Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Material: | Steel,as requirements | Processing: | Forging | Pressure Angle: | 20 |

| Place of Origin: | Zhejiang China (Mainland) | technology of material: | forging | technology of machining: | hobbing,shaving,grinding |

| heatreatment: | nitriding,carburization | OEM: | is acceptable |

Packaging & Delivery

| Packaging Detail: | packed in carton |

| Delivery Detail: | 70days |

Specifications

1.produce as drawings

2.material will be as requirements

3.strictly quality control

4.OEM is acceptable

Products information:

1. suitable for many sorts of transmission system, such as agriculture tractor, wind power, truck and other industry zone.

2. material and precision can be as requirements.

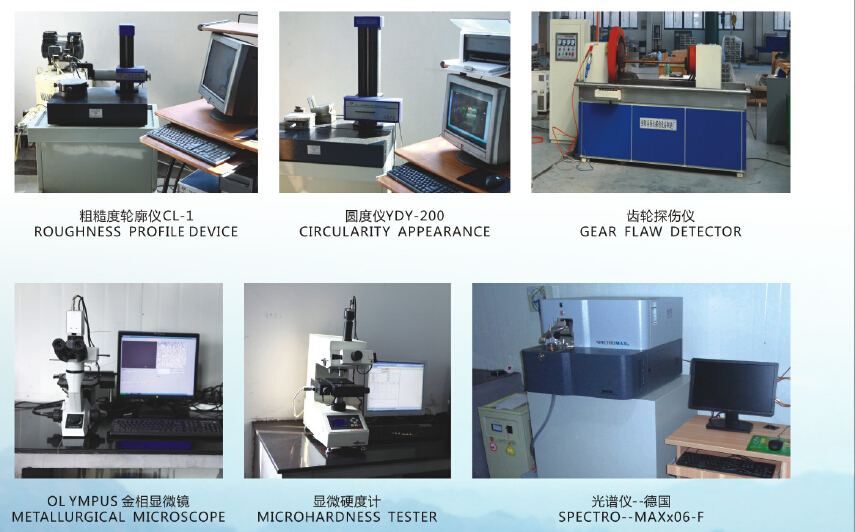

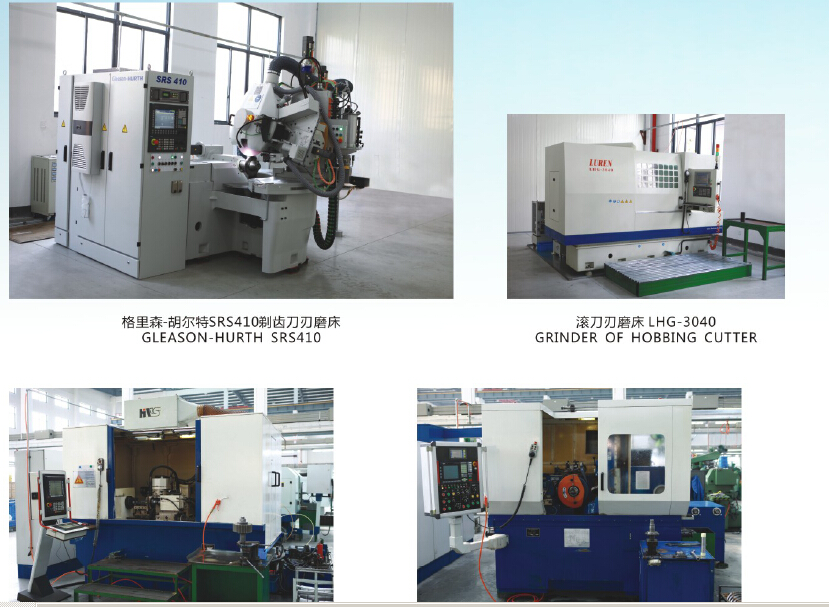

3. we have complete gear machining equipments: gear hobbing machine, shaving machine, gear shaper, gear grinding machine, and our own heat treatment center. all of the production procedure are strictly controlled by ourselves, no cooperation procession, so we can sure the final products to meet your requirements.

4.each processing, strictly quality control

5.certificate: ISO9001, ISO/TS16949

- Q:What is the difference between the mechanism of fine blanking and the mechanism of conventional blanking?

- The difference between the precision die and the ordinary die is that the V ring shaped clamp is adopted. The so-called ring gear plate is defined on the platen or die

- Q:How does the gear ring match the starter? Is there a method of calculating the work type? Tell me about it. Thank you

- The two parameters, the modulus m of the starter gear and the pressure angle alpha, can only be deduced

- Q:What's wrong with the gear ring slip?

- 2, there are three starter slip, first, there is not enough voltage. Two is the gear slip. The three tooth gear, and the gear ring gear wear, a great noise, those voices are not pulling metal. The first two kinds of circuit maintenance, it is best to find a mechanic teacher gear ring, in the maintenance of starter, or start the opportunity soon damaged.

- Q:Parameters of flywheel ring gear for single cylinder diesel engine

- So you have to be sure what your diesel engine is

- Q:The car mounted on the flywheel ring gear. How will annealing

- But this method is also worthy of attention, try not to use the method of heating the gas welding gun, welding gun for heating will cause uneven heating and deformation of the ring gear, once again that the temperature is not easy to grasp the annealing. The best way is to use cotton, with a certain amount of diesel oil evenly around the ring gear, such as heating can be said to be in the fire flame, fire is a part of the lowest temperature, so as not to make the gear ring annealing and reached the purpose of assembly.

- Q:What's the relationship between the number of teeth on the flywheel ring of the engine and the election? I know that it is engaged with the starter. Is it possible to choose a small starter to start fast? How can I choose this?

- The 6114A-143 6114B-125 6110-141 Wuxi gear tooth, Victoria WD615 has 136 teeth with 159 teeth, two teeth with different gear motor, a motor is equipped with 10 teeth, is a kind of motor with 11 teeth, 6112-108 teeth, 6CT-195 teeth tooth Cummins 6BT-173

- Q:How to install the gear ring of the rear oil seal of Lang Yi crankshaft?

- That way you can start?. The fire is a bit late. What else can you do?

- Q:The clearance between the slewing ring gear and the drive pinion

- And gear accuracy, installation center spacing is related to ~! See the manual ~!

- Q:How many teeth should the flywheel ring gear of the single speed diesel engine 158D12 teeth of the deceleration starter?

- functionAt the power output end of the crankshaft, that is, the transmission and the other side of the work equipment. The main function of the flywheel is to store the energy and inertia of the engine while doing the stroke. The four stroke engine has only one stroke to work, and the energy to absorb, compress, and exhaust the energy stored by the flywheel. The balance is correct. The balance of the engine depends mainly on the balance block on the shaft. The single cylinder machine has a balance shaft.

- Q:What is the main reason for the radial runout tolerance of gear ring?

- There are many reasons for the radial runout error of gear ring. The main cause of the radial runout error of gear ring is the geometric eccentricity, that is the gap between the hole of the gear blank and the mandrel of the fixture. If the production of small batch, with as little as possible gap fit (gear hole and mandrel); if large quantities, as far as possible to use expansion type centering method, to eliminate the gap, to reduce the gear jump has a certain role.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gear planetary sun gear OEM hobbing,shaving,grinding for machine OEM

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords