Acoustic Fiberglass Wall Panel for Cinema

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Description

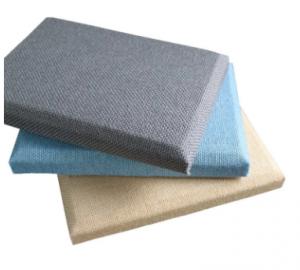

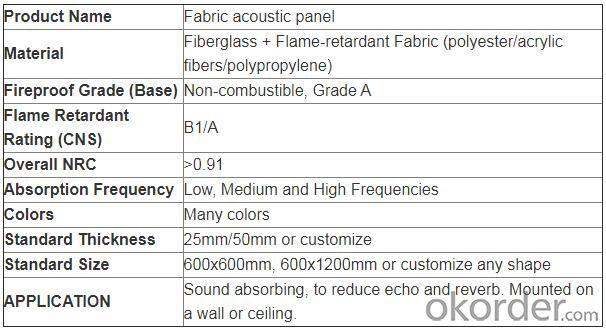

Fiberglass Acoustic Wall Panels are made of acoustic fiber and fabric or leather on surface, have excellent soundproof performance in both mid and high frequency. They are decorative and easy to installed. The fabrics on the surface are available in different colors and patterns. Customized is acceptable, you can also provide your own fabrics and designs.

Specification

Application

It is recommended that the Fiberglass Acoustic Wall Panels be installed to the opposite two walls to control the echo of the surroundings. The panels are widely used in Commercial Halls, Classrooms, Offices, Librairies, Shopping Centers, Music Rooms, Auditoriums, etc.where have special request for sound absorption.

Product Features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q:Glass fiber mesh quality soft and hard for the wall, which is better?

- The softness of the mesh cloth does not depend on the quality of the mesh cloth. Depending on how much glue is applied. Used in the wall, of course, is a lot of glue, and can increase the degree of alkali resistance. Now there is a kind of urine glue, painted out really hard But this is not alkaline.

- Q:The difference between GRC lightweight partition board and ceramic plate

- GRC lightweight partition board: glass fiber reinforced cement to do the board; GRC has a thin structure, high resistance to stretch, good impact resistance, low alkalinity, free expansion rate of small crack performance and reliable, stable quality, moisture, It is easy to avoid the wet construction, improve the construction environment, save the land resources, light weight in the building to reduce the load, (is the Clay brick 1 / 6-1 / 8 weight) to reduce the foundation and beam, Zhu reinforced concrete, reduce the total cost of the project, expand the use of area. Is the non-load-bearing parts of the building to replace clay brick the best material

- Q:Grc light partition board construction steps is what

- Clean up construction operations In order to ensure the smooth construction of the GRC lightweight partition board, clean up the cleaning parts of the partition board in time and remove the debris from the ceiling, the wall and the mortar blocks protruding from the cylinder, and then rinse the upper part with water Of the floating ash and sand, and dry, and then check the flatness of the site to ensure that the floor of the ground formation, for high and low depression more than 40mm parts should be leveling.

- Q:What is the quality of the light barrier now?

- . Increased use of building area: the wall can increase the use of an area of 8-10% or more, is the property development buyers and sellers are happy to accept.

- Q:Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q:How to do with glass fiber wall anti-crack

- First look at what is the wall, is the load-bearing walls, non-load-bearing walls, as well as the original wall is now there are cracks? Do the best way to do anti-crack wall is to shovel the original wall shovel, a plaster leveling or low-level gypsum leveling, after drying in the use of ecological white latex patch, cloth to use really good, so you can prevent the wall The surface is cracked.

- Q:Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- If the insulation from the good, corrosion-resistant aspects to consider, then the inorganic glass fiber reinforced plastic composite panel better, for the following reasons: Inorganic glass fiber reinforced high temperature. (Under normal circumstances, the temperature of 400 degrees Celsius to keep the product is not deformed). Inorganic glass steel anti-aging, 20 years the product is not deformed. Clean air, can absorb air of carbon dioxide. high strength. Good waterproof performance. Light weight, second only to plexiglass steel. Low cost, low price of raw materials floating. Insulation, sound absorption. Not burning After disposal, it can be used for landfill. It is an ideal environmental protection material for water, soil and air.

- Q:What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q:Is the interior wall made of fiberglass mesh good or wire mesh?

- If only the local cracks, you can also use ordinary straps paste.

- Q:What is GRC and can I paint it?

- GRC is also called grc components, refers to the fiberglass made of component-type material, grc shape is based on the external wall of the cad drawings to design, generally do not recommend making paint, grc's exterior decoration has its own treatment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Acoustic Fiberglass Wall Panel for Cinema

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches