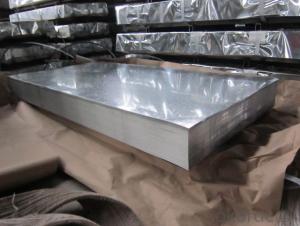

Hot-dipped Galvanized Steel Sheet in Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

Usually we can load 26tons in one 20’FCL container.

- Q:Can the steel sheets be used for skylights or roof windows?

- Certainly, skylights or roof windows can make use of steel sheets. Steel, being a resilient and robust substance, is capable of enduring diverse weather circumstances, thus rendering it appropriate for such purposes. Moreover, steel sheets may be crafted and tailored to satisfy the particular specifications of skylights or roof windows. By installing them, one can avail oneself of both natural light and ventilation while simultaneously upholding the building's structural integrity. However, it is vital to guarantee adequate insulation and glazing in order to avert any heat loss or gain and to maximize energy efficiency.

- Q:What are the different jointing methods for steel sheets?

- There are several different jointing methods that can be used for steel sheets, depending on the specific requirements and applications. Some of the most common jointing methods for steel sheets include: 1. Welding: Welding is one of the most widely used jointing methods for steel sheets. It involves melting the edges of the steel sheets and then joining them together by applying heat and pressure. Different welding techniques, such as arc welding, gas welding, or laser welding, can be used depending on the thickness and type of steel sheets. 2. Bolting: Bolting involves joining steel sheets together using bolts and nuts. This method is commonly used in applications where the joint needs to be easily disassembled or replaced. Bolting provides a strong and secure joint, and it can be used for both permanent and temporary connections. 3. Riveting: Riveting is a jointing method that involves using rivets to join steel sheets together. Rivets are cylindrical metal pins with a head on one end, and they are inserted through holes in the steel sheets. The rivet is then deformed to secure the joint. Riveting is often used in applications where high shear strength is required. 4. Adhesive bonding: Adhesive bonding involves using specialized adhesives to join steel sheets together. This method provides a strong and durable joint, and it is often used in applications where welding or other mechanical jointing methods are not suitable. Adhesive bonding also allows for a more uniform distribution of stress across the joint. 5. Mechanical fasteners: Mechanical fasteners, such as clips, clamps, or brackets, can also be used to join steel sheets together. These fasteners are designed to provide a secure and reliable connection without the need for welding or other permanent jointing methods. Mechanical fasteners are commonly used in applications where ease of assembly and disassembly is required. Overall, the choice of jointing method for steel sheets depends on factors such as the specific application, the desired strength and durability of the joint, and the ease of assembly and disassembly. It is important to carefully consider these factors and select the most appropriate jointing method to ensure a successful and reliable connection.

- Q:Can steel sheets be customized according to specific requirements?

- Yes, steel sheets can be customized to meet specific requirements.

- Q:How do steel sheets perform in terms of thermal conductivity?

- Steel sheets have high thermal conductivity, meaning they are capable of conducting heat efficiently.

- Q:Can steel sheets be used for HVAC applications?

- Indeed, HVAC applications can utilize steel sheets. In the realm of HVAC ductwork construction, steel sheets are frequently employed owing to their robustness, longevity, and fire-resistant qualities. These sheets can be effortlessly molded into diverse configurations and dimensions, tailored to the precise needs of HVAC systems. Moreover, steel sheets exhibit resistance against corrosion, a pivotal attribute in HVAC applications where moisture and condensation may manifest. All in all, steel sheets are a fitting material option for HVAC applications, given their mechanical characteristics and capacity to endure the demands of heating, ventilation, and air conditioning systems.

- Q:What is the average thickness of steel sheets?

- The average thickness of steel sheets varies depending on the specific application and industry. However, common thicknesses range from 0.4 mm to 6 mm for general purposes, while thicker sheets can go up to 25 mm or more for specialized uses.

- Q:What are the driving methods for steel sheet piles?

- Mechanical hand general construction pile length of less than 12m steel pile; more than 12m length generally use crawler crane combined with vibration hammer construction, if the surrounding environment is sensitive to vibration, can use Japanese static pressure pile driving machine construction. The vibration hammer: DZ40 DZ45DZ60 DZ90 DZJ120; ordinary steel sheet pile, DZ60 type vibrating hammer.

- Q:Can steel sheets be used in the medical industry?

- Yes, steel sheets can be used in the medical industry. They are often used in the manufacturing of medical equipment, surgical instruments, and medical furniture due to their durability, corrosion resistance, and ease of sterilization.

- Q:How to choose welding method for welding different plate and thick steel plate?

- How to choose welding method for welding different plate and thick steel plate?:It depends on what process you use welding: manual arc welding, thick plate side should do thinner processing, become 12 thick, that is, a transition ramp, 15 degrees can be reached, two plates corresponding to the edge of the same thickness. V shaped groove, single side 30 meter, V shape 60 degrees. Clearance 2, blunt edge 1-2 can. Submerged arc welding, the plate can be assembled after thinning, without beveling.

- Q:Can steel sheets be used for roofing purposes?

- Indeed, roofing purposes can be served by steel sheets. In commercial and industrial buildings, as well as residential homes, it is common to find steel roofing sheets being utilized. These sheets are renowned for their ability to withstand harsh weather conditions, including rain, snow, and wind, thereby ensuring their longevity and durability. Moreover, steel sheets come in various profiles and finishes, enabling customization to cater to different architectural styles and design preferences. Furthermore, steel roofing possesses the advantages of being lightweight, fire-resistant, and often crafted from recycled materials, thereby presenting an environmentally friendly roofing alternative. In conclusion, the strength, versatility, and aesthetic appeal of steel sheets make them a favored option for roofing.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot-dipped Galvanized Steel Sheet in Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords