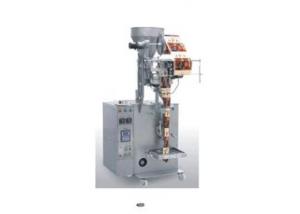

Chain-Bucket Automatic Packaging Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 10 Sets per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Usage of Chain-Bucket Automatic Packaging Machine

Suitable for packaging materials like all kinds of fried food, shrimp, sweets, chocolate, biscuit, seeds, frozen food, daily products, hardware and medicine.

Features of Chain-Bucket Automatic Packaging Machine

This is suitable for automatic packaging particle materials such as

Sweets, peanuts, nuts seeds, grain, coffee and tea.

Reasonable design, simple structure.

Controlled by single-chip computer, stepping motor, convenient

And correct bag length setting.

Simple, fast speed regulation.

Optional: Continuous-packaging control device, gas-filled device

(air source supplied by users).

Main technical datas of Chain-Bucket Automatic Packaging Machine

Packing speed 15-60bags/min

Bag-making size (L)60-250mm (W)60-180mm

Filling range 50-850ml

Packing materials OPP/CPP PET/PE

Film width 140-400mm

Film thickness 0.04-0.08mm

Film roll diameter Max. 320mm

Power supply AC220V 50Hz 2.5kw

Machine dimensions (L)1100× (W)820× (H)2150mm

Machine weight 400kg

- Q:Bag making machine cutting system

- 1, cutter: the system is the most important components, is the use of moving knife and sliding guide, by the spring compression of the floating mechanism, up and down the knife can be adjusted.

- Q:What is the filler

- Fill can be divided into two kinds of organic fillers and inorganic fillers, such as wood flour, rags, paper and a variety of fabric fibers, the latter such as glass fiber, diatomaceous earth, asbestos, carbon black and so on.

- Q:Watermarked non-woven bag production process

- Wash the plate without chemical solvents, can be washed directly with water.

- Q:What is the packing operation of the bag machine?

- 4, the total quality inspection staff to check the product according to the provisions of the proportion of pumping test, after passing the inspection package storage.

- Q:Cold cutting bag machine how to adjust the knife

- 2. When the use of a period of time after the plug iron gap increases should be immediately adjusted, then the first release of the nut, a little plug into the plug iron adjustment screw to the appropriate gap so far, and with a spike check, the gap should not be greater than 0.02mm

- Q:How to adjust the bag machine knife

- When the use of a period of time after the plug iron gap increases should be immediately adjusted, then the first release of the nut, a little plug into the plug iron adjustment screw to the appropriate gap so far, and with a spike check, the gap should not be greater than 0.02mm,

- Q:Bag machine before the start of the preparation

- 2, adjust the left and right folder roller, so that the left and right film alignment, adjust the front and rear folder roller, so that the pattern alignment.

- Q:The operating procedures of the bag machine

- 3, according to the production notice and process files to adjust the size of the bag, install a good heat sealing knife, and the initial tune the knife and heat sealing knife position.

- Q:What is the operation of the shutdown

- 3, make a duty record, require accurate, clean and tidy.

- Q:Three side seal characteristics

- 3, LPC automatic correction, double photoelectric tracking discharge, automatic constant tension control AC constant speed automatic feeding.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China (Mainland) |

| Year Established | 1996 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | 7.69% North America 7.69% South America 7.69% Eastern Europe 7.69% Southeast Asia 7.69% Africa 7.69% Oceania 7.69% Eastern Asia 7.69% Western Europe 7.69% Central America 7.69% Northern Europe 7.69% Southern Europe 7.69% South Asia |

| Company Certifications | CE License |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Hamburg, Jeddah, Mersin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 3,000-5,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Chain-Bucket Automatic Packaging Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Set m.t.

- Supply Capability:

- 10 Sets per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords