Aluminum Strip for Pharmaceutical Bottle Cap

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description

Aluminum strip is widely used in industry, such as packaging & building industry. Because the good anti heat and anti wet specification. it's very good for pharmaceutical bottle caps. Normally it's coated lacquer, coating thickness is around 4~5mic.

2.Specification and Application

Specification

| Alloy | 8011 |

| Temper | H12/ H14/ H16 |

| Process | DC |

| Thickness | 0.17~0.25mm |

| Width | As required |

| Core ID | As required |

Property

| Tensile strength | ≥120Mpa |

| Elongation | ≥2% |

| Tolerance of size | As GB Standard |

3. Advantages

We've been specialized in aluminium for more than ten years, we know this product very well, and we have good finacial support from government. And also flexible payment term and fast delivery.

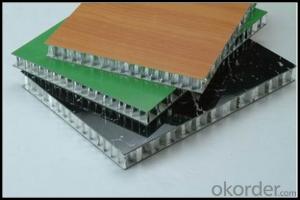

4. Pictures

5. FAQ

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your minimum order quantity?

It's 3tons per size.

- Q:What gas is best for welding aluminum strip?

- If you are using the gas, liquefied gas gun can be used separately burning liquefied petroleum gas welding, then burning gas is liquefied gas, but this time need to use low temperature welding wire, such as the WEWELDING M51 with WEWELDING M51-F solder welding wire.

- Q:What is the relationship between the aluminum plate, the aluminum foil and the aluminum alloy strip?

- According to the domestic and SWA northeast light interpretation of this concept refers to the use of aluminum strip rolling mill for rolling plate after the coil of strip or stripe after, in a foreign country is divided into plate and sheet, a domestic sheet and plate.

- Q:What kind of mask is good for welding aluminum strips?

- The welding aluminum strip will produce certain peculiar smell and aluminum chip. Can solve this problem at the same time, activated carbon mask can solve, activated carbon can absorb some peculiar smell, at the same time can come dust.

- Q:What's the specialty of aluminum strip rolling?

- Now, metal pressure processing profession, undergraduate course is called material forming and control major, master and doctor stage is called material processing engineering.

- Q:How does the excavator aluminum belt turn in place?

- This is how it works1. Support the front half of the track with the bucket, so that half or more of the track is out of the ground2, turn the operating lever in the opposite direction of the desired turn, and then turn the track

- Q:What is the difference between cold rolling and hot rolling of aluminium plate and aluminium strip? Which kind of aluminum plate is good? Speak a little more popularly

- Cold rolled, no hot rolled aluminum sheet, good surface. It doesn't make much difference if you don't ask for it. Hot rolled aluminum plate is suitable for oxidation. The oxidation effect will be much better.

- Q:1060 what is the hardness of aluminum strip?

- Brinell hardness measurement method is to use a hardened steel ball, such as the diameter of 5 mm steel ball, with a certain force into the parts or material surface, and then measure the indentation size, read the hardness value.

- Q:Classification of aluminium strips of aluminium strips

- Aluminum strip is a strip of aluminum ingot obtained by press rolling, according to the use of different grades, specifications, status. The aluminum belt has many uses, such as: aluminum plastic composite pipe, cable, fiber optic cable, transformer, heater, shutter and so on. The processing technology of aluminum strip is the aluminum deep processing product formed by the slitting and slitting of aluminum rolls. It is an important raw material in industry. According to the aluminum alloy containing aluminum and aluminum with different origin, the same is also divided into 8 series. However, the commonly used series for the 100030005000 and 8000 Series, depending on the annealing state of the aluminum strip, the aluminum strip can be divided into fully soft (o), semi hard (H24) hard (h18). At present, the most commonly used should belong to the whole soft series, because the O state is easier to stretch and bend. The main processing equipment of aluminum strip is a strip mill, which can be divided into required length and width according to need. Of course, the processing equipment is universal, copper coil can also be processed, processed products known as copper strip. At present, the international raw materials for electronic products are no longer purely dependent on copper strip. As the conductivity of aluminum is only lower than copper, the aluminum strip instead of copper strip is becoming a popular trend in the world. The classification of aluminium tapes includes pure aluminium belt, transformer, aluminium belt, super hard aluminium belt, full soft aluminium belt, semi hard aluminium belt and antirust aluminium belt.

- Q:Use of aluminium strips for aluminium strips

- 1060 requirements of corrosion resistance and formability are high, but the strength requirements are not high, chemical equipment is its typical use1100 for processing requires good formability and high corrosion resistance but is not required to have high strength parts, such as chemical products, food industry device and storage containers, sheet processing, deep drawing or spinning concave ware, welding parts, heat exchanger, printing plate, nameplate, reflective instruments3004 plates, thick plates, tensile tubes. For as long as extruded tube aluminum cans cans, requires much higher than the 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.

- Q:What is the best capacitance for an aluminum ribbon tweeter?

- You can choose to ask questions in the right category so that you know more questions and answer more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Strip for Pharmaceutical Bottle Cap

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 Tons m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords