Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

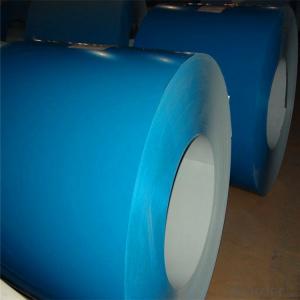

Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

Description of Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q:Can special steel be used for electrical applications?

- Yes, special steel can be used for electrical applications. Special steel alloys, such as stainless steel or electrical-grade steels, are often used in electrical applications due to their excellent electrical conductivity, resistance to corrosion, and high strength properties. These steels are commonly utilized in the manufacturing of electrical components, wiring, transformers, and various electrical equipment.

- Q:What are the different methods of surface lapping for special steel?

- There are several different methods of surface lapping for special steel. These methods are used to achieve a high level of flatness and smoothness on the surface of the steel. One common method is called free abrasive lapping. In this method, a slurry containing abrasive particles is used to polish the surface of the steel. The slurry is typically applied to a rotating lap plate, which is then pressed against the steel surface. The abrasive particles remove material from the surface, resulting in a smoother and flatter surface. Another method is called fixed abrasive lapping. In this method, a rigid lap plate with abrasive particles embedded in it is used to polish the steel surface. The lap plate is typically made of a harder material than the steel being lapped. As the lap plate rotates and is pressed against the steel surface, the embedded abrasive particles remove material, resulting in a smoother surface. Chemical lapping is another method that can be used for special steel. In this method, a chemical solution is applied to the steel surface. The chemical solution reacts with the surface of the steel, dissolving and removing a thin layer of material. This method is often used when a high level of flatness is required. Ultrasonic lapping is a method that uses ultrasonic vibrations to enhance the lapping process. In this method, the steel surface is placed in contact with a bath of abrasive particles and a liquid medium. Ultrasonic vibrations are then applied to the liquid medium, causing the abrasive particles to vibrate and remove material from the surface of the steel. This method can be particularly effective for lapping hard and brittle materials. Overall, the different methods of surface lapping for special steel offer various approaches to achieve the desired level of flatness and smoothness. The selection of the method depends on factors such as the type of steel, the desired surface finish, and the specific requirements of the application.

- Q:What are the factors that affect the weldability of special steel?

- The factors that affect the weldability of special steel include the chemical composition of the steel, the presence of impurities or alloying elements, the heat treatment history, the thickness of the steel, the welding process and technique used, and the pre-weld and post-weld treatments.

- Q:How does tool steel maintain its hardness at high temperatures?

- Tool steel maintains its hardness at high temperatures due to its high carbon content and the presence of alloying elements such as tungsten, molybdenum, and vanadium. These elements form carbides, which enhance the steel's ability to retain its hardness even under extreme heat. Additionally, the steel's fine grain structure and heat treatment processes contribute to its high temperature hardness retention.

- Q:What are the applications of special steel in the nuclear industry?

- Special steel is extensively used in the nuclear industry due to its unique properties. It is used to manufacture various components such as reactor vessels, steam generators, and fuel cladding, which require high strength, corrosion resistance, and heat resistance. Special steel ensures the safety and efficiency of nuclear power plants by withstanding extreme temperatures, pressures, and corrosive environments. Its applications in the nuclear industry are crucial for maintaining the integrity and reliability of nuclear facilities.

- Q:What are the challenges in recycling special steel?

- One of the main challenges in recycling special steel is the complexity of its composition. Special steel often contains various alloying elements and additives that can make the recycling process more difficult. These elements need to be carefully identified and separated in order to maintain the desired properties of the recycled steel. Additionally, special steel may have undergone specific heat treatments or surface coatings, which further complicate the recycling process. Proper sorting, identification, and treatment techniques are necessary to overcome these challenges and ensure the successful recycling of special steel.

- Q:What is the chemical composition of special steel?

- Special steel is a type of steel that is specifically manufactured for particular applications, and its chemical composition varies depending on its intended use. However, some common elements found in special steel include iron, carbon, manganese, chromium, nickel, and molybdenum. The precise combination and quantities of these elements are carefully balanced to achieve specific properties such as enhanced strength, corrosion resistance, or heat resistance, making special steel ideal for specialized applications in industries like aerospace, automotive, and construction.

- Q:How does special steel contribute to the manufacturing of surgical instruments?

- Special steel, which is also known as stainless steel, plays a vital role in the production of surgical instruments. Its exceptional properties make it an ideal material for manufacturing high-quality surgical instruments used in various medical procedures. To begin with, special steel exhibits a high resistance to corrosion and rust. Surgical instruments are constantly exposed to bodily fluids, sterilization processes, and harsh cleaning agents. The corrosion resistance of special steel guarantees the durability of these instruments, enabling them to withstand repeated use and cleaning without compromising their integrity. Furthermore, special steel possesses excellent strength and hardness characteristics. Surgical instruments must be robust and capable of withstanding the forces and pressures exerted during surgeries. The high strength and hardness of special steel ensure that these instruments retain their shape and sharpness even after multiple uses, minimizing the risk of breakage or deformation during critical procedures. Moreover, special steel is biocompatible, meaning it does not elicit reactions or complications when in contact with bodily tissues or fluids. This is particularly important for surgical instruments that come into direct contact with patients' bodies. The biocompatibility of special steel guarantees that there are no adverse reactions or complications when these instruments are used in surgeries, thereby reducing the risk of infections or other complications. In addition, special steel is highly machinable and can be easily molded into intricate shapes and designs. Surgical instruments require precision and accuracy to effectively fulfill their intended functions. The machinability of special steel allows manufacturers to create complex instruments with fine details and features, ensuring their optimal performance during surgical procedures. Furthermore, special steel can be efficiently sterilized. Sterilization is a critical step in ensuring the safety and effectiveness of surgical instruments. Special steel's ability to withstand high temperatures and various sterilization methods, such as autoclaving or ethylene oxide gas sterilization, makes it an ideal choice of material for surgical instruments. In conclusion, special steel significantly contributes to the manufacturing of surgical instruments due to its corrosion resistance, strength, biocompatibility, machinability, and sterilization capabilities. These properties guarantee that surgical instruments made from special steel are durable, reliable, safe, and effective in medical procedures, ultimately enhancing the success of surgeries and improving patient outcomes.

- Q:How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through several ways. Firstly, special steel is known for its excellent strength and durability, which allows manufacturers to design products with thinner and lighter components. This reduction in material usage directly leads to cost savings without compromising on quality. Additionally, special steel possesses unique properties such as corrosion resistance, heat resistance, and wear resistance. By using special steel, manufacturers can create products that have a longer lifespan and require less maintenance or replacement. This not only reduces the overall cost of ownership for customers but also enhances the reputation of the brand for delivering reliable and high-quality products. Furthermore, special steel often allows for improved manufacturing processes, such as easier machinability or better weldability, which can result in increased efficiency and reduced production time. These time and cost savings can be passed on to the customers, making the final product more affordable without sacrificing quality. In summary, special steel's strength, durability, unique properties, and improved manufacturing processes contribute to cost reduction while maintaining or even enhancing product quality.

- Q:How is stainless steel used in the food and beverage industry?

- Stainless steel is widely used in the food and beverage industry due to its excellent properties such as corrosion resistance, durability, and hygienic qualities. It is commonly used for manufacturing food processing equipment like tanks, pipes, and storage containers, as well as kitchen appliances and utensils. The non-reactive nature of stainless steel ensures that it does not impart any unwanted taste or odor to the food or beverage being processed or stored, making it a safe and ideal choice for maintaining product quality and safety standards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluzinc PPGI Exterior Decorative Prepainted Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords