Ceramic Foam Filter for Foundry Stainless Steel Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Ceramic Foam Filters

Zirconia ceramic foam filters are mainly used to filter the steel and steel alloys required the higher temperature of 1780℃.It is strongly recommended to be used for high quality grades of steel alloys.

Features of Ceramic Foam Filters

Improving the steel casting quality

Excellent thermal shock resistance

High porosity with good strength

High efficiency to filter the steel dross

Tailored sizes as customer’s requirement

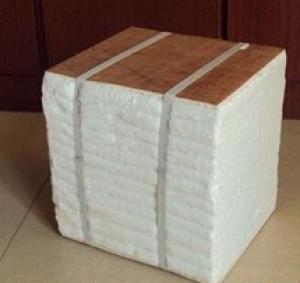

Image of Ceramic Foam Filters

FAQ

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q:Calcium silicate board white ICI belongs to wood surface paint?

- ICI can generally be considered as wall paint (latex paint), and latex paint can be used on this kind of cement board. And lumber is different, it is not suitable to brush latex paint on the surface of wood, it can only be decorated with paint (oil paint).

- Q:What is the main role of fly ash added in concrete products?

- The rational use of fly ash in concrete, not only can replace part of cement, reduce the construction cost, but also because of its unique properties can be effectively used for the various requirements of the use of concrete, improve and enhance the performance of concrete.

- Q:What's the difference between white carbon and carbon black? Can they be replaced?

- Carbon black is the floorboard of white powder X- ray of amorphous silica and silicate products, mainly refers to the precipitated silica, fumed silica, ultrafine silica gel and gel, including powder synthetic aluminium silicate and calcium silicate. Silica is a porous material, its composition by SiO2 nH2O, where nH2O is there the surface hydroxyl form. Soluble in caustic and hydrofluoric acid, insoluble in water, solvent and acid (except hydrofluoric acid). High temperature resistant, non flammable, tasteless, odorless, has the very good electric insulation.

- Q:What is the best price for the use of calcium silicate ceiling?

- Water will melt or become yellow, mildew. So if you choose their ceiling, you must first deal with the roof leak. Calcium silicate board with artificial and material prices of about 22 square meters, mainly for office space, and residential corridors and other public places decoration. Integrated ceiling is not afraid of water.

- Q:What are the raw materials of cement products? What's the function?

- Cement has a great influence on the properties of concrete. The kinds and quantities of cement containing minerals and the fineness of cement will affect the quality of cement products. The calcium silicate three in cement is an important factor in the coagulation of cement products. The reaction between three calcium silicate and water leads to the production of hydrated calcium silicate, and the hydrated calcium silicate gel acts as a cementing agent for aggregate and aggregate in concrete.

- Q:What are the new energy-saving building materials? What's new?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

- Q:What's the use of low carbon steel insulated nail hooks for power plants?

- The current power plant thermal insulation is mainly carried out by use of various types of insulation materials, thermal insulation materials commonly used include calcium silicate products, pipes, rock and aluminum silicate fiber products, due to their different properties are applicable to different environments. The equipment with temperature at 300-600 DEG C often adopts aluminium silicate products and calcium silicate products to compound heat preservation. While the temperature is less than 300 degrees, the mineral wool products are usually used for thermal insulation.

- Q:What are the high temperature resistant insulation materials at 400?

- Foam heat insulation material mainly includes two categories: polymer foam type insulation material and foam asbestos insulation material. Polymer foam heat insulation material has the advantages of small absorption rate, stable heat preservation effect, low thermal conductivity, no dust flying in construction, easy construction, and so on. It is in the period of popularization and application. Foam asbestos thermal insulation material has the characteristics of small density, good thermal insulation and convenient construction, and its popularization and development is relatively stable, and the application effect is better. But at the same time there are some defects: for example, foam cotton is easy to damp, immersed in water easily dissolved, elastic recovery coefficient is small, can not contact the flame and in the wall pipe parts use.

- Q:Eterpan with calcium silicate is sold on the market are the same thing? Non asbestos calcium silicate board is Eterpan it

- Aitken is a brand of non asbestos calcium silicate board is a product name

- Q:What is a building energy-saving materials?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ceramic Foam Filter for Foundry Stainless Steel Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords