Hot Dip Galvanized Steel Sheets in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

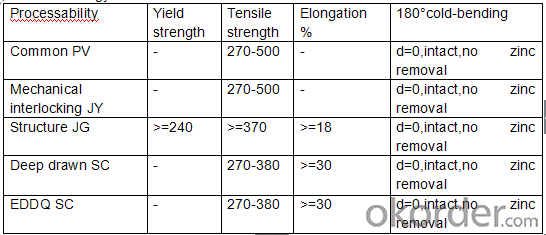

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q:How thick are steel sheets available?

- A wide variety of thicknesses can be found for steel sheets, catering to the specific needs of each application. Steel sheets commonly come in thicknesses ranging from 0.5mm (or 0.020 inches) up to several inches. Gauge is typically used to measure the thickness of steel sheets, with lower gauge numbers indicating thicker sheets. Nevertheless, it's worth mentioning that the availability of steel sheets in particular thicknesses might differ depending on the supplier and the type of steel employed.

- Q:Can steel sheets be used in furniture applications?

- Yes, steel sheets can be used in furniture applications. They are commonly used for creating sturdy and durable furniture pieces like tables, chairs, and shelves. Steel sheets provide strength, stability, and a modern aesthetic to furniture designs.

- Q:How do steel sheets handle bending or flexing?

- Steel sheets are known for their excellent strength and rigidity, making them highly resistant to bending or flexing. The inherent properties of steel, such as its high tensile strength and stiffness, allow it to withstand substantial external forces without deforming. Steel sheets can handle bending or flexing to a certain extent without compromising their structural integrity, making them suitable for a wide range of applications. When steel sheets are subjected to bending or flexing forces, they undergo a process known as elastic deformation. This means that the steel will temporarily change shape under the applied load, but it will return to its original form once the load is removed. This elasticity is due to the crystalline structure of steel, which allows it to absorb and distribute the stress evenly throughout its structure. However, it is important to note that steel sheets do have a limit to their bending or flexing capabilities. Beyond a certain point, the applied load can cause the steel to undergo plastic deformation, which results in permanent changes to its shape. This can lead to the formation of cracks or fractures in the material. The maximum amount of bending or flexing that steel sheets can tolerate before experiencing plastic deformation is determined by factors such as the thickness of the sheet, the grade and type of steel used, and the specific application requirements. To enhance the flexibility of steel sheets, certain processes such as cold rolling or annealing can be employed. Cold rolling involves passing the steel sheet through rollers at ambient temperature, which not only increases its strength but also improves its ability to withstand bending or flexing forces. Annealing, on the other hand, involves heating the steel to a specific temperature and then cooling it slowly to relieve internal stresses, making it more ductile and less prone to cracking. In conclusion, steel sheets are highly capable of handling bending or flexing due to their inherent strength, rigidity, and elasticity. However, it is essential to consider the specific application requirements and the limitations of the steel sheet to ensure its performance and longevity.

- Q:Can steel sheets be used for railway track components?

- Yes, steel sheets can be used for railway track components. Steel is a commonly used material in the construction of railway tracks due to its strength, durability, and resistance to wear and tear. Steel sheets can be used to manufacture various components of railway tracks, such as rails, sleepers, and fasteners, ensuring a reliable and long-lasting infrastructure for trains.

- Q:Are the steel sheets suitable for high-temperature applications?

- Yes, steel sheets are generally suitable for high-temperature applications. Steel is known for its excellent strength and durability, making it a popular choice for various industries requiring materials that can withstand high temperatures. Steel sheets can be manufactured to have high melting points and can retain their structural integrity even under extreme heat. Additionally, steel has good thermal conductivity, allowing it to efficiently transfer heat away from the surface. However, it is important to consider the specific grade and composition of the steel sheets as some alloys are specifically designed for high-temperature applications. It is recommended to consult with a materials engineer or specialist to ensure that the steel sheets selected are suitable for the specific high-temperature environment.

- Q:What are the bending and forming capabilities of steel sheets?

- Steel sheets have excellent bending and forming capabilities due to their high tensile strength and ductility. They can be easily bent into various shapes without losing their structural integrity, making them suitable for applications requiring complex designs and precise specifications. Additionally, steel sheets can be formed through processes such as rolling, stamping, and deep drawing, allowing for the production of a wide range of products with different shapes and sizes.

- Q:What is the thickness of the steel sheets?

- The thickness of the steel sheets can vary depending on the specific application and requirements. Common thicknesses for steel sheets range from 0.4 millimeters to several inches, with standard measurements including 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and so on. However, it is important to note that the thickness can be customized based on the intended use, such as for construction, manufacturing, or automotive purposes. Therefore, it is essential to consult the specifications or inquire with the manufacturer or supplier to determine the exact thickness of the steel sheets in question.

- Q:Can steel sheets be used for fire-rated doors?

- Fire-rated doors can indeed utilize steel sheets. In fact, steel is extensively employed in the creation of fire-rated doors due to its exceptional strength, longevity, and fire-resistance characteristics. Generally, steel sheets employed in fire-rated doors are crafted with multiple layers of fire-resistant substances, like gypsum or mineral core, which are placed between the steel sheets. This method of construction effectively impedes the propagation of fire and smoke, ensuring a dependable barrier in case of a fire. Furthermore, steel is renowned for its structural integrity, rendering it an appropriate option for fire-rated doors that must endure elevated temperatures and pressure.

- Q:How do steel sheets handle weathering?

- Steel sheets have been designed to effectively handle weathering. Typically, they are coated with a protective layer, such as zinc or a combination of zinc and aluminum, which creates a barrier against moisture and other environmental elements. This coating, known as galvanization, prevents the steel from corroding or rusting when exposed to rain, snow, and other forms of precipitation. Aside from the protective coating, various chemical processes are used to enhance the steel sheets' resistance to weathering. These processes may involve applying primers, paints, or sealants that further shield the steel from moisture, UV radiation, and extreme temperature fluctuations. Furthermore, the composition of steel itself contributes to its ability to withstand weathering. Steel is primarily comprised of iron, carbon, and other elements, forming an alloy that provides inherent strength and durability. This structural integrity enables steel sheets to resist deformation, cracking, or warping caused by weather-related stresses. However, it is important to acknowledge that even the most well-protected steel sheets may gradually experience some degree of weathering over time. Harsh environmental conditions can gradually degrade the protective coating, resulting in the formation of small areas of rust or corrosion. Regular maintenance, such as cleaning, inspecting, and reapplying protective coatings, can help extend the lifespan of steel sheets and preserve their resistance to weathering.

- Q:How do steel sheets perform in thermal conductivity?

- Steel sheets have a high thermal conductivity, which means they are efficient in transferring heat.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Dip Galvanized Steel Sheets in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords