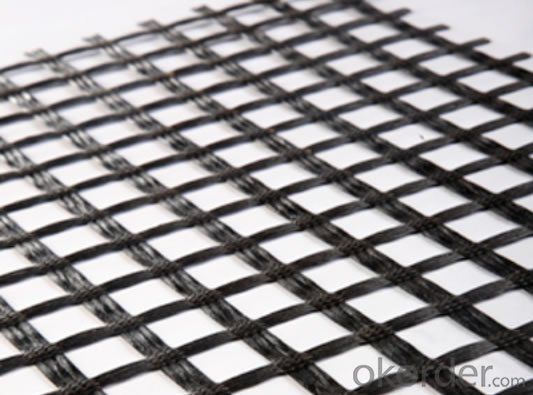

High Strength Fiberglass Geogrid in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Geogrid is widely used in civil construction over the whole world. It is manufactured on the basis of high-impact polyethylene and polypropylene. Geogrids are used as reinforcement materials on mellow soils for railway and car roads, parking places, landing grounds and for the reinforcement of bridge piers, slopes and earth banks, for erosion protection of slopes.

1)fiberglass geogrid with CE certificate

2)Materials:fiberglass

3) Tensile strength:MD/CD:30 ~ 200kn/m

4)WIdth:1 ~ 6m

Material Major Advantages

Geogrid application is a way of soil reinforcement, On soil surface a plate is created according to the thickness of a corresponding geogrid: 50 mm, 100 mm, 150 mm, 200 mm (this standard range of products is manufactured by “Technostroytex” LLC).

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:How are geogrids used in civil engineering?

- Geogrids are used in civil engineering to reinforce soil, stabilize slopes, and strengthen the base of roads and retaining walls. They are typically made of high-strength polymer materials and are installed in layers to provide additional structural support and prevent soil erosion. Geogrids help distribute loads, increase soil stability, and enhance the overall durability and performance of civil engineering structures.

- Q:What is the lifespan of geogrids in typical applications?

- The lifespan of geogrids in typical applications can vary depending on various factors such as the specific type and quality of the geogrid, the environmental conditions, and the level of stress or load applied to the geogrid. However, in general, geogrids are designed to have a long lifespan ranging from 20 to 50 years or even more in some cases. Regular maintenance and inspection can help extend the lifespan of geogrids and ensure their continued effectiveness in their intended applications.

- Q:Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are commonly used in soil stabilization and reinforcement applications, and their high tensile strength and durability make them effective in preventing soil erosion and improving the stability of mine tailings containment structures. Additionally, geogrids can enhance the overall performance and longevity of the containment system by providing reinforcement to the soil and reducing the risk of slope failure or structural deformation.

- Q:What is the effect of creep rupture on geogrid performance?

- The effect of creep rupture on geogrid performance is the gradual weakening and potential failure of the material over time due to sustained loads and prolonged exposure to environmental factors. Creep rupture reduces the geogrid's ability to provide long-term reinforcement and stability, compromising its overall performance and effectiveness in various engineering applications, such as soil stabilization and retaining walls.

- Q:meters. Material: tgsg. This section of subgrade for soft soil foundation (water) what is the purpose and principle of this treatment? Seeking answers experienced master change, or in the design the unit did. Thank you. Do a detailed description of indebted forever. My understanding is...Geogrid width of 3 meters, the berm soil subgrade body laying 1.4 meters, laying 1.6

- Do you understand the true role of geogrid?

- Q:What is the geogrid GSJ80/HP

- 2, no long-term creep as reinforcing material, have in long-term load under the condition of deformation resistance that the creep resistance is extremely important, glass fiber does not creep, which ensure product can maintain long-term performance.3, thermal stability - the melting temperature of glass fiber above 1000 degrees Celsius, which ensures that the fiberglass geogrid in paving operations to withstand the heat stability.

- Q:Glass fiber grille modified asphalt, polyester grille coated PVC.

- It has 18 kinds of grid equipment production line, the main production and operation of all kinds of glass fiber geogrid, warp knitted polyester geogrid, unidirectional tensile plastic geogrid, two-way stretch plastic coal mine supporting soil to help network, with two-way welding plastic top net plastic composite geogrid, coal mine under biaxial tensile plastic,

- Q:What is the difference between Geogrid and geogrid

- Glass fiber mesh used in exterior wall, interior wall paint, mainly to prevent cracking, different materials at the junction of mortar plastering material hollowing. Local node reinforcement will also be used. Geotextile has excellent filtration, drainage, isolation, reinforcement, seepage prevention, protection, light weight, high tensile strength, good permeability, high temperature resistance, anti freezing, anti-aging, corrosion resistance. Common non-wovenUsed in the water layer, polyethylene polypropylene fiber waterproof is also used.

- Q:Can geogrids be used in reinforcement of underground structures?

- Yes, geogrids can be used in the reinforcement of underground structures. Geogrids are commonly used to provide additional strength and stability to soil layers, and they can be effectively utilized in underground construction projects to reinforce the surrounding soil and prevent potential collapses or deformations.

- Q:How do geogrids improve the load-bearing capacity of soils?

- Geogrids improve the load-bearing capacity of soils by distributing and reinforcing the applied loads across a wider area. They create an interlocking network within the soil, increasing its overall strength and stability. This reduces soil deformation, preventing settlement and ultimately enhancing the soil's ability to support heavy loads.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Strength Fiberglass Geogrid in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords