Aluminium Alloy Profile for Window and Door in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Alloy Profile for Window and Door Description:

Aluminium Alloy Profile for Window and Door(also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Alloy Profile for Window and Door:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

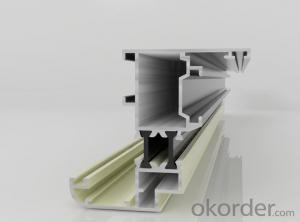

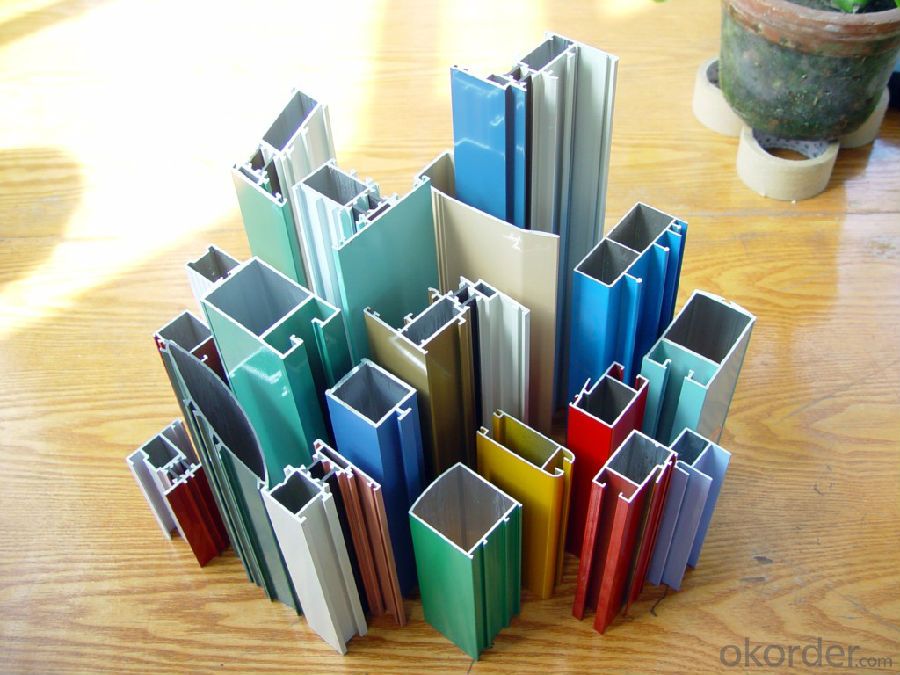

3.Aluminium Alloy Profile for Window and Door Images:

4.Aluminium Alloy Profile for Window and Door Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What is the role of aluminum coils in the construction of power plants?

- Aluminum coils are commonly used in power plants for the construction of heat exchangers and condensers. These coils play a crucial role in facilitating the transfer of heat and efficiently cooling fluids within the power plant system. The lightweight and corrosion-resistant nature of aluminum makes it an ideal material choice for these applications, ensuring optimal performance and longevity of the power plant equipment.

- Q:Can aluminum coils be used for gutter systems?

- Indeed, gutter systems can employ aluminum coils. The lightweight property, durability, and resistance to rust and corrosion make aluminum a favored material for gutters. It is common practice to utilize aluminum coils to shape seamless gutters, which present benefits such as reduced leakage and an enhanced visual appeal. Moreover, maintaining aluminum gutters is effortless, and they can be painted to harmonize with a building's exterior. All in all, aluminum coils are a fitting and frequently employed option for gutter systems.

- Q:Can aluminum coils be used for architectural applications?

- Yes, aluminum coils can be used for architectural applications. Aluminum is a versatile and lightweight material that is commonly used in construction due to its durability, corrosion resistance, and ease of installation. It can be formed into coils and used for various architectural elements such as roofing, cladding, facades, gutters, and window frames.

- Q:Can aluminum coils be customized to specific requirements?

- Indeed, specific requirements can be accommodated through customization of aluminum coils. The versatility of aluminum coils allows for a broad range of specifications and applications to be met. Customization options encompass alloy selection, coil thickness, width, and length, as well as diverse surface treatments like coatings, finishes, and embossing. Furthermore, mechanical properties such as strength, flexibility, and corrosion resistance can be tailored to individual needs. To achieve desired outcomes, close collaboration with manufacturers or suppliers possessing the necessary expertise and facilities is necessary. Whether for the aerospace industry, automotive sector, construction projects, or any other usage, aluminum coils can be tailor-made to fulfill specific requirements and deliver optimal performance.

- Q:Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a widely used material in the food industry due to its excellent properties such as its lightweight, durability, corrosion resistance, and heat conductivity. These qualities make aluminum coils suitable for various applications in food storage facilities. Aluminum coils can be utilized in refrigeration systems, air conditioning units, and food storage cabinets, among others. Additionally, aluminum is non-toxic and does not react with food or alter its taste, making it a safe option for food storage. However, it is important to ensure that the aluminum coils used in food storage facilities are properly cleaned and maintained to prevent any potential contamination.

- Q:Are aluminum coils suitable for heat exchanger applications?

- Yes, aluminum coils are suitable for heat exchanger applications. Aluminum is a lightweight and highly conductive material, making it an excellent choice for heat transfer applications. Aluminum coils offer several advantages in heat exchangers, such as high thermal conductivity, corrosion resistance, and ease of fabrication. They are commonly used in various heat exchanger systems, including air conditioning, refrigeration, and automotive applications. Additionally, aluminum coils can be easily formed into different shapes and sizes, allowing for greater design flexibility. Overall, aluminum coils are a reliable and efficient option for heat exchanger applications.

- Q:What is the typical heat transfer coefficient for aluminum coils?

- The heat transfer coefficient for aluminum coils can vary depending on several factors, including the application, coil geometry, and surrounding conditions. Generally, aluminum has high thermal conductivity, which enables efficient heat conduction. In forced convection applications, where heat is transferred using a fluid like air or water, the heat transfer coefficient for aluminum coils can range from 10 to 100 W/m^2K. This range is influenced by factors such as flow rate, velocity, and temperature difference between the coil and the fluid. In natural convection scenarios, where heat transfer occurs due to the buoyancy-driven flow of air, the heat transfer coefficient for aluminum coils is typically lower, ranging from 5 to 25 W/m^2K. This is because the movement of air is slower and the heat transfer effectiveness is reduced compared to forced convection. It's important to note that these values are general guidelines and can vary significantly depending on specific design considerations, material properties, and operating conditions. Therefore, it is recommended to consult specific heat transfer data or conduct detailed experiments or simulations to determine the precise heat transfer coefficient for a given aluminum coil application.

- Q:Can aluminum coils be used for thermal insulation purposes?

- Thermal insulation purposes cannot be fulfilled by aluminum coils, as it is a metal with high thermal conductivity, facilitating heat transfer. Consequently, instead of preventing it, utilizing aluminum coils as thermal insulation would actually facilitate the transfer of heat. To achieve effective thermal insulation, materials such as fiberglass, foam, or mineral wool, which possess low thermal conductivity, are commonly employed. These materials establish a barrier that restricts heat transfer, thereby maintaining the desired temperature within a given space.

- Q:Can aluminum coils be used for electrical transformers?

- Yes, aluminum coils can be used for electrical transformers.

- Q:I HEARD THAT ALUMINUM POWDER TIGHTEN YOUR VAGINA BUT WHERE DO I BUY IT AND HAVE ANY ONE HEARD OF BEYDARY PILLS, I HEARD THEY TIGHTEN YOUR VAGINA ALSO AND WHERE CAN I BUY THEM

- try leaving it alone for awhile

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Alloy Profile for Window and Door in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords