40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

40Cr / 41Cr4 / 5140 alloy steel specifications

Product Description:

1. Standards

GB 40Cr, 40X, ASTM 5140, BS 520M40, JIS SCR440, NF 42C4, DIN 41Cr4(1.7035)

2. Size:

Round steel bar: Dia. 8-10000mm

Flat steel bar: 10-600*205*1500mm

Length: <12m

3. Machine Capability

Tensile strength (N/mm2Mpa): >=835

Elongation %: >=10

Yield strength: >=540

Hardness: HBS<=179

Reduction of area: >=40%

4. Machinability

Long, gummy chips characterize this alloys machinability. It can be machined in the annealed condition, however condition H1150M will yield best results. Post machining solution treatment of parts will be required prior to final hardening if machining in this condition.

5. Welding

Successfully welded by common fusion and resistance methods, this alloy should not be joined by oxyacetylene welding. AWS E/ER630 filler metal is recommended if required.

6. Process:

EAF+LF+VD+ Forged+ Heat Treatment (Annealed, A Normalized, Q+T)

7. Inspection

100% Ultrasonic according to the test standards: SEP1921-84, GR. 3 CLASS C/C

Chemical Composition:

Chemical Composition(for reference only) (%) | |||||||

C | Si | Mn | Cr | Ni | P | S | Cu |

0.37~0.44 | 0.17~0.37 | 0.50~0.80 | 0.8~1.1 | ≤ 0.03 | ≤ 0.035 | ≤ 0.035 | ≤ 0.30 |

Application:

(1) Generally used for producing the important parts with high strength and good plastic.

(2) After nitrogen treatment, used for producing the important parts with special performance

requirements, such as shafts, gears, fasteners, bolt of large dia steamer etc.

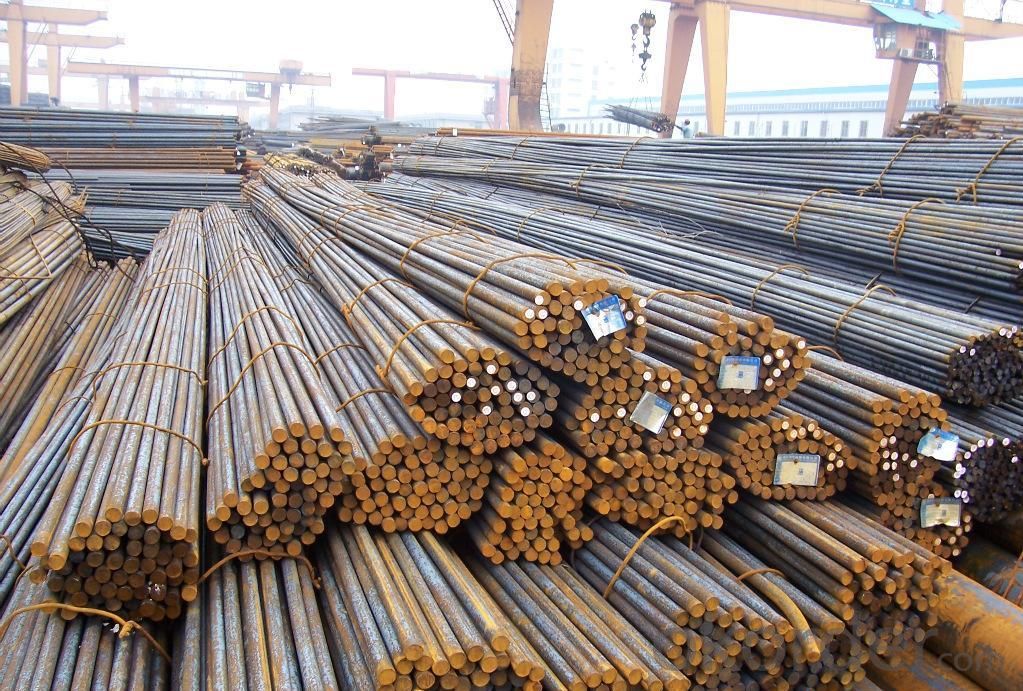

Product Show:

- Q:How does special steel perform in extreme temperature conditions?

- Special steel is designed to perform exceptionally well in extreme temperature conditions. It has a high tolerance for both low and high temperatures, allowing it to maintain its structural integrity and mechanical properties even in the harshest environments. This makes special steel an ideal choice for applications that involve extreme heat or cold, such as aerospace, energy production, and industrial processes.

- Q:How does special steel contribute to reducing product weight?

- Special steel contributes to reducing product weight through its unique properties such as high strength, durability, and lightweight composition. By using special steel in the manufacturing process, designers can optimize the strength-to-weight ratio of the product, allowing for thinner and lighter components without compromising on performance or safety. This reduction in weight not only enhances the efficiency and performance of the product but also reduces material and transportation costs, making it a valuable solution in various industries.

- Q:What are the specific requirements for special steel used in nuclear applications?

- The specific requirements for special steel used in nuclear applications include high resistance to corrosion, excellent mechanical properties, and the ability to withstand high temperatures and neutron irradiation. Additionally, the steel must possess low levels of impurities and be highly resistant to embrittlement. It must also be capable of maintaining its integrity and structural stability over long periods of time, ensuring the safety and reliability of nuclear systems.

- Q:What are the different methods for improving the corrosion resistance of stainless special steel?

- There are several methods for improving the corrosion resistance of stainless special steel. Some of the common methods include alloying the steel with elements such as chromium, nickel, and molybdenum, which enhance its resistance to corrosion. Another method is passivation, which involves treating the steel with an acid solution to remove any surface contaminants and create a protective oxide layer. Coating the steel with materials like paint, powder coating, or electroplating can also improve its corrosion resistance. Additionally, proper cleaning and maintenance practices, such as regular removal of dirt and debris, can help prevent corrosion and maintain the steel's resistance over time.

- Q:What are the applications of special steel in the marine sector?

- Marine grade steel, also known as special steel, finds a wide range of applications in the marine sector. Shipbuilding is one key use of this steel in the industry, as its high resistance to corrosion makes it perfect for constructing ships and other marine vessels constantly exposed to harsh weather conditions and saltwater. Another significant application of special steel in the marine sector is for offshore structures. Materials used in offshore platforms like oil rigs and wind turbines need to withstand the harsh marine environment, including corrosion, high pressure, and extreme temperatures. Special steel's exceptional strength and durability make it the preferred choice for these structures. Furthermore, special steel is employed in the manufacturing of marine equipment and components. For instance, propeller shafts, anchor chains, and underwater pipelines often use special steel due to its excellent mechanical properties and corrosion resistance. Marine engines also rely on special steel to ensure reliable performance and longevity. Moreover, special steel is utilized in the construction of port infrastructure such as piers, docks, and harbor structures. These structures must endure constant exposure to seawater, heavy loads, and dynamic forces, making special steel an ideal material choice for their construction. In conclusion, special steel plays a vital role in the marine sector with its numerous applications. Its corrosion resistance, strength, and durability make it an essential material for shipbuilding, offshore structures, marine equipment, and port infrastructure. The utilization of special steel ensures the longevity and reliability of marine assets operating in harsh marine environments.

- Q:Can special steel be used in the production of musical instruments?

- Yes, special steel can be used in the production of musical instruments. It is commonly used for strings, guitar frets, and some wind instrument components due to its specific acoustic properties and durability.

- Q:How does special steel perform in high-temperature strength?

- Special steel, also referred to as high-temperature steel, is engineered for superior performance in applications requiring high-temperature strength. Unlike standard steels, which can weaken and compromise structural integrity at elevated temperatures, special steel maintains its mechanical properties even in extreme heat conditions. The exceptional high-temperature strength of special steel stems from its distinctive composition. It is typically alloyed with elements like chromium, nickel, and molybdenum, significantly enhancing its resistance to thermal expansion, oxidation, and creep. These alloying elements form stable oxides on the steel's surface, creating a protective layer that prevents further oxidation and corrosion, thus preserving the material's strength and integrity. Furthermore, the microstructure of special steel is vital to its high-temperature performance. Through advanced manufacturing techniques, special steel is crafted with a fine-grained structure, enhancing its resistance to deformation and boosting its creep strength. The fine grains also contribute to its ability to retain mechanical properties at elevated temperatures for extended periods. Moreover, special steel undergoes rigorous heat treatment processes, such as quenching and tempering, which further enhance its high-temperature strength. These processes refine the microstructure and optimize the steel's mechanical properties, including hardness, toughness, and resistance to thermal fatigue. In conclusion, special steel is purposefully designed and engineered to excel in applications requiring high-temperature strength. Its unique composition, microstructure, and heat treatment processes contribute to its exceptional resistance to thermal expansion, oxidation, and creep, ensuring that it maintains its mechanical properties and structural integrity even under extreme heat conditions.

- Q:Can special steel be used in the production of luxury goods?

- Yes, special steel can definitely be used in the production of luxury goods. Luxury goods often require high-quality materials to ensure durability, exclusivity, and overall premium quality. Special steels, such as stainless steel, alloy steel, or carbon steel, offer various desirable properties that make them suitable for luxury goods manufacturing. For instance, stainless steel is widely used in luxury watches, jewelry, and accessories due to its corrosion resistance, shiny appearance, and ability to withstand daily wear and tear. Additionally, certain alloy steels can provide exceptional strength and toughness, making them ideal for luxury car parts, high-end knives, or designer furniture. The use of special steel in luxury goods not only enhances their aesthetic appeal but also contributes to their longevity and value. These materials can be crafted into intricate designs, allowing manufacturers to create unique, one-of-a-kind products that cater to the discerning tastes of luxury consumers. Overall, special steel offers a wide range of qualities that are highly sought after in the production of luxury goods, making it a preferred choice among designers and manufacturers in this industry.

- Q:How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through various ways. Firstly, special steel offers higher strength and durability, allowing manufacturers to create lighter and more efficient designs. This reduces material usage and transportation costs while maintaining the desired product performance. Additionally, special steel's exceptional corrosion resistance minimizes the need for expensive protective coatings or frequent maintenance, saving on long-term costs. Its superior heat resistance also enables manufacturers to use less energy during production processes, resulting in reduced operational expenses. Furthermore, special steel's unique properties, such as high machinability and formability, enhance manufacturing efficiency. This leads to reduced production time, lower labor costs, and increased overall productivity. Overall, the use of special steel in product manufacturing optimizes cost-efficiency without compromising quality, making it an indispensable material for many industries.

- Q:What are the requirements for special steel used in chemical processing?

- The requirements for special steel used in chemical processing include high corrosion resistance, exceptional strength and durability, resistance to high temperatures and extreme pressure, and compatibility with the specific chemicals being processed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

40Cr / 41Cr4 / 5140 alloy steel specifications

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords