injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Condition: New

Type: Tube Head Injection

Style: Horizontal

Brand Name: LOG

Model Number: LOG 250S8

Place of Origin: Zhejiang, China (Mainland)

Plastic Type: Thermoplastic

Automatic: Yes

Injection Weight: 625

Clamping Force: 2500kn

Opening Stroke: 520mm

Power(W): 29kw

Certification: CE

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | 20GP,40GP,40HQ |

|---|---|

| Delivery Detail: | 30 Days |

Product performance and advantages:

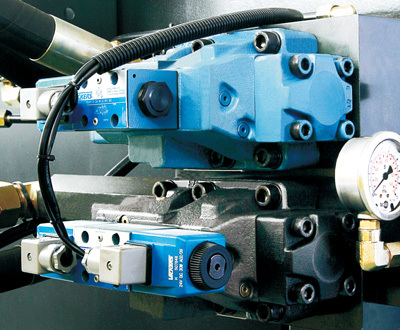

1. Servo energy-saving system

Using the servo motor oil electricity composite structure

2. Servo motor high response feature

It costs only 0.05s for servo energy saving injection molding machines to achieve the maximum output, in comparison with conventional hydraulic injection molding machines. The response speed has been obviously increased, improving the production efficiency.

3. Unique function

Large colored screen with TFT interface

Full automatic close-loop control

Module design of hardware

Auto-tune PID temperature control

Pc interface USB, PIC, and FLASH…

Curve monitoring and analysis function

K-can data transmission (500Kbit/s)

On-line central monitoring function

LOG-250S8 Technical parameters

Description | Unit | LOG-250S8 | ||

international recognized models | 1140/250 | |||

injection | A | B | C | |

Tjeoretical injection volume | cm³ | 510 | 687 | 863 |

Shot volume | g | 464 | 625 | 785 |

Oz | 16.2 | 21.8 | 27.4 | |

Screw diameter | mm | 50 | 58 | 65 |

Injection diameter | mpa | 224 | 166 | 132 |

Screw L:D ratio | 24:1 | 21:1 | 18.7:1 | |

Scerw steoke | mm | 260 | ||

Screw rotate speed | r/min | 0-180 | ||

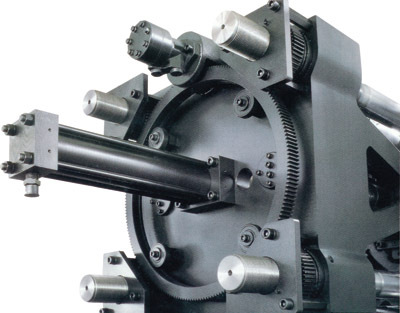

CLAMPING UNIT | ||||

Clamping force | kN | 2500 | ||

Opening stroke | mm | 520 | ||

Platen size | mm*mm | 820*790 | ||

Space between tie bars | mm*mm | 560*530 | ||

Maldthickness | mm | 200-580 | ||

Platen Mix stroke | mm | 1100 | ||

Ejection stroke | mm | 150 | ||

Ejcetion force | kN | 67 | ||

Power/Elcetric Heating | ||||

Hydralic system pressure | Mpa | 17.5 | ||

Pump motor | kw | 29 | ||

Heating power | kw | 16 | ||

Number of temp.conteol | 4+nozzle | |||

Other | ||||

Cycle time | sec | 4.8 | ||

Tank volume | L | 380 | ||

Machine dimesions | m*m*m | 6.2*1.46*2.15 | ||

Weight of machine | kg | 8000 | ||

- Q:when the material stored, the screw has been in situ, and will not go back to the set stop position. What shall I do?

- The storage pressure is too small2. back pressure is too large, leading to the screw can not relax3. hydraulic system pressure relief4. melt temperature is too low5., melt motor power is too small, or the motor pressure is serious.6. screw barrel and raw materials do not match7., the material is not normal?More injection molding machine screw knowledge inquiries, Baidu search: "Jin Xin * screw", "Shenzhen Jin Xin * screw" for you to answer! Hope to adopt!

- Q:When the injection machine is ejected, does the screw screw rotate?

- Do not rotate until the material is rotatedAskThank you. Could you tell me how much the injection is only related to the injection time?Chasing the answerPressure size and time

- Q:What's the meaning of "loosening and retreating" before injection machine?

- Small is relatively loose, loose retreat is to prevent the flow of material out of the back too much air inside, back too little will flow out, under the influence of the quality of the first mock exam.Injection molding machine, also known as injection molding machine or injection machine. It is a thermoplastic or thermosetting plastic plastic molding mold made of plastic products of all shapes of the main molding equipment. It is divided into vertical, horizontal and all electric type. The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q:What's the injection?

- Is the plastic products processing, the use of mold a molding

- Q:Injection back pressure problem

- Two, proper adjustment of the benefits of back pressure1, can melt inside the barrel compaction, increase density, improve the stability of injection quantity, weight and size of the products. 2. The gas in the melt can be extruded to reduce the gas, the inner bubbles and the gloss uniformity of the products. Slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon. 3, slow speed screw back, so that melt inside the barrel full plasticizing, mixing and melting toner, color uniformity, avoid product color mixing phenomenon. 4, appropriately increase the back pressure, can improve the product surface shrinkage and product periphery walk glue situation. 5. It can raise the temperature of molten material, improve the plasticizing quality of melt material, improve the fluidity of melt filling, and no cold glue on the surface of the melt.

- Q:Can you tell me if there are 350 grams of three injection molding machines? How much? Thank you

- Small equipment each company has also ten it this brand is almost a domestic brand quality and sea character generation

- Q:What are the common problems and solving methods of injection molding machine? The more detailed, the better the month

- Non thimbleA, the actual location of the mold is not up to the actual setting;B, computer set no thimble or thimble times zero;C, the set of process parameters are incorrect;Detection status of D and thimble electronic ruler;Mechanical damage of E and ejector pin mechanism;F, the valve out of the direction of the valve is charged and spool work is normal.No needleA, computer process parameters;Detection status of B and electronic ruler;C, the working state of the directional valve.Abnormal movements of the meltA, the temperature of the melt tube is not set;B, the process parameters are unreasonable;Detection status of C and electronic ruler;D, the working state of the directional valve;E, melt into the cylinder with hard objects, stuck screw;Behind F, the barrel does not lead to water transport water, feeding inlet temperature is too high;G, glue back pressure is too large, check back pressure valve;H, adhesive motor or transmission shaft failure;I, hopper no material;The ejection motion is abnormalDetection status of a and electronic ruler;B, the working state of the directional valve;C, speed, pressure, position and time setting of process parameters;D, melt tube or nozzle temperature is not set;E, foreign body stuck in the melt tube;F, nozzle blocked;The G, the firing point and the stop switch do not work.Semi automatic and fully automatic working state is out of orderThe first observation is the problem in which a working condition, and then checked for specific actions, full automatic working condition but also to check the electric eye or time setting.

- Q:What is the back pressure in the injection molding machine?

- Jin Xin offers you:Jin Xin explain the injection molding machine screw back pressure what role?Back pressure allows the screw to produce enough mechanical energy in the rotation of the reset to melt and mix the plastic, and the back pressure has the following uses.The volatile gases, including air, are discharged to the outer cylinder.Mix the additives (e.g., toner, color, antistatic agent, talc, etc.) and melt evenly.Homogenizing the melt flowing through different screw lengths.Providing uniform and stable plasticizing material to obtain accurate weight of finished products.The back pressure can make up the melt temperature of injection molding machine barrel, rise and set pressure value associated with a large injection molding machine, screw diameter more than 70mm [(2.75in) of the oil pressure can be up to 2.5-4MPa], but need to pay attention to the oil pressure is too high, or is caused by the melt pressure back pressure resistance induction high temperature molten material in the barrel is too high, this kind of situation for heat sensitive plastics production is destructive.And too high back pressure also caused excessive screw and irregular offside, so that the amount of plastic is very unstable. The viscoelastic properties of offside and plastic screw the screw; offside and melt the stored energy. The more energy, the greater the offside screw distance, the energy stored in the screw stops rotating, suddenly beat back, some thermoplasticPlastic beating phenomenon is more severe than other plastic, such as LDPE, HDPE, PP, EVA, PP/EPDM composite and PPVC, compared with GPPS, HIPS, POM, PC, PPO - M and PMMA, more prone to beating phenomenon. For optimum production conditions, the correct back pressure setting is critical. Proper back pressure setting allows the mixture to be properly mixed, and the offside range of the screw does not exceed 0.4mm (0.016in).

- Q:How about the four column balance of injection molding machine?

- The injection molding machine heats the plastic, applying high pressure to the molten plastic to make it crack and fill the mold cavity.

- Q:The proportion of each kind of introduction? Molding shrinkage? Molding temperature? Drying conditions? Overall performance? Mainly for use. I sell plastic parts and I want to make a wall calendar.

- PMMA poly methyl methacrylate (PMMA)PC polycarbonatePOM POMTeflon, PFA PTFE (Te Fulong)CN cellulose nitrate (Sai Lulu)Specific technical parameters,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

injection molding machine LOG-250S8/A8 QS Certification

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords