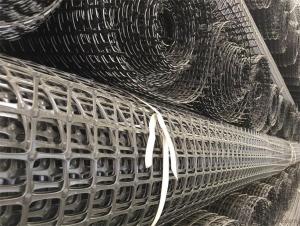

Grass Protection Geogrids Light Weight in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

The geogrid elements vary in polymer type and cross-sectional dimensions. They can sometimes change shape and dimensions within their length. Geogrids are either integrally manufactured (punched and drawn sheets; or extruded), ultrasonically or adhesive bonded strips, or joined in a knitting or weaving process and then coated. Polymer types include polyethylene, polypropylene or high tenacity polyester that has been coated.

Although geogrids are used primarily for reinforcement, some products are designed for asphalt overlay and waterproofing or for separation and stabilization. Geogrids also are used as gabions and sheet anchors, inserted between geotextiles and geomembranes, or used to construct mattresses for fills or embankments over soft soils.

WEIGHT

300G/SQM

500G/SQM

ELONGATION AT BREAK

3%

TENSILE STRENGTH IN KNOT

5KN/M

10KN/M

WIDTH:

1--6M

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q:Are geogrids suitable for use in landfill liners?

- Yes, geogrids are suitable for use in landfill liners. Geogrids are commonly used in landfill liner systems to enhance stability and prevent lateral soil movement. They provide reinforcement, improve drainage, and increase the overall performance and longevity of the landfill liner.

- Q:Can geogrids be used in reinforcement of soil-bentonite mixtures?

- Yes, geogrids can be used in the reinforcement of soil-bentonite mixtures. Geogrids are commonly used in geotechnical engineering for soil stabilization and reinforcement. They can improve the tensile strength and overall stability of soil-bentonite mixtures, making them a suitable choice for reinforcement purposes.

- Q:Do geogrids enhance the load-bearing capacity of soil?

- Yes, geogrids enhance the load-bearing capacity of soil.

- Q:EG65R type geogrid meaningWhat is the meaning of EG, said 65 per meter of tensile strength is 65kN? 65KN/m R will be broken? What is the meaning?

- 65 means should be the latitude to pull is 65KN for fiberglass and polyester grid, there is no argument per meter of tensile strength,

- Q:Do geogrids require any maintenance?

- Yes, geogrids generally do not require any maintenance once they are properly installed. They are designed to be durable and resistant to environmental factors, reducing the need for regular maintenance.

- Q:Who knows the laying method of geogrid?

- Geogrid price Description: now all over the country, many manufacturers of geogrid, product prices vary, the price of raw materials and the impact of regional differences,

- Q:Can geogrids be used in retaining wall facing systems?

- Yes, geogrids can be used in retaining wall facing systems. Geogrids are commonly used as reinforcement in retaining walls to provide additional stability and strength. They are placed horizontally within the soil layers behind the retaining wall facing to distribute the loads and prevent soil movement. This helps to enhance the overall structural integrity of the retaining wall and improve its longevity.

- Q:What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it can significantly impact the mechanical properties and performance of the geogrid. At higher strain rates, the geogrid may exhibit increased stiffness and strength due to the rate-dependent nature of its materials. This means that the geogrid can better resist deformations and provide enhanced stability under dynamic loading conditions. However, at extremely high strain rates, the geogrid may experience reduced performance and even failure due to excessive stress concentrations and insufficient time for dissipation of energy. Thus, understanding and considering the strain rate is crucial in designing and applying geogrids for different applications.

- Q:What are the types of geogrid, respectively, what role?

- Glass fiber geogrid features:The product has the characteristics of high strength, low elongation, high temperature resistance, high modulus, light weight, good toughness, corrosion resistance, long service life, can be widely used in the old cement pavement and airport runway maintenance, dams, river, slope protection, bridge pavement engineering field enhancement processing, can give the pavement reinforcement and reinforcement to prevent rutting, fatigue crack of pavement, hot and cold crack and the expansion of reflection crack, and can disperse the bearing capacity of pavement and prolong the service life of the pavement, high tensile strength and low elongation, no long-term creep, high physical and chemical stability, thermal stability, fatigue cracking, rutting resistance, cracking resistance at low temperature delay, reduce the reflection crack.

- Q:I am a site using two-way 80 plastic geogrid, the need to use U type nails specifications and prices? Consultation with the construction process, thank you.Correction: two-way 80 steel plastic geogrid.

- Key points of quality technology1. The quality of geogrid conforms to the requirements of drawings or specifications.2, the laying of geogrid should be straightened straight down to the underlying layer. There should be no distortion, wrinkle, overlap, the use of artificial tension, the use of U type nails fixed on the surface of the base.3, the connection between the geogrid should be solid, its stack length is not less than 30cm.4, the surface of the soil layer should be smooth, less than 8cm geogrid Embankment Filler, the maximum particle size should not be greater than 6cm.5, the geogrid is laid in a timely manner in its fill, in order to avoid its exposure to the sun for a long time, not because of the soil geogrid.6, the filling layer paving, layered rolling. On the basis of the method, the upper subgrade filling.7, different levels of geogrid connection position should be staggered. Construction should avoid transport vehicles and other construction machinery in the shop has spread to direct rolling and tension of Geogrid on location.8, the key of laying geogrid is to ensure continuity, to avoid distortion, fold, overlap, pay special attention to avoid excessive tension, to prevent exceeding the tensile strength and deformation limit failure and tear.Steel grating 80KN bandwidth should be between 1.6-1.8cm, fixed with U nails as long as the diameter larger than this size OK, as for the price, hardware stores should have to sell, not very expensive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grass Protection Geogrids Light Weight in Civil Engineering Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords