Austenitic Seamless Steel Pipe 316L (00Cr17Ni14Mo2)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Austenitic Seamless Steel Pipe 316L Description:

Stainless Steel 316L Pipe is also known as austenitic stainless steel alloy. It offers tremendously high resistance to pitting and crevice corrosion in the chloride conditions. With its austenitic structure it imparts extremely high hardness even at low cryogenic temperature ranges. Stainless Steel 316L Pipe offers stress to rupture, large tensile strength and creeping resistance at the elevated temperature ranges.

2、Main Features of the Austenitic Seamless Steel Pipe 316L :

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Excellent weldability

• Highly tough

•Tremendous resistance to corrosion in the various media and oxidation

3、Austenitic Seamless Steel Pipe 316L Images:

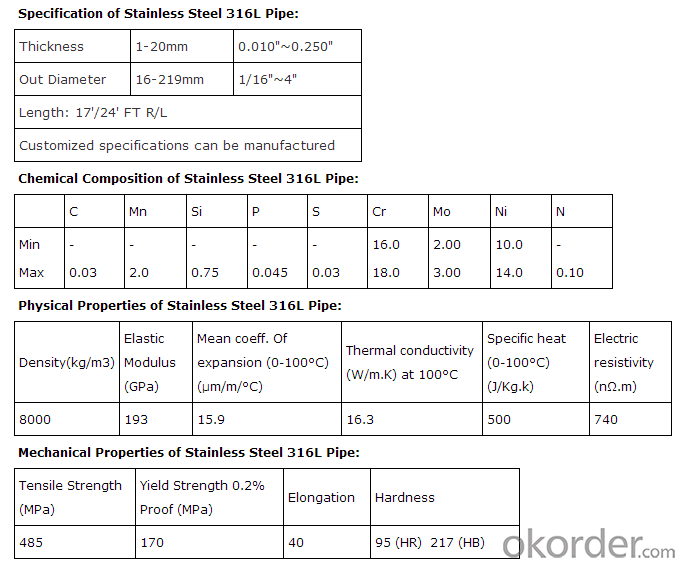

4、Austenitic Seamless Steel Pipe 316L Specification:

Product name: AISI stainless steel pipe/tube

Materials: 304, 304L, 310S, 316, 316L, 325, 273, 219 and 168

Thickness: 1, 2, 2.5, 3, 3.5, 4, 5, 6 and 8mm

Outer diameter: 6-480mm

Length: as required

Treatment: cold and hot rolled

Applications: construction upholstery, and industry instruments, such as fencing, railing,safe doors/windows, gate fittings, inside staircases, balcony balustrades, furniture, sanitary wares and kitchen wares

Standards: GB, AISI, ASTM, DIN and JIS

Sureface: 2B, BA and designer finishes

Price terms: FOB, CIF, CFR and EXW

Delivery:10-15 days after received the deposit or as quantity request.

Chemical Composition | C | Mn | P | S |

<=0.0< span="">3 | <=2.00< span=""> | <=0.0< span="">35 | <=0.03< span=""> | |

Si | Cr | N | Ni | |

<=1.00< span=""> | 16-18 | NO | 12-15 |

5、FAQ of Austenitic Seamless Steel Pipe 316L :

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

Any question, pls feel free to contact us !

- Q:What is the tensile strength of stainless steel pipes?

- The tensile strength of stainless steel pipes can vary based on the specific grade and composition of the steel. However, stainless steel is renowned for its high tensile strength, making it a popular choice for various applications that demand sturdy and long-lasting pipes. On average, stainless steel pipes possess a tensile strength that falls within the range of 500 to 1500 megapascals (MPa). Thanks to this remarkable tensile strength, stainless steel pipes can endure substantial pressure and stress, rendering them suitable for utilization in industries like construction, oil and gas, chemical processing, and automotive manufacturing. It is worth noting that the precise tensile strength of stainless steel pipes can be influenced by factors such as the manufacturing process, heat treatment, and any additional alloying elements present in the steel. Consequently, referring to the specific technical specifications or standards for the particular grade of stainless steel pipes is crucial in order to ascertain their exact tensile strength.

- Q:Are stainless steel pipes suitable for oil refineries?

- Stainless steel pipes, known for their high resistance to corrosion, prove to be a suitable choice for oil refineries. This is particularly important in environments abundant with corrosive substances like crude oil and various chemicals involved in refining procedures. Moreover, stainless steel pipes possess the ability to withstand both high temperatures and pressures, thus making them the perfect means for transporting oil and gas within the refinery. In addition to this, the low maintenance requirements and long lifespan of stainless steel pipes reduce the frequency of replacements, resulting in minimal downtime. In conclusion, stainless steel pipes offer the durability, reliability, and corrosion resistance necessary to meet the demanding conditions of oil refineries.

- Q:Are stainless steel pipes suitable for pharmaceutical applications?

- Yes, stainless steel pipes are highly suitable for pharmaceutical applications. Stainless steel is a corrosion-resistant material that meets the strict hygiene and cleanliness requirements of the pharmaceutical industry. It is non-reactive, easy to clean, and has excellent resistance to chemicals, making it ideal for transporting pharmaceutical products safely and maintaining their integrity. Additionally, stainless steel pipes can withstand high temperatures and pressures, ensuring the efficiency and reliability of pharmaceutical processes.

- Q:Can stainless steel pipes be embossed?

- Certainly, it is possible to emboss stainless steel pipes. Embossing refers to the technique of raising or pressing a pattern or design into a material like stainless steel, with the intention of creating a decorative or functional effect. This technique can be applied to a wide range of metal surfaces, including stainless steel pipes. To achieve this, specialized machinery and tools are employed to imprint the desired design onto the pipe's surface. The purpose of embossing can be twofold: it may enhance the visual appeal and texture for aesthetic reasons, or provide functional benefits like improved grip and slip prevention. In summary, embossing stainless steel pipes is indeed viable and can yield diverse desired outcomes.

- Q:Can stainless steel pipes be used for architectural purposes?

- Yes, stainless steel pipes can be used for architectural purposes. Stainless steel has several properties that make it suitable for architectural applications. Firstly, it is highly resistant to corrosion, which is important for structures exposed to the elements. Stainless steel pipes also have a sleek and modern appearance, which can add an aesthetic touch to architectural designs. Additionally, stainless steel is a strong and durable material, providing structural integrity and longevity to buildings. Its versatility allows it to be used in various architectural elements such as handrails, balustrades, staircases, and structural supports. Overall, stainless steel pipes are a popular choice for architectural purposes due to their combination of corrosion resistance, aesthetic appeal, and strength.

- Q:What is the welding of stainless steel?

- Sheet argon arc welding greater than 10mm by hand welding or gas shielded welding

- Q:Are stainless steel pipes suitable for hygienic applications?

- Yes, stainless steel pipes are suitable for hygienic applications. Stainless steel is widely used in industries such as food processing, pharmaceuticals, and dairy, where maintaining cleanliness and preventing contamination is crucial. Stainless steel pipes have several properties that make them ideal for hygienic applications. Firstly, stainless steel is highly resistant to corrosion, which is important for maintaining hygiene and preventing the growth of bacteria or other pathogens. It does not rust or corrode easily, even when exposed to various chemicals and cleaning agents used in hygienic environments. This resistance to corrosion ensures the integrity of the pipes and prevents any contamination from occurring. Secondly, stainless steel has a smooth, non-porous surface that is easy to clean and sanitize. The smoothness of the surface prevents the accumulation of dirt, bacteria, or other particles, making it easier to maintain a hygienic environment. Stainless steel pipes can be easily cleaned using various cleaning methods, including steam, high-pressure water, or chemical cleaning agents. Furthermore, stainless steel is a durable and long-lasting material. It can withstand high temperatures and pressures, making it suitable for a wide range of hygienic applications. Stainless steel pipes can be used for transporting fluids, gases, or other materials without compromising their hygienic properties. In addition, stainless steel is a non-reactive material, meaning it does not react with the substances it comes into contact with. This property is important for preventing any contamination or alteration of the substances being transported through the pipes. Overall, stainless steel pipes are highly suitable for hygienic applications due to their corrosion resistance, smooth surface, durability, and non-reactive properties. They provide a reliable and hygienic solution for industries where cleanliness and prevention of contamination are of utmost importance.

- Q:Can stainless steel pipes be used for brewery applications?

- Yes, stainless steel pipes can be used for brewery applications. Stainless steel is highly resistant to corrosion and can withstand the harsh conditions of a brewery environment, such as exposure to moisture and chemicals. It is also easy to clean and maintain, making it a suitable choice for transporting liquids in a brewery setting.

- Q:What is the average cost of stainless steel pipes?

- The cost of stainless steel pipes can differ based on several factors, including pipe size, grade, thickness, supplier, and location. Generally, stainless steel pipes may cost anywhere between $5 and $50 per foot. Nevertheless, it is crucial to acknowledge that prices may vary due to market conditions and other influences. To obtain a more precise estimate for the required stainless steel pipes' specific type and quantity, it is advisable to conduct thorough research and compare prices from various suppliers.

- Q:Are stainless steel pipes resistant to pitting?

- Stainless steel pipes possess a high level of resistance against pitting. Pitting corrosion, a localized type of corrosion, leads to the formation of small holes or pits on metal surfaces. Stainless steel, consisting of chromium as its primary alloying element, develops a passive oxide layer when exposed to oxygen. This layer acts as a protective barrier that hinders further corrosion, thus ensuring stainless steel pipes' excellent resistance to pitting. Additionally, stainless steel pipes often incorporate other elements like molybdenum or nickel, which further improve their pitting resistance. Consequently, stainless steel pipes emerge as a dependable choice for applications where withstanding pitting corrosion is imperative, such as marine environments or chemical processing industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Austenitic Seamless Steel Pipe 316L (00Cr17Ni14Mo2)

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords