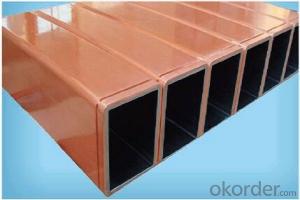

High Density Copper Profile for Electrical Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product: high density copper profile

Type Specifications: T2, TU1, TU2

Copper profile is processed copper with special shapes, and is mainly used in electric power equipment, railway sliding wire, and electronic leadframe, Feichi Copper & Aluminum owns several patents for high-density copper profile production, with the products of strong competitiveness and widely welcomed by the customers

High density copper profile Specifications

Type | Cu%(WT) | W%(WT) | RWMA | Density | E-conductivity(Min) | heat conduction | thermal expensivity | |

Class | (Min) | Hardness | ((W/mK)) | |||||

(Min) | ||||||||

CuW55 | 45±2 | Balance | 10 | 12.30g/cm3 | 49%IACS | 125HB | ~260 | ~11.7(10-6/K) |

CuW60 | 40±2 | Balance | 12.75g/cm3 | 47%IACS | 140HB | |||

CuW65 | 35±2 | Balance | 3.30g/cm3 | 44%IACS | 155HB | |||

CuW70 | 30±2 | Balance | 13.80g/cm3 | 42%IACS | 175HB | ~240 | ~9.7(10-6/K) | |

CuW75 | 25±2 | Balance | 11 | 14.50g/cm3 | 38%IACS | 195HB | 200~230 | 9.0~9.5 (10-6/K) |

CuW80 | 20±2 | Balance | 12 | 15.15g/cm3 | 34%IACS | 220HB | 190~210 | 8.0~8.5 (10-6/K) |

CuW85 | 15±2 | Balance | 15.90g/cm3 | 30%IACS | 240HB | 180~200 | 7.0~7.5(10-6/K) |

Copper profile is processed copper with special shapes, and is mainly used in electric power equipment, railway sliding wire, and electronic leadframe, we owns several patents for high-density copper profile production, with the products of strong competitiveness and widely welcomed by the customers

- Q:i want to magnatite a copper vessel.....i mean if i want to convert copper into magnet, what chemical shall i use, i heard that , ferrous oxide will do the work..but if so, what is the melting point and where do i find this chemical in india...pls give me full details

- You can't make a magnet out of copper. Only Iron and Nikkel (and their alloys, and less often derived chemicals from these) can be magnetised, and it is not a chemical process. Rather it is done by exposing them to a strong magnetic field. ferrous oxide (Magnetite) is an Iron compound that is naturally magnetic. It can be mixed with other chemicals to make a magnetic fluid, but I am not sure whether can be made to dry and stick to another surface. If it does, the object will no longer look like it's made of copper. The best you can do is to coat your vessel in a thin layer of Iron or Nikkel, and then magenetise it (by stroking it with another magnet). But then you might have the same problem, your vessel will not look like copper. If you go through all this trouble you can just as well use magnetic paint. I am not sure were to get that in India, but it is available here (in South Africa) in DIY shops. People buy it to paint walls in a kids playroom, so that they can write on it with cryons, and stick magnetic objects to it.

- Q:A copper penny has a mass of 3.015g and contains 95% Cu. If Cu costs 80 cents per pound what is the value of the copper in 100 pennies?

- It has been a long time since copper was 80c per pound. Canada in Feb of this year, stopped using pennies because of the expense. But that is not your question. I'll answer what a penny costs to manufacture today as well. 3.09 dollars per pound. Also as of 1992 pennies were made of more zinc than copper. Pennies contain nowhere near 92% copper. 3.015 grams /coin']* [ 1 pound / 454 grams] * [80 c / pound] * [95 coin /100 copper] = 0.507 cents/copper amount is what it is worth. Now as an exercise do 309 cents. You should come to 1.95 cents. That's why coins are not 95% copper.

- Q:A 150g piece of copper heated to 80°C is placed in the water. The water is stirred thorougly. After sufficient time elapses, to what temperature does the water change?Assume that no heat is transferred to or from the environment. The specific heat of water is 4.2 J/g.K , and copper's is 0.40 J/g.K

- ? Q1 = [m○(copper).cp(copper) + m(water).cp(water)]T1 Q2 = m(copper).cp(copper) T2 ? ??? Q1+Q2 = Q3 = [(m○(copper)+m(copper)).cp(copper) + m(water).cp(water)].T3 ; T3 > T1 → T3 = {[m○(copper).cp(copper) + m(water).cp(water)]T1 + m(copper).cp(copper).T2]/ [(m○(copper)+m(copper)).cp(copper) + m(water).cp(water)] → T3 =((0,1*400 + 0,2*4200)*20 + 0,15*400*80)/(0,25*400 + 0,2*4200) = 23,83 °C @+ ;)

- Q:I always thought it was Imperial Brass Mfg. in Chicago, Ill. back in the early 1930‘s. Someone recently told me they thought Reed Mfg. invented them in 1886. Anybody have any concrete proof and or links to find out the real scoop.

- I have no idea what a tube cutter is. my pipe cutter I have are for PVC pipes, I doubt it can cut metal. Well, if you own a good shotgun, take it to a gunsmith. if you own some cheap one like mine, where unless I break it the value couldn't possibly get any lower, DIY cut. If your shotgun is for fun shooting, you don't need to re-crown the muzzle. Not crowning will reduce accuracy, generally unless you're hunting/trap shooting with it, it doesn't really matter. cutting down a barrel with a hacksaw is exactly what it is. use a bench vise to hold the barrel (remove it from the shotgun), measure out 19 inches or just a bit more, check to make sure even with the cut made the shotgun will still meet length requirements. 18 barrel and 26 overall. use a hacksaw and cut as straight as possible thru the barrel. The steel is surprisingly soft. I use my cheap used $100 shotgun for plinking use. the barrel I cut down to 18.75. I used a hacksaw. The cut isn't square to the barrel, oh well. I used a dremel tool to clean up the edges. then a file to make the sanding marks smooth.

- Q:I have a copper IUD the NOVA-T by Bayer.My boyfriend has ejeaculated in me... is that safe ?what are the chances I am pregnant ?I am supposed to get my period in like 3/4 days.This morning I have been throwing up with diarrhea cause i ate some old chickenand i didnt knowPLEASE GIVE ME ALL THE INFO YOU KNOW !& PERSONAL EXPERIENCE

- I had a copper IUD for 3 years and I had unprotected sex with my husband the whole time. He ejaculated in me, and I never turned up pregnant. If you are with someone stable the IUD is so that you CAN have unprotected sex. Yes there is a small small small chance of pregnancy with it as there is with any other form of birth control but it is highly unlikely. You will get your period on time and there is a 99.9% chance of you NOT being pregnant. If your really that worried about it then you should talk to ur doctor and get all the info on IUD's.

- Q:how to repair leak on air copper pipe picture attached?

- put a pc of rubber on it clamp it with a hose clamp

- Q:Is a copper pipe a clue that water runs through it?

- Goto the dealership and they will have a huuuuge book, itll be in there, take a pic with your camera phone or something.

- Q:My horrible bathroom project is killing me. Everything drips. I bought a new shut off valve 1/2 to 3/8, and that does not fit into the water line from the wall. I looked at my old shut off valve and it had a piece that screwed into the 1/2 inch side and then it screwed on. I know its not 3/8‘s, so what the heck side could it be? The 1/2 was to big. I am stumped?My lines are corroded a little bit at the threaded part of the water line that come out of the wall. I am sure that this is also causing these drips I get. Is there anyway to fix this without replacing the pipes? Gaskets, seals? My house is about 60 Years old, and I don‘t see myself here for to long and I don‘t have allot of money to spend on this.Thanks

- It would appear that you have copper pipes, but have some unusual fittings. You might try a simple method, before resorting to replacing everyrhing. Teflon tape just could be your answer, but the surfaces MUST be clean. Remove the fittings, clean the threads with a strong detergent and steel wool, to get rid of all traces of corrosion. You must clean both the male and female ends of each fitting, . Rinse away ALL detergent and any bits of steel wool, then tightly wrap the teflon tape around the threads and re-use the original fittings. EDIT A magnet covered with food wrap or inside a plastic bag and held near the fittings will usually collect the last bits of steel wool. After use, remove the magnet from the food wrap/bag and the bits will fall away easily.

- Q:What is the charge of Copper?How do you determine it?

- Copper 2 Nitrate Formula

- Q:Well... I need some information on:If we use Iron nails, and we wrap copper wire around them, and use batteries to create magnetism.I know that the copper wire will probably create more of an electric charge, and add on to the magnetism. this is what I need answered, however. Why does this cause the magnetism to enhance? And is it used in some basis of creating energy?

- The fact that the copper wire is coiled is crucial. By running a electric current through the wire, you are creating an induced magnetic field through the iron nail. This is the principle of inductance. Remember, when you create an electric field, you are also creating a perpendicular magnetic field. The coils are creating a nearly circular (planar) path for electron flow, so the magnetic field is oriented along the axis of the nail (right-hand rule). If the iron nail already has a magnetic field present, then you have an addition/superposition of magnetic fields. Otherwise, the source of the magnetism is solely inductance. Applications of induction principles include motor and generator design.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Density Copper Profile for Electrical Equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords