Gear planetary gear CNH OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

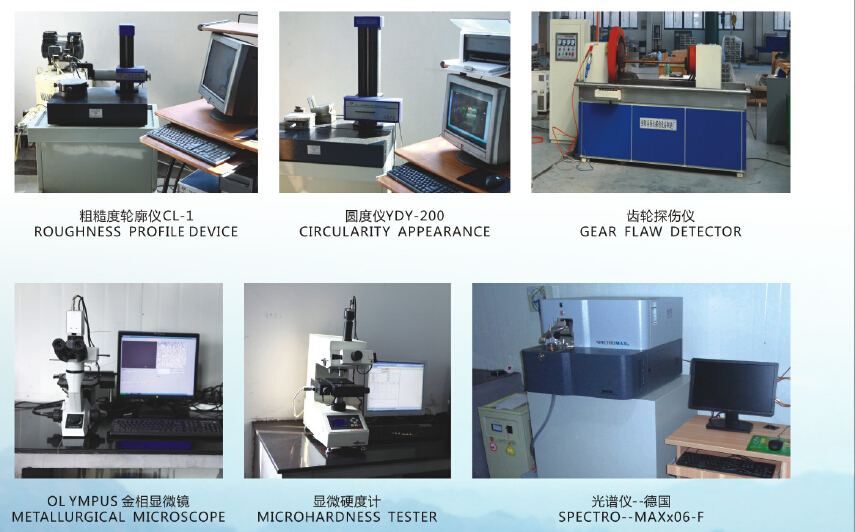

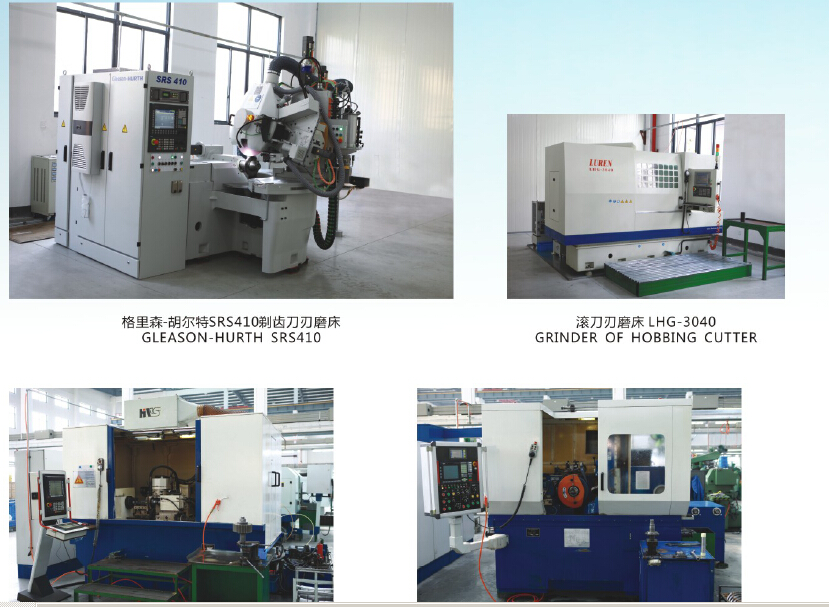

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q:How to find the damage of automobile flywheel ring

- Two is the direct meshing, can not start. You can start several times, possibly.Three is not really, you can turn the engine crankshaft, let the flywheel to a certain angle, and then start to avoid the damaged position, you can start normally.

- Q:Planetary gear reduction problem. The outer gear ring is fixed with 80 teeth, the planet tooth is 30 teeth, the center tooth is 20 teeth.1, can the meshing drive.2, the planet carrier input power, the sun tooth output power. What is the speed ratio?

- Drive ratio = active speed / driven speed = number of driven teeth / active teeth number)

- Q:305 modern excavator slewing ring to install

- First remove the slewing ring (slewing table), then find a 20 ton crane to lift the whole upper frame

- Q:Is there any dust in the punching ring that affects the abs?

- When the gear ring is contaminated, the sensor will misread the signal and assume that the relative two wheel speeds are inconsistent, resulting in sideslip, and the ECU will give the side braking signal to keep the speed consistent. Reflects the driving is vehicle deviation.

- Q:How is the flywheel connected to the ring?

- Storage of part of the energy in the engine's work stroke to overcome the resistance of other strokes and rotate the crankshaft evenly.

- Q:The number of teeth in my inner ring gear is 80, the modulus is 6, the addendum factor is 0.8, and the root coefficient is 0.25

- Explain that the 90 degree place is for you to fill in the angle between the members of the array. If you want to fill it, it's obviously 360/44, but the system will be decimal, so there will be a gap. The back 360 degrees means that your 44 units are evenly distributed in these 360 degrees, and there must be no clearance. That is, in drawing, 360 and 90 are optional only one as a qualifier.

- Q:What's the relationship between the number of teeth on the flywheel ring of the engine and the election? I know that it is engaged with the starter. Is it possible to choose a small starter to start fast? How can I choose this?

- This can not be arbitrarily selected, choose a few teeth seriously affect the motor use, may be burned, as stipulated in the diesel engine has a specified number of the diesel engine gear, such as Yulin 6105QC is -110 gear

- Q:There is no gear with teeth inside or outside, or it is called a ring. The inner teeth are used for internal meshing, and the outer teeth are used for external meshing. Thanks for your help

- 2, in the transmission of special circumstances, may also have a special gear, both internal and external gear for example, planetary gear drive, a ring gear (also called the internal gear), in the transmission process, if the needs of the entire planetary system to do a whole week to swing, then, can be in a tooth a special ring gear has internal and external gear.

- Q:What is the radial runout error of the ring gear?

- Radial runout error of gear ring:The ring gear is in gear to a radial runout range, double contact probe in the slot on the tooth and the tooth to live in high school and tooth, the biggest change in measuring head relative to the gear axis. It mainly reflects the radial error components' geometric eccentricity caused by circular gear error motion. The common normal length changes can be assessed in combination with 6-8 level precision gear, if only for individual control below 9 grade low precision gear

- Q:Free car gear how to locate the school to start with the electric vehicle

- There is an error between the toothed ring and the starter of the car,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gear planetary gear CNH OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords