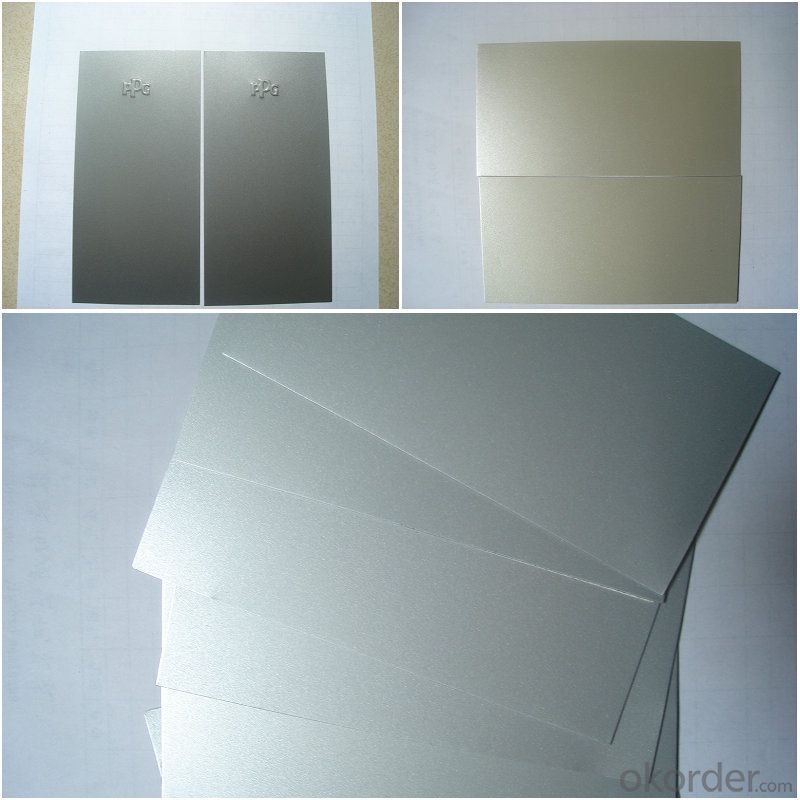

Aluminum coating coils Champagine silver color coated

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Featuresof PVDF Aluminum Coil:

1. Adoptingprecision rolling coating technology, our PE coated coil can ensure excellentadhesive without coating omission.

2. For the PVDFcoated aluminum sheet we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

Raw Materialof the PVDF Coated Aluminum Coil:

1. AluminumCoil: high strength aluminum with alloy of AA1100 (aluminum alloy is availablewith AA3003, AA3005, AA5005 according to customer)

2. SurfacePaint: PE, PVDF and special paints.

Specificationof the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

ExternalDiameter: ≤ 1500mm

InternalDiameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

Performance and usage

PVDF coated aluminumcoils are specially processed through the technics of roller coating and bakingwith precise paints from BECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color ofCard

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

- Q:Can aluminum coils be painted for custom designs?

- It is indeed possible to paint aluminum coils to achieve personalized designs. The act of painting the coils opens up a world of limitless options for customization and aesthetic appeal. Various colors, patterns, and designs can be applied to the coils, catering to individual tastes and needs. To complete the painting process, the surface must first be cleaned, followed by the application of a primer and the desired paint or coating. Through this method, one can create distinctive and captivating custom designs suitable for a wide array of purposes, including architectural elements, signage, automotive components, and more. Moreover, the paint not only safeguards the aluminum from corrosion but also enhances its durability.

- Q:How do aluminum coils compare to plastic coils in terms of durability?

- Aluminum coils generally offer superior durability compared to plastic coils. Aluminum is a highly durable material known for its strength and resistance to wear and tear. It can withstand heavy usage and is less likely to crack, break, or deform under pressure. On the other hand, plastic coils may be more prone to damage, especially when subjected to repetitive use or extreme temperatures. While plastic coils can be cost-effective and lightweight, they may not hold up as well over time. Therefore, if durability is a priority, aluminum coils are a better choice as they offer a longer lifespan and greater resistance to damage.

- Q:Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications due to their excellent thermal conductivity properties.

- Q:Are aluminum coils affected by magnetic fields?

- Yes, aluminum coils can be affected by magnetic fields to a certain extent. Aluminum is a non-magnetic material, meaning it does not possess any inherent magnetic properties. However, when exposed to strong magnetic fields, aluminum can experience an induced magnetic field due to a phenomenon called electromagnetic induction. This can result in a slight attraction or repulsion between the aluminum coil and the magnetic field, although the effect is generally weaker compared to materials with magnetic properties, such as iron or steel. It is important to note that the degree of interaction between aluminum coils and magnetic fields depends on several factors, including the strength and proximity of the magnetic field, the shape and size of the coil, and the specific composition of the aluminum alloy used in the coil.

- Q:Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be used for electrical transmission lines.

- Q:Can aluminum coils be coated with protective films?

- Yes, aluminum coils can be coated with protective films. These films are typically made of a variety of materials, such as polyester or polyethylene, and are applied to the aluminum coils using adhesive or heat bonding. The purpose of these protective films is to prevent damage, scratches, or corrosion to the surface of the aluminum coils during storage, transportation, or processing. The films act as a barrier, shielding the coils from external factors such as moisture, dirt, or chemicals. Additionally, certain protective films can also provide temporary UV protection. Overall, coating aluminum coils with protective films is a common practice in various industries to ensure the quality and integrity of the coils are maintained throughout their handling and use.

- Q:Aluminum roll width 750mm, single layer thickness 6.5mm, diameter 400mm., how to calculate the weight of the aluminum roll?

- You can use the outside diameter, the inner diameter and the width to get the volume. You know the density and volume, and then you can find the weight naturally

- Q:Should the aluminum roll be in the direction of the aluminum roll length or width?

- Grade two subgrade width is 10.0m. When setting up the slow lane, the width of the new standard subgrade is 15m and 12m respectively, while the original standard is 17.0m, corresponding lane 14.0m.Provincial standard is 20m, but must be hard shoulder, the corresponding pavement width of 10.5m, 8.5m.The highway bridge, a special highway, using integrated superstructure, median and shoulder width of appropriate narrow, but should not be less than the minimum value of the corresponding standard 28m subgrade, bridge deck width is 26m.

- Q:How do aluminum coils contribute to thermal insulation?

- Aluminum coils contribute to thermal insulation by acting as a barrier to prevent the transfer of heat. They are typically used in insulation systems to create a reflective surface that reflects radiant heat away from the desired area, thus reducing heat transfer and improving energy efficiency. Additionally, aluminum coils are lightweight, durable, and have good conductivity properties that help in maintaining stable temperatures and minimizing heat loss or gain.

- Q:Are aluminum coils resistant to moisture?

- Yes, aluminum coils are resistant to moisture. Aluminum is inherently corrosion-resistant, which means it has a natural ability to resist the effects of moisture and other environmental factors. This makes it an excellent choice for applications where moisture resistance is crucial, such as in HVAC systems, refrigeration units, and outdoor equipment. Additionally, aluminum can be further protected with a variety of protective coatings and treatments to enhance its resistance to moisture and extend its lifespan. Overall, aluminum coils are known for their durability and ability to withstand moisture, making them a reliable choice in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum coating coils Champagine silver color coated

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords