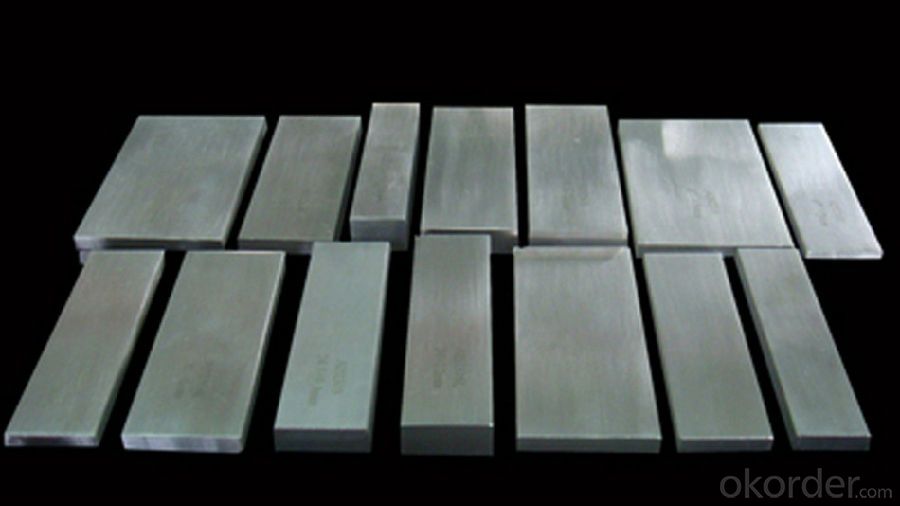

8.79KG/M steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering 8.79KG/M steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

8.79KG/M steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel Flat Bar for construction are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: slited

Slitting precision (width) : 0.5 mm or less

Raw material: Q235B, Q345B, Q235-1 b

crosscutting precision (length) : 2 mm or less

Processing: the thickness of 2.0-16 mm;

Shear length: 2000 mm above

Wide degree: 15-1250 - mm;

Leveling precision: 1-2 MM square

Packaging: Export packing, nude packing, bundled

The Carbon Steel Flat Bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q:How to grounding lightning protection grounding?

- In the cupboard and a MEB box, distribution box shall be the total PE bus, building low voltage power distribution cabinet. The 2 main vertical bars in the column are used for grounding on the line when the potential is grounded, and then the hot galvanized flat steel is led to each LEB terminal box with 40*4. In the elevator shaft from the elevator pit 0.2 meters, and the elevator shaft end below each embedded 100*100*8 hot galvanized flat steel piece, flat steel and column 2 as the main vertical grounding line and welding.

- Q:Can steel flat bars be used for making frames or supports for signs?

- Yes, steel flat bars can be used for making frames or supports for signs. Steel flat bars are versatile and strong, making them ideal for providing structural support. They can be easily cut, bent, and welded to create custom frames of various shapes and sizes. The robust nature of steel makes it suitable for outdoor applications, as it can withstand harsh weather conditions and provide long-lasting durability. Additionally, steel flat bars can be painted or coated to enhance their aesthetic appeal and protect them from corrosion. Overall, steel flat bars are a popular choice for constructing frames or supports for signs due to their strength, versatility, and ability to withstand different environmental factors.

- Q:Can steel flat bars be used for creating shelving or storage systems?

- Yes, steel flat bars can be used for creating shelving or storage systems. Steel flat bars are commonly used in construction and industrial applications due to their strength and durability. They can be easily welded or bolted together to create sturdy shelving structures, providing an efficient and reliable storage solution.

- Q:How do steel flat bars perform in corrosive or acidic environments?

- Corrosive or acidic environments can affect the performance of steel flat bars, depending on the type of steel and the specific properties of the environment. For instance, stainless steel flat bars offer high resistance to corrosion in most acidic or corrosive environments. This is due to their chromium content of at least 10.5%, which forms a protective oxide layer on the steel surface, preventing further corrosion. Moreover, stainless steel flat bars can be alloyed with elements like nickel or molybdenum to further enhance their corrosion resistance. On the other hand, carbon steel flat bars are not as resistant to corrosion. They are prone to rust and corrosion in acidic or corrosive environments because they lack the protective oxide layer present in stainless steel. In such cases, additional measures like galvanization or coating the flat bars with corrosion-resistant materials may be necessary for protection. To determine the performance of steel flat bars in corrosive or acidic conditions, it is crucial to consider the specific type of steel used and the nature of the environment. Seeking advice from experts or referring to corrosion resistance charts can provide more precise information regarding the suitability of steel flat bars in different environments.

- Q:What is the cost of steel flat bars?

- The cost of steel flat bars can vary depending on various factors such as the grade of steel, the size and thickness of the bars, and the quantity being purchased. Generally, the price range for steel flat bars can be anywhere from $10 to $50 per bar. However, it is important to note that these prices are just estimates and can vary significantly depending on the current market conditions and the specific suppliers. To get an accurate cost, it is recommended to contact local steel suppliers or check online marketplaces for the most up-to-date prices.

- Q:Why is it better to use round steel than that of flat steel in lightning protection?

- Exposed on the outside with round steel, due to corrosion of small, dark buried flat steel, because of large welding area, reliable connection.

- Q:How do steel flat bars perform under static loads?

- Steel flat bars are known for their excellent performance under static loads. Due to their high strength and stiffness, they are able to withstand heavy weights without undergoing any significant deformation or failure. The uniformity and consistency of steel flat bars also contribute to their reliable performance, making them a popular choice in various structural and construction applications.

- Q:Are steel flat bars suitable for automotive applications?

- Yes, steel flat bars are suitable for automotive applications. Steel is a strong and durable material that can withstand the rigorous demands of the automotive industry. Flat bars are commonly used in automotive applications due to their versatility and ease of use. They can be easily cut, shaped, and welded to fit specific automotive components, making them ideal for frame construction, brackets, supports, and other structural parts. Additionally, steel flat bars provide excellent strength-to-weight ratio, corrosion resistance, and cost-effectiveness, making them a popular choice in the automotive industry.

- Q:How do steel flat bars contribute to the overall stability of a structure?

- Steel flat bars contribute to the overall stability of a structure in several ways. Firstly, these bars are known for their high tensile strength, which means they can resist large amounts of force without easily bending or breaking. This strength allows them to provide structural support and prevent the structure from collapsing under heavy loads or external pressures. Additionally, steel flat bars are often used as braces or reinforcements in construction. They can be strategically placed and welded to different parts of the structure to increase its rigidity and prevent any potential deformations. By distributing the load more evenly, these bars help in maintaining the structural integrity and preventing any unwanted movements or vibrations. Moreover, steel flat bars are highly durable and resistant to corrosion, making them suitable for long-term use in various environments. This durability ensures that the structure remains stable and safe over time, even in harsh conditions or exposure to moisture or chemicals. Furthermore, the versatility of steel flat bars allows them to be used in a wide range of structural applications. Whether it's for beams, columns, trusses, or even as a base for other components, these bars provide stability and support to different parts of the structure. They can be easily customized and fabricated to meet specific design requirements, ensuring that the structure is built to withstand the intended loads and forces. In conclusion, steel flat bars play a crucial role in enhancing the overall stability of a structure. Their high tensile strength, ability to resist deformation, durability, and versatility make them indispensable components in construction projects. By providing support, reinforcement, and resistance to external forces, these bars contribute significantly to the structural integrity and safety of the overall built environment.

- Q:How do steel flat bars compare to other types of steel bars?

- Steel flat bars, a type of steel bar widely used and known for their versatility, possess numerous advantages when compared to other types of steel bars. To begin with, steel flat bars provide a larger surface area compared to round bars or square bars. This expansive surface area renders steel flat bars ideal for applications requiring strength and stability, such as construction or industrial projects. Moreover, the increased surface area allows for better weight and stress distribution, resulting in steel flat bars exhibiting superior resistance to bending or warping under heavy loads. Furthermore, steel flat bars are easily fabricated and shaped, making them suitable for a wide range of applications. They can be effortlessly cut, drilled, welded, or machined to meet specific project requirements. This adaptability has made steel flat bars a favored choice among manufacturers, fabricators, and DIY enthusiasts alike. Additionally, steel flat bars possess impressive strength and durability properties. Typically crafted from carbon steel, they boast high tensile strength and overall toughness. Consequently, steel flat bars can withstand heavy loads and resist deformation more effectively than other types of bars. Furthermore, they display a heightened resistance to corrosion, making them suitable for outdoor applications or environments exposed to moisture or chemicals. In terms of cost, steel flat bars generally offer a more affordable alternative to stainless steel or alloy steel bars. This cost-effectiveness renders them an attractive option for various projects, particularly in industries requiring large quantities of steel bars. In summary, steel flat bars present numerous advantages over other types of steel bars, including a larger surface area, ease of fabrication, excellent strength and durability, resistance to corrosion, and affordability. These qualities establish steel flat bars as a popular choice across a wide range of applications, from construction and manufacturing to DIY projects.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

8.79KG/M steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords