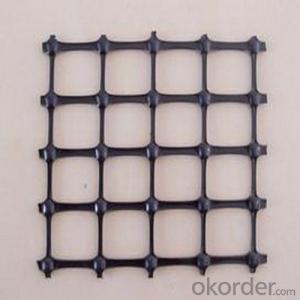

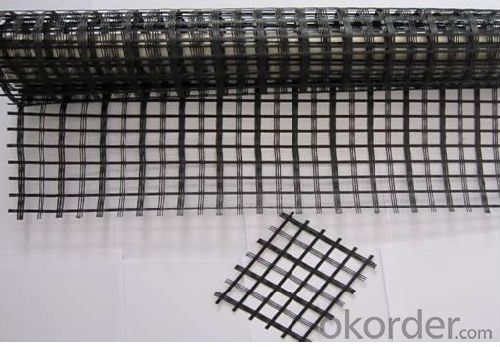

Fiberglass Geogrid with Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

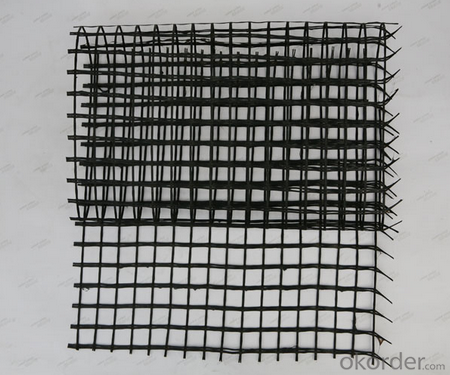

composite geogrid is made by blending high tensile steel wire which is specially processed and polyethylene (P.E.), and adds other accessory ingredients and though squeezing out to make it become complex belt that gas good tension resistance, and the surface ha rough embossing, which makes the reinforced geosynthetics belt. Based on the single belt and arranged by knitting or clamping vertically and horizontally according to certain space and fused on their connection points by using specially reinforced fusion-jointing technique, which makes the reinforced geogrid.

Performance

High intensity and small distortion

Slow creep

Anti-corrosive, long-term service life, steel plastic geogrid material with steel plastic material as its protector, and with various accessory ingredients to make the product have the abilities if anti-aging and anti-oxidation resisting permant project more than 100 years, and the performance is superior, the size stability is good.

The construction is convenient, the cycle is short, the cost is low; it is easy to lay down, join, locate, avoids overlapping cross over, but reduces the project cycle effectively, saves the building cost of projects by 10%--50%.

Application

The products are applied widely in railway, bridge, dock, retaining wall, dam ti reinforce the soft soil’s foundation and to resist the road surface’s crack.

Specifications

The high-strength One-way (vertical) Geogrid

Item | GSZ30 | GSZ50 | GSZ80 | GSZ100 | GSZ120 | GSZ150 |

Vertical limit-tensile strength KN/m ≥ | 30 | 50 | 80 | 100 | 120 | 150 |

Vertical limit elongation(%)≤ | 3 | |||||

The tensile strength of elongation at 1%KN/m ≥ | 23 | 38 | 63 | 81 | 98 | 125 |

The high-strength steel-plastic Two-way (vertical and horizontally) Geogrid

Item | GSZ30-30 | GSZ45-45 | GSZ60-60 | GSZ80-80 | GSZ100-100 | GSZ120-120 |

Biaxial ultimate tension KN/m ≥ | 30 | 45 | 60 | 80 | 100 | 120 |

Biaxial ultimate elongation (%)≤ | 3 | |||||

The tensile strength of elongationat 1% KN/m ≥ | 23 | 36 | 48 | 63 | 81 | 98 |

Packaging and storage

The Steel plastic composite geogrid, the length of the product roll is decided by the construction requests. The rolls are to be horizontally placed and not more than 6 layers high.

Unless otherwise specified, the production should be stored in a non-corrosive gas, non-dust, well-ventilated, dry and rainproof area.

It is recommended that the room temperature should be maintained below 35°C,and humidity should be always maintained below 65%

- Q:What are the potential drawbacks of using geogrids?

- One potential drawback of using geogrids is the high cost associated with their installation and maintenance. Geogrids are typically made from synthetic materials, which can be expensive to produce and purchase. Additionally, the installation process often requires specialized equipment and skilled labor, further increasing the overall cost. Another drawback is the limited effectiveness of geogrids in certain soil conditions. Geogrids are typically designed to enhance soil stability and reinforce weak or unstable soils. However, in cohesive soils or highly organic soils, geogrids may not provide the desired level of reinforcement. In such cases, alternative solutions or additional measures might be necessary. Moreover, geogrids require proper design and careful installation to ensure their effectiveness. If not installed correctly, geogrids may not perform as intended and could potentially fail. This could result in the need for costly repairs or replacements. Lastly, geogrids may have environmental concerns associated with their production and disposal. Synthetic materials used in geogrids are not biodegradable and may contribute to pollution if not properly managed. Additionally, the manufacturing process of these materials often involves the use of fossil fuels and can generate greenhouse gas emissions. Overall, while geogrids offer numerous benefits in terms of soil reinforcement and stabilization, it is important to consider their drawbacks, including high cost, limited effectiveness in certain soil conditions, installation requirements, and potential environmental impacts.

- Q:Can geogrids be used in reinforcement of embankments on expansive clays?

- Yes, geogrids can be used in the reinforcement of embankments on expansive clays. Geogrids are commonly used in such scenarios to improve the stability and performance of embankments by providing tensile strength and preventing soil movement. By distributing the load and reducing the potential for settlement, geogrids effectively reinforce embankments on expansive clays.

- Q:Are geogrids suitable for use in soft soil conditions?

- Yes, geogrids are suitable for use in soft soil conditions. Geogrids are engineered materials that provide reinforcement and stabilization to soils. They are specifically designed to improve the strength and stability of weak or soft soils. By distributing the loads and reducing soil movement, geogrids can effectively enhance the performance of the soil, making them a suitable solution for soft soil conditions.

- Q:What is the effect of aging on geogrid properties?

- The effect of aging on geogrid properties is generally a decrease in mechanical strength and stiffness. Over time, exposure to environmental factors such as sunlight, temperature variations, and moisture can cause degradation of the geogrid material, leading to reduced tensile strength, increased elongation, and diminished load-bearing capacity. The aging process can also result in changes to the geogrid's chemical composition and surface morphology, impacting its ability to interlock with surrounding soil particles and retain its original design characteristics. Therefore, it is crucial to consider the potential effects of aging when designing geogrid-based structures and to periodically assess their condition to ensure their long-term performance.

- Q:Geogrid nailed pictures and size

- U type nails, like the letter U, geogrid generally 0.6 multiplied by 80. You can also process

- Q:Refers to the size of the geogrid mesh holeSpecific attention is not clear, the banner of Chang Chang official CafeThere's something you're looking forGrille generally by the vertical and horizontal staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Geogrid generally by horizontal and vertical staggered from the simple meaning of space can also be understood that the size of the lattice gap.

- Q:What is the typical installation time for geogrids?

- The typical installation time for geogrids can vary depending on the size and complexity of the project, but it generally ranges from a few hours to a few days.

- Q:How do geogrids help in reducing the risk of settlement of structures?

- Geogrids help in reducing the risk of settlement of structures by providing reinforcement and stability to the soil. They are placed within the soil layer to distribute and transfer the load more evenly, thereby reducing the potential for settlement. By increasing the soil's strength and load-bearing capacity, geogrids help prevent excessive settlement and improve the overall stability and longevity of the structures.

- Q:How do geogrids improve pavement performance?

- Geogrids improve pavement performance by reinforcing the asphalt or concrete layers, increasing their strength and preventing cracks and deformations. They distribute the load more evenly, reduce fatigue and rutting, and enhance the overall durability and lifespan of the pavement.

- Q:Glass fiber grating with large pulling force for Expressway

- Fiberglass geogrid is mainly used for old road reconstruction, the main purpose is to reduce reflection cracks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Geogrid with Good Quality and Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords