adjustment and repositioning of the formwork ties during the construction process. In summary, steel frame formwork can handle various types of formwork ties by providing suitable provisions such as holes, slots, brackets, or channels. This ensures that the formwork ties can be securely attached to the steel frame formwork, providing the necessary structural support and shape retention during concrete pouring.

- Q:How does steel frame formwork handle different types of concrete curing agents?

- Steel frame formwork proves to be highly compatible and resilient in handling various types of concrete curing agents in the construction industry. These agents, which are crucial for achieving desired concrete strength and durability, include chemical admixtures, curing compounds, water-based curing membranes, and traditional wet curing methods. The inherent properties of steel frame formwork enable it to effectively handle different types of concrete curing agents. Firstly, its high strength and stability allow it to withstand the weight and pressure exerted during the curing process, ensuring the formwork remains intact and provides necessary support to the curing concrete. Secondly, steel's excellent resistance to various chemical substances, including curing agents, makes steel frame formwork highly durable and resistant to deterioration or corrosion when in direct contact with these agents. This ensures long-term usability without being affected by chemical admixtures or curing compounds. Additionally, steel frame formwork is designed for easy cleaning and maintenance, which is particularly important when dealing with curing agents. Thorough cleaning of the steel frames ensures that any residue is removed, preventing it from affecting the quality and appearance of subsequent concrete pours. This guarantees that the formwork remains clean and ready for the next use, regardless of the type of curing agent employed. In conclusion, steel frame formwork is a reliable choice for construction projects requiring the use of curing agents. Its strength, stability, resistance to chemicals, and ease of maintenance enable effective and efficient curing processes, resulting in high-quality concrete structures. Whether it is chemical admixtures, curing compounds, or traditional wet curing methods, steel frame formwork ensures optimal performance.

- Q:How does steel frame formwork handle the placement of decorative elements and finishes within the concrete structure?

- Steel frame formwork is a highly versatile and efficient method of concrete construction that allows for the seamless integration of decorative elements and finishes within the concrete structure. With its rigid and robust structure, steel frame formwork provides a stable platform for the placement of various decorative elements such as architectural features, patterns, textures, and intricate designs. One of the key advantages of steel frame formwork is its ability to accurately replicate complex shapes and contours. This is achieved by using customized steel panels that can be easily adjusted and modified to match the desired design requirements. These panels can be shaped and sized according to the specific dimensions and intricacies of the decorative elements, ensuring a precise and seamless fit within the concrete structure. Moreover, steel frame formwork allows for the incorporation of various finishes into the concrete surface. This can include smooth finishes, exposed aggregate, stamped patterns, or textured surfaces. The steel panels can be designed to accommodate different types of finishes, ensuring that the desired aesthetic outcome is achieved. In addition, steel frame formwork allows for the efficient installation of embedded items such as electrical conduits, pipes, and fixtures. The steel panels can be designed with pre-cut holes or spaces to accommodate these elements, ensuring that they are seamlessly integrated within the concrete structure without compromising the overall design or functionality. Overall, steel frame formwork provides a reliable and flexible solution for handling the placement of decorative elements and finishes within a concrete structure. Its versatility, accuracy, and customization capabilities make it an ideal choice for achieving the desired aesthetic outcome while maintaining the structural integrity of the building.

- Q:What are the different types of connection brackets used with steel frame formwork?

- There are several different types of connection brackets that can be used with steel frame formwork in construction projects. These brackets are essential for securely connecting and supporting the formwork panels and ensuring the stability and strength of the overall structure. Some of the common types of connection brackets used with steel frame formwork include: 1. Wedge brackets: These brackets are commonly used for connecting the vertical and horizontal steel frame members. They have a wedge shape that allows for easy insertion and tightening, ensuring a tight and secure connection. 2. Clip brackets: Clip brackets are often used for connecting the formwork panels to the steel frames. They typically have a spring-loaded clip mechanism that allows for quick and easy attachment and detachment of the panels. This makes them particularly useful for formwork systems that require frequent assembly and disassembly. 3. Bolted brackets: Bolted brackets utilize bolts and nuts to secure the formwork panels to the steel frames. They provide a strong and durable connection but require more time and effort for assembly and disassembly. 4. Hook brackets: Hook brackets are commonly used for connecting the formwork panels to the horizontal steel frame members. They have a hook-shaped design that allows for easy attachment and detachment, providing a quick and efficient connection. 5. Pin brackets: Pin brackets use pins or dowels to connect the formwork panels to the steel frames. They provide a reliable and sturdy connection and are often used in conjunction with other types of brackets for added stability. These are just some of the different types of connection brackets that can be used with steel frame formwork. The choice of bracket will depend on factors such as the specific formwork system being used, the desired level of stability, and the ease of assembly and disassembly required for the project.

- Q:What are the different types of supports used in steel frame formwork systems?

- Steel frame formwork systems utilize various types of supports to ensure stability and safety. These supports include adjustable props, soldier beams, tubular scaffolding, H-beams, props with forkheads, and steel bracing. Adjustable props are vertical steel members that can be easily adjusted to accommodate different heights. They provide stability and support for horizontal formwork elements like beams and slabs. Soldier beams, on the other hand, are horizontal steel members used to support vertical formwork elements such as walls and columns. Placed at regular intervals, they help distribute the load evenly. Tubular scaffolding is a versatile support system comprising steel tubes and couplers. It can be easily assembled and adjusted to provide support for various formwork applications. H-beams, commonly found in large-scale construction projects, offer strong and stable support for vertical formwork elements. Props with forkheads, similar to adjustable props, have a fork-shaped head that effectively supports horizontal formwork elements like beams and slabs. They provide a secure and stable support system. Steel bracing, placed diagonally between vertical and horizontal supports, provides additional support and stability to the formwork system. It prevents any lateral movement. In summary, these different types of supports are essential for maintaining stability and safety in steel frame formwork systems. They ensure the necessary support for formwork elements and facilitate efficient and effective construction processes by distributing the load evenly.

- Q:How does steel frame formwork compare to plastic formwork?

- Steel frame formwork is generally considered to be more durable and long-lasting compared to plastic formwork. It offers higher strength and stability, making it ideal for heavy-duty applications and large-scale construction projects. Steel formwork is also reusable, which reduces the overall cost and waste generated. On the other hand, plastic formwork is lightweight and easier to handle, making it suitable for smaller projects and quick installations. However, it may not withstand heavy loads or harsh weather conditions as well as steel formwork. Ultimately, the choice between steel frame formwork and plastic formwork depends on the specific requirements and scale of the construction project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Frame Formwork with Plastic Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords