DC Process Aluminum Coil for Casting to Thinner Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

DC Process Aluminum Coil for Casting to Thinner Coils

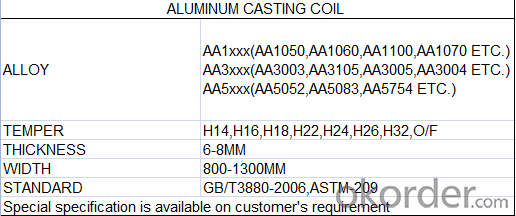

1.Structure of DC Process Aluminum Coil for Casting to Thinner Coils

DC Process Aluminum Coil for Casting to Thinner Coils is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. The thickness of DC Process Aluminum Coil for Casting to Thinner Coils is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the DC Process Aluminum Coil for Casting to Thinner Coils

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. DC Process Aluminum Coil for Casting to Thinner Coils

4. Production Process of DC Process Aluminum Coil for Casting to Thinner Coils

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of DC Process Aluminum Coil for Casting to Thinner Coils

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:How are aluminum coils used in heating, ventilation, and air conditioning (HVAC) systems?

- Aluminum coils hold a vital role in HVAC systems, specifically in heating, ventilation, and air conditioning. These coils are implemented in both the condenser and evaporator parts of the system. In the condenser, the aluminum coils aid in the transfer of heat from the refrigerant to the surrounding air. The refrigerant, which is in a state of high pressure and temperature after compression, flows through the condenser coils. As the air from the surroundings passes over these coils, the heat from the refrigerant moves to the air. This procedure contributes to the cooling of the refrigerant, transforming it from a gas into a liquid state. The cooled liquid refrigerant then moves to the evaporator coil. In the evaporator, the aluminum coils help in the absorption of heat from the indoor air. The liquid refrigerant enters the evaporator coils, where it experiences a change in phase from liquid to gas. As the warm indoor air passes over the coils, the refrigerant absorbs the heat, resulting in the cooling of the air. This cooled air is subsequently circulated back into the room, creating a comfortable indoor environment. The preference for aluminum coils in HVAC systems stems from their outstanding thermal conductivity, resistance to corrosion, and lightweight properties. These characteristics ensure effective heat transfer and enhance the overall performance of the system. Moreover, aluminum coils are more cost-efficient and environmentally friendly compared to materials like copper. Regular maintenance and cleaning of the aluminum coils are imperative to maintain their optimal functioning. Over time, dirt, dust, and debris can accumulate on the surface of the coils, hindering heat transfer and reducing efficiency. Thus, periodic cleaning is essential to preserve the performance of the HVAC system and prolong the lifespan of the aluminum coils.

- Q:Can aluminum coils be used in the production of cryogenic storage tanks?

- Cryogenic storage tanks can incorporate aluminum coils, as aluminum is a suitable material for such purposes. This is due to its low density, high thermal conductivity, and excellent resistance to corrosion. These attributes make it an excellent choice for the storage and transportation of cryogenic liquids like liquid nitrogen, oxygen, and argon. Aluminum coils can be utilized to construct the internal shell of the tank, which offers a lightweight and durable solution. Moreover, aluminum is highly malleable, enabling the creation of intricate tank shapes and designs. However, it is crucial to consider that aluminum has a higher coefficient of thermal expansion compared to materials such as stainless steel. Therefore, adequate design measures must be implemented to accommodate thermal contraction and expansion during cryogenic operations.

- Q:Can aluminum coils be used in the production of aluminum curtain walls?

- Yes, aluminum coils can be used in the production of aluminum curtain walls. Aluminum coils are typically used as the raw material in the manufacturing process of aluminum curtain walls. These coils undergo various processes, such as rolling, cutting, and shaping, to create the desired components of the curtain wall system. The lightweight and corrosion-resistant properties of aluminum make it an ideal material for curtain walls, as it provides structural stability, durability, and aesthetic appeal to the building façade. Overall, aluminum coils play a crucial role in the production of aluminum curtain walls, ensuring the quality and performance of the final product.

- Q:Can aluminum coils be formed into different shapes?

- Aluminum coils possess the capability to assume diverse configurations. Such metal, known for its high malleability, exhibits an ability to undergo bending, shaping, and forming without fracturing. This particular attribute deems it an optimal material for myriad applications necessitating flexibility and adaptability. Aluminum coils, employing a myriad of techniques like bending, rolling, stamping, extrusion, or even specialized machinery like a coil forming machine, can be fashioned into an array of shapes. These shapes encompass sheets, plates, tubes, wires, or intricate three-dimensional structures. The capacity to mold aluminum coils into assorted forms renders it an exceptional choice for sectors such as construction, automotive, aerospace, and manufacturing, where customized parts and components are frequently required.

- Q:Are aluminum coils suitable for automotive body panels?

- Yes, aluminum coils are suitable for automotive body panels. Aluminum is lightweight, which helps improve fuel efficiency and overall vehicle performance. Additionally, aluminum is highly corrosion-resistant, making it an ideal choice for automotive applications where the panels are exposed to various weather conditions. Its high strength-to-weight ratio also provides excellent durability and crash resistance. Moreover, aluminum can be easily formed and shaped, allowing for intricate and stylish designs. Overall, the use of aluminum coils for automotive body panels offers numerous advantages and is a popular choice among car manufacturers.

- Q:How do aluminum coils compare to galvanized steel coils in terms of longevity?

- In terms of longevity, aluminum coils generally have a longer lifespan compared to galvanized steel coils. Aluminum is naturally resistant to corrosion, which means it is less likely to rust or deteriorate over time. This makes aluminum coils a popular choice for outdoor applications, such as in roofing, siding, and HVAC systems, as they can withstand harsh weather conditions without losing their structural integrity. On the other hand, galvanized steel coils are steel coils that have been coated with a layer of zinc to protect against corrosion. While this zinc coating provides some level of protection, it can wear off over time, particularly in areas with high humidity or exposure to saltwater. Once the zinc coating is compromised, the steel underneath becomes susceptible to rust and corrosion, which can significantly reduce the lifespan of galvanized steel coils. Therefore, if longevity is a primary concern, aluminum coils are generally a more durable and long-lasting option compared to galvanized steel coils. However, it is important to consider other factors such as cost, specific application requirements, and maintenance needs before making a final decision.

- Q:I don't have a rounded baking tray at the moment and would like to replace it with aluminium foil, do you think it's suitable and that it can withheld the intensity?

- Cheesecake batter is dense. An aluminium tray may not be stiff enough to retain the proposed shape of your cake. Test the pan; load it to the top with water. If it doesn't collapse your cheese cake will not either. You could try using two trays nestled together. You also may need to load the cake and tray on a flat tray when you move it around. Use a thermometer to know when the cake should be pulled. Cook's suggests the top limit at 150 degrees F. Do grease the sides of the pan. Be sure to loosen the cake from the pan side after it is out of the oven. I bake my cakes at 500 degrees F. for ten or twelve minutes, and then to the 150 degree F point at 200 degrees F. Do not open the oven or try to cool it down. Simply dial down the thermostat. If the cake looks too brown cover it with a piece of aluminium foil. Have fun! Avoid cracks...don't overcook the cake!

- Q:Can aluminum coils be used in the production of aluminum foam panels?

- Yes, aluminum coils can be used in the production of aluminum foam panels. The coils are typically processed through a foaming method, such as powder metallurgy or melt route, to create a foam structure. This allows for the production of lightweight and strong aluminum foam panels suitable for various applications, including in the automotive, aerospace, and construction industries.

- Q:Are aluminum coils suitable for construction applications?

- Yes, aluminum coils are suitable for construction applications. Aluminum is a lightweight and durable material that is widely used in the construction industry. Aluminum coils are often used for roofing, siding, gutters, and other exterior applications due to their resistance to corrosion and their ability to withstand harsh weather conditions. They are also easy to install and maintain, making them popular among contractors. Additionally, aluminum coils can be painted or coated to enhance their aesthetic appeal and to match the overall design of a building. Overall, aluminum coils are a reliable and cost-effective choice for construction applications.

- Q:I have my brother's old wooden crutches but i see everyone using aluminum and i have the option to get aluminum ones. Is there any reason why they'd be better then my wooden ones?

- Aluminum's are lighter and adjust more easily. To set the length on woodies, have have to twist off the wing nuts, position the lower end into the rods and replace and tighten the bolts. Aluminum's are adjusted merely by pressing the lock pins.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DC Process Aluminum Coil for Casting to Thinner Coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords