Grade AISI1045 Din1.1191 JIS s45c GB45 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Grade AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Details of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Name | SAE1045 Carbon Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Grades Comparison

GB | ASTM | JIS | DIN | BS | NF |

45# | 1045 | S45C | C45 | IC45 08047 | C45 |

Chemical Composition

C | Si | Mn | Cr | P/S | Cr |

0.42-0.50 | 0.17-0.37 | 0.5-0.8 | ≤0.25 | ≤0.35 | 0.3-0.5 |

Sizes information

Sizes detalis | diameter | 16-320mm |

length | 3-12m(canbe customerized) | |

Sizes tolerance (max) | length | +/-100mm |

diameter | +/-2mm | |

Straightness | 3mm/m |

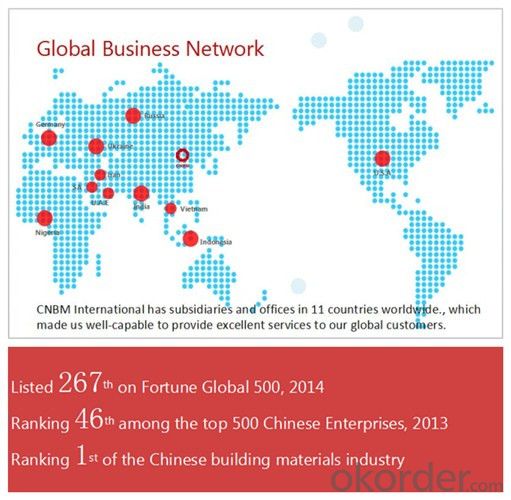

CNBM Introduction of AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery AISI1045_Din1.1191_JIS s45c_GB45 Hot Rolled Carbon Steel Round Bar

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the different surface hardening techniques for special steel?

- There are several surface hardening techniques that can be used for special steel to enhance its mechanical properties and improve its wear resistance. These techniques include: 1. Case hardening: This method involves introducing carbon or nitrogen into the surface of the steel through diffusion. The steel is heated in the presence of a carbon-rich or nitrogen-rich environment, causing the carbon or nitrogen atoms to diffuse into the surface layer. This process forms a hardened case while maintaining a tough core. 2. Nitriding: Nitriding is a surface hardening process that involves the diffusion of nitrogen into the steel. The steel is placed in a nitrogen-rich environment at elevated temperatures, forming a hardened surface layer with improved wear resistance and corrosion resistance. 3. Carburizing: Carburizing is a process that involves introducing carbon into the surface of the steel. The steel is heated in a carbon-rich environment, allowing the carbon atoms to diffuse into the surface layer. This forms a hardened case with increased hardness and wear resistance. 4. Induction hardening: Induction hardening is a localized surface hardening technique. The steel is heated using an induction coil, and then rapidly quenched. This process results in a hardened surface layer with high hardness and improved wear resistance. 5. Flame hardening: Flame hardening is another localized surface hardening method. The steel surface is heated using a high-temperature flame and then quickly quenched. This technique produces a hardened surface layer with increased hardness and wear resistance. 6. Laser hardening: Laser hardening is a precise and localized surface hardening technique. A laser beam is used to heat the desired area of the steel, followed by rapid quenching. This process forms a hardened surface layer with enhanced mechanical properties. These surface hardening techniques for special steel can significantly improve its durability, strength, and resistance to wear and corrosion, making it suitable for various industrial applications. The selection of the most appropriate technique depends on factors such as the desired hardness level, the complexity of the steel component, and the specific requirements of the application.

- Q:How does special steel compare to stainless steel?

- Special steel and stainless steel are both types of steel, but they differ in their composition and properties. Special steel refers to a broader category of steel that encompasses various types with specific properties tailored for specific applications, whereas stainless steel is a specific type of special steel known for its resistance to corrosion. While special steel can be customized to meet specific mechanical, thermal, or electrical requirements, stainless steel excels in providing excellent corrosion resistance, making it suitable for applications in environments with high moisture or chemical exposure. So, in summary, special steel is a broader category, while stainless steel is a specific type within that category, known for its corrosion resistance.

- Q:How does special steel perform in additive manufacturing applications?

- Special steel performs well in additive manufacturing applications due to its high strength, durability, and resistance to wear and corrosion. The unique properties of special steel, such as its ability to withstand high temperatures and extreme environments, make it an ideal material for 3D printing processes. Additionally, the flexibility and customization offered by additive manufacturing allows for the creation of complex geometries and intricate designs, further enhancing the performance of special steel in various applications.

- Q:Does special steel require special machining techniques?

- Yes, special steel often requires special machining techniques due to its unique properties and characteristics. Special steels can have higher hardness, greater strength, improved corrosion resistance, or other desirable attributes that make them more challenging to machine compared to regular steels. Specialized cutting tools, machining parameters, and techniques may be necessary to achieve the desired precision, surface finish, and dimensional accuracy during the machining process.

- Q:Can special steel be used in the wood manufacturing industry?

- Yes, special steel can be used in the wood manufacturing industry. Special steel, such as tool steel, can be used to make cutting tools, blades, and other equipment used in wood processing and manufacturing. These steel tools offer high strength, durability, and resistance to wear, enhancing the performance and longevity of wood manufacturing machinery.

- Q:How does special steel contribute to the automotive sector?

- Special steel contributes to the automotive sector by offering enhanced strength, durability, and resistance to wear and tear. It is used in various critical components such as engine parts, suspension systems, and safety features, improving performance, safety, and overall reliability of vehicles. Additionally, special steel enables the development of lightweight designs, aiding in fuel efficiency and reducing emissions.

- Q:What is the impact of high temperature on the mechanical properties of special steel?

- The mechanical properties of special steel are significantly affected by high temperature. When subjected to high temperatures, special steel may experience thermal softening, which leads to a decrease in its mechanical strength. This is primarily caused by the reduction in yield strength and hardness of the material at elevated temperatures. One of the main consequences of high temperature on special steel is the decrease in its ability to resist deformation. At elevated temperatures, the steel becomes more ductile, making it more prone to elongation and plastic deformation. This increase in ductility can result in a loss of shape and integrity under load, leading to distortion, warping, or even component failure. Additionally, high temperatures can induce changes in the microstructure of special steel. Prolonged exposure to elevated temperatures can result in the formation and growth of grain boundaries, weakening the material's mechanical properties. Moreover, high temperature can facilitate the diffusion of impurities or alloying elements within the steel, altering its chemical composition and potentially affecting its mechanical behavior. Another consequence of high temperature on special steel is the decrease in its resistance to corrosion and oxidation. At elevated temperatures, the steel becomes more vulnerable to oxidation, leading to the formation of scales or even complete degradation of the material. This compromises the steel's mechanical properties, including its strength and toughness. In conclusion, high temperature has a detrimental impact on the mechanical properties of special steel. It reduces strength, increases ductility, alters microstructure, and decreases resistance to corrosion and oxidation. Therefore, it is crucial to consider the effects of high temperature when designing and selecting special steel for applications involving exposure to elevated temperatures.

- Q:What are the limitations of special steel?

- Some limitations of special steel include its high cost and limited availability, as well as the difficulty in shaping and processing it. Additionally, special steel may have lower tensile strength compared to other materials and can be prone to corrosion if not properly maintained.

- Q:How does special steel perform in high-temperature corrosion?

- Special steel performs well in high-temperature corrosion due to its unique composition and properties. It is designed to resist oxidation, scaling, and other corrosive reactions at elevated temperatures. The alloying elements present in special steel, such as chromium, nickel, and molybdenum, form a protective oxide layer on the surface, preventing further corrosion. Additionally, the high strength and heat resistance of special steel make it an ideal choice for applications in high-temperature environments, ensuring long-term performance and durability.

- Q:What is the role of special steel in the manufacturing of precision instruments?

- Special steel plays a crucial role in the manufacturing of precision instruments. Precision instruments, such as watches, surgical instruments, measuring tools, and aerospace components, require materials that possess exceptional qualities like durability, strength, corrosion resistance, and dimensional stability. Special steel, with its unique composition and properties, is specifically engineered to meet these demanding requirements. One of the key advantages of special steel is its high level of purity and uniformity. It undergoes extensive refining and purification processes to remove impurities, ensuring consistent and reliable performance. This purity is essential in precision instruments as it minimizes the risk of contamination, which could lead to inaccuracies or failures in their functioning. Another vital characteristic of special steel is its exceptional strength and hardness. Precision instruments often need to withstand high levels of stress, pressure, or mechanical forces without deforming or failing. Special steel, with its superior strength, provides the necessary structural integrity and stability to these instruments, allowing them to maintain their accuracy and reliability over time. Moreover, special steel exhibits excellent corrosion resistance, which is crucial for precision instruments that may come into contact with moisture, chemicals, or other corrosive substances. Corrosion can deteriorate the surface finish and compromise the functionality of the instruments. Special steel's resistance to corrosion ensures that the instruments can withstand harsh environments and continue to perform accurately. In addition to its physical properties, special steel is highly machinable and can be shaped into complex and intricate components with tight tolerances. Precision instruments often require intricate designs and intricate parts that demand high precision in their manufacturing process. Special steel's machinability allows for the production of these complex components with utmost precision, ensuring the overall accuracy and functionality of the instruments. In summary, the role of special steel in the manufacturing of precision instruments is vital. Its purity, strength, corrosion resistance, and machinability make it an ideal material for producing high-quality instruments that can deliver precise measurements, withstand demanding conditions, and maintain their accuracy over time. Without special steel, the production of precision instruments with such exceptional qualities would be significantly compromised.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Grade AISI1045 Din1.1191 JIS s45c GB45 Hot Rolled Carbon Steel Round Bar

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords